For DRIVERS, MECHANICS & FOREMEN.

Page 23

If you've noticed an error in this article please click here to report it so we can fix it.

A PRIZE OF TEN skru,LrATGs is awarded each week to the sender of the best letter which we publish on this page ; all others are paid for at the rate of a penny a line, with an allowance for photographs, All notes are edited before being published. Mention pour employer's name, in confidence, as evidence of good faith. Address, D. M. and F., " The Conimel•cial Motor," 7-15, liosebery Avenue, London, E.G. 1.

-Lamps Alight

Light your lamps at 4.26 in London, 4.45 in

Edinburgh, 4.14 in Newcastle, 4.28 in Liverpool, 4.29 in Birmingham, 4.36 in Bristol, and 5.2 in Dublin.

Repairing a Wheel.

The sender of the following communication has been awarded the 10s. prize this week.

[1805] "II.M. " (West Bromwich), writes —"I had a little trouble recently with the wheel-hub of a chaindriven bus chassis, the story of which, and of the way in which it was overcome, will doubtless be of interest to your driver and mechanic readers.

" The ball races of the hub in question were secured in place by an internal nut, which screwed into the inside of the hub. It was locked in place by a spring, ring, which bedded in a groove on the, outside of the hub casting, a projecting end of the wire of which the spring was made being directed through an aperture in the hub and entering a corresponding hole in the nut.

"Unfortunately the thread of the nut was too fine for the work which it had to do, and in consequence it wore away, and the nut dropped out. As it was the thread in the hub that had worn, and not merely that of the nut, any firm was faced with the necessity of cutting a new thread in the hub, and making a new nut to fit. Renewals at short notice were unfortunately out of the question.

"Almost immediately we were up against more trouble, for we found that none of our la-thes,was big enough to 'take the wheel We began to-take steps, therefore, to remove the hub from the wheel, and no light matter it proved. Aftertrying several expedients to accomplishl this end, including a screw-jack and a sledge lia.naniei all without avail, we finally had recourse to the hydraulic press, and with this we had

to use a pressure of 170 tons per sq. in. before the wheel and hub could be persuaded to part company. However, we succeeded in the. end, and rebdred and tapped the hub. Almost immediately the narrow ring of metal between the groove for the locking spring and the end of the casting dropped off, as we had taken away all the metal under the groove in the process of cutting the new thread. .

"To get over this new trouble we had to cut the internal thread half an inch, deeper, and to shorten she distance piece between the two ball bearings accordingly."

Coupling up a Heavy Driving Chain.

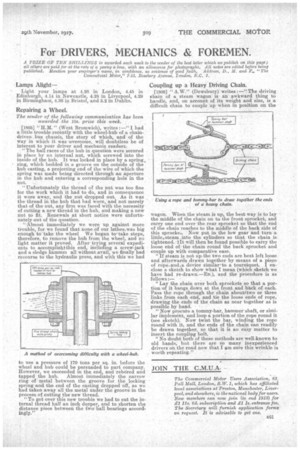

[1806] " A.W." (Dewsbury) writes :—" The driving chain of a steam wagon is an awkward thing to•i handle, and, on account of its weight and size, s a difficult chain to couple up when in position on the

wagon. When the steam is up, the best way ii to lay the middle of the chain on to the front sprocket, and carry one end over the rear sprocket so that the end of the chain reaches to the middle of the back side of this sprocke.. Now put in the low gear and turn -a little steam .into the. cylinders so that the chain is tightened. -3It will then be found possible to carry the loose end of the chain round the back sprocket a-nd couple up with comparative ease.

"If steam is not up. the two ends are best left loose and afterwards drawn together by means of a piece of rope, and,a, device similar,to a tourniquet. I enclose a sketch to show what I mean (which sketch we have had re-drawn.—En.), and the procedure is as follows:—

" Lay the chain over both sprockets so that a portion of it hangs down at the front and back of each. Pass the rope through the chain aboutftwo or three links from each .end, and tie the loose ends of rope, drawing the ends of the chain as near together as is possible .by hand. "Now procure a torrimy-bar, hammer' shaft, or similar implement, and loop a portion of the rope round it (see sketch). Now twist the bar, winding the rope round with it, and the ends of the chain can readily be drawn. together, so that it is an easy matter to insert the coupling bolt.

"No doubt both of these methods are well-known to old hands' but there are so many inexperienced drivers onthe road now. that I am sure this wrinkle is , worth repeating."