Combining Strength with in Goods Light Weight Bodywork

Page 44

Page 45

If you've noticed an error in this article please click here to report it so we can fix it.

Reducing Weight—and Minimizing Taxation—in Bottom Frame Construction, Panelling, Tailboards, Doors and Other Components AS goods vehicles are taxed on their unladen weight, the bodybuilder must give particular attention to the weight of his products, because, as a rule, he is expected to build within a specified irnit. The weight allowed for the body varies according to the category of taxation concerned and the weight of the chassis on which the body has to be mounted.

Chassis of similar horse power and load capacity do not weigh the same or have the same length of body space, consequently a body which is well within the limit for one chassis may be too heavy for one of another make if the same specification be repeated.

Information that Helps in Estimating Body Weights.

The bodybuilder, therefore, is keenly interested in chassis weights. He should keep a record not only of the detailed specifications of the bodies built, but also of their weight, so that he has information always .1.eady to hand whereby he is able to form a fairly reliable estimate of the weight of any new body for which an inquiry has been received.

When the weight of a body has been ascertained, a note should be made also of its cubic capacity. When sufficient data have been accumulated, it should be possible to estimate the extra weight required for an additional 12 ins, of length or 6 ins, greater width or headroom for a similar style of body.

Several factors influence the weight of the body. Amongst these are the general design, equipment and finish, style of mounting and the materials used.

Weight is saved if the floor be close to the chassis, so that deep crossbearers are unnecessary. The designing of a lightweight bottom framework is facilitated if the chassis has outrigger brackets. With these brackets and a strong floor laid crosswise, it is possible to dispense with cross-bearers. Another method is to utilize metal cross-bearers, instead of the usual ones of hardwood, either plain or flitch-plated.

When a metal cross-bearer has top flanges, the floorboards are screwed to them. A support for the side pillar, also the bottom side, are made in the following manner :—The length of the channel is such that by separating the sides from the bottom of the channel at each end the sides may be turned at right angles, whilst the bottom piece is turned upwards. A deep bottom side may be bolted directly to the side pieces, or to an angle plate welded to the side pieces. The vertical plate formed by the turned-up bottom piece is utilized as a back plate for the pillar.

Fixing the Floor Above the Level of the Rear Wheels.

Where the floor is above the rear wheels, the upper members of the deep metal cross-bearer consist of a pair of angles to which the floor is attached, and the lower members are plain. The upper and lower parts of the cross-bearer are connected by uprights with an angle piece at the bottom, which affords a bearing on the chassis and is lipped to form a housing for the holding-down clip which embraces the chassis.ends of the upper members are stepped for a bottom side bearing and an additional downward project

ing piece is inserted to give support to the foot of the pillar.

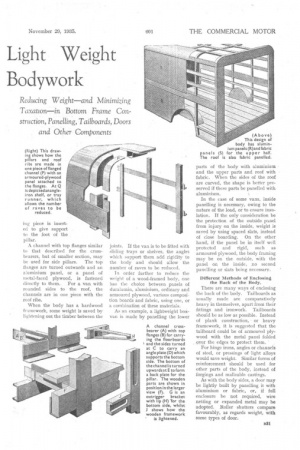

A channel with top flanges similar to that described for the crossbearers, but of smaller section, may be used for side pillars. The top flanges are turned outwards and an aluminium panel, or a panel of metal-faced plywood, is fastened directly to them. For a van, with rounded sides to the roof, the channels are in one piece with the roof ribs.

When the body has a hardwood framework, some weight is saved by lightening out the timber between the

joints. If the van is to be fitted with sliding trays or shelves, the angles which support them add rigidity to the body and should allow the number of raves to be reduced.

In order further to reduce the weight of a wood-framed body, one has the choice between Panels of duralumin, aluminium, ordinary add armoured plywood, various composition boards and fabric, using one, or a combination of these materials.

As an example, a lightweight boxvan is made by panelling the lower parts of the body with aluminium and the upper parts and roof with fabric. When the sides of the roof are curved, the shape is better preserved if these parts be panelled with aluminium.

In the case of some vans, inside panelling is necessary, owing to the

nature of the load, or to ensure insulation. If the only consideration be the protection of the outside panel from injury on the inside, weight is saved by using spaced slats, instead of close boarding. On the other hand, if the panel be in itself well protected and rigid, such as armoured plywood, the body framing may be on the outside, with the panel on the inside, no second panelling or slats being necessary.

Different Methods of Enclosing the Back of the Body.

There are many ways of enclosing the back of the body. Tailboards as usually made are comparatively heavy in themselves, apart from their fittings and ironwork. Tailboards should be as low as possible. Instead of plank construction, or heavy framework, it is suggested that the tailboard could be of armoured plywood with the metal panel folded over the edges to protect them.

For hinge irons, angles or channels of steel, or pressings of light alloys would save weight. Similar forms of reinforcement should be used for other parts of the body, instead of forgings and malleable castings.

As with the body sides, a door may be lightly built by panelling it with aluminium or fabric, or, if full enclosure be not required, wire netting or expanded metal may be adopted. Roller shutters compare favourably, as regards weight, with some types of door.