HINTS ON MAINTENANCE.

Page 28

If you've noticed an error in this article please click here to report it so we can fix it.

How to Get the Best Out of 'a Vehicle, to Secure Reliability and to Avoid Trouble,

641.—The Spring Slides on the 3-ton Albion.

Owing to the increasing vibration which occurred on a 3-ton Albion lorry, an investigation was made to find the reason. This type of vehicle has sliding slippers for the springs. The oilers on these were filled every day, but without improving the springing. Eventually, the spring slides were taken down and three-quarters of each slide was found to be quite dry. The trouble was at once evident and was caused by the distribution grooves for the oil being gummed up, so that the oil did not circulate over the whole wearing area. The oil was leaving the lubricators and running round the sides of the slides and, to all outward appearances, was lubricating them quite well.

So soon as the slides were thoroughly cleaned, re-assembled and properly oiled, the road shocks were much reduced.

It is, therefore, recommended that any vehicle fitted with slippers of this type should have them removed and cleaned at least every six months, apart from the usual lubrication.

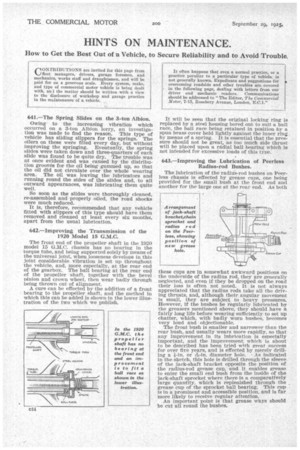

The front end of the propeller shaft in the 1920 model 15 G.M.C. chassis has no bearing in the torque tube, and being supported solely by means of the universal joint, when looseness develops in this joint considerable vibration is set up throughout the vehicle, and, more especially, at the rear end of the gearbox. The ball bearing at the rear end of the propeller shaft, together with the bevel pinion and crown wheel, then wear badly through being thrown out of alignment.

A cure can be effected by the addition of a front bearing to the propeller shaft, and the method hi which this can be added is shown in the lower illustration of the two which we publish. It will be seen that the original locking ring is replaced by a steel housing bored out to suit a ball race, the ball race being retained in position by a spun brass cover held lightly against the inner ring by means of a spring. It is essential that the pressure should not be great, as too much side thrust will be placed upon a radial ball hearing which is not intended for excessive loads of this type.

643.—Improving the Lubrication of Peerless Radius-rod Bushes.

The lubrication of the radius-rod bushes on Peerless chassis is effected by grease cups, one being provided for the small bush at the front end and another for the large one at the rear end. As both

these cups are in somewhat awkward positions on the underside of the radius rod, they are generally neglected, and even if they be dropped on the road their loss is often not noted. It is not always appreciated that the radius rods take all the driving thrusts, and, although their angular movement is small, they are subject to heavy pressures. However, if the bushes be regularly lubricated by the greasers mentioned above, they should have a fairly long life before wearing sufficiently to set up chatter, which, with badly worn bushes, becomes very loud and objectionable.

The front bush is smaller and narrower than the rear bush, and usually wears more rapidly, so that any improvement in its lubrication is especially important, and the improvement which is about to be described has been tried with great success for over five years, and is effected by merely drill ing a i-in. or diameter hole. • As indicated In the sketch, this hole is drilled through the sleeve of the jack-shaft bracket opposite the position of the radius-rod grease cup. and it enables grease to enter the small end bush from the inside of the jack-shaft sprocket where there is a comparatively large quantity, which is replenished through the grease cup of the sprocket ball bearing. This cup is in a prominent and accessible position, and is far more likely to receive regular attention. An important point is that grease whys should be cut all round the bushes.