THE UPKEEP OF STEAM WAGONS.

Page 12

Page 13

If you've noticed an error in this article please click here to report it so we can fix it.

No. 2.—The Garage and Its Equipment

JUST AS A PROPERLY arranged house is essential to a human being who wishes to live a healthy life, so is a properly devised garage essential to a steam motor wagon if it is to be kapt in first-class condition. It is a fallacy to think that any old shed. will do, so long as it covers the machine. The proper execution of repairs and adjustments, and the smart appearance of the machine, are dependent upon the provision of suitable accommodation.

The building should be of brickwork with a substantial well-drained floor, and plenty of light. The floor of the main portion should' be of concrete— wood gets very dirty and oily, and cannot be properly cleaned—with the necessary provision of drainage. There should be an inspection pit in a, convenient position, so .that a wagon can easily be run over it when other wagons are in the shop. .This pit may be made by digging a hole and letting in a galvanized tank, filling up round it and cementing the edges ; or it can be built up of brickwork and lined with . cement as shown in Fig. 4. _. The top should be substantially covered with hardwood planks fitting flush with the floor.

The size of the building will depend upon the number of wagons, and the equipment will also depend upon the locality. If there are suitable repair shops near, it would not be worth while to do one's own repairs to .a small fleet, for they could probably be done cheaper outside, especially if contracted for at a fixed price for a certain period, as described later..

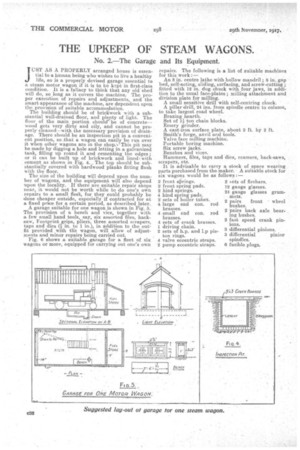

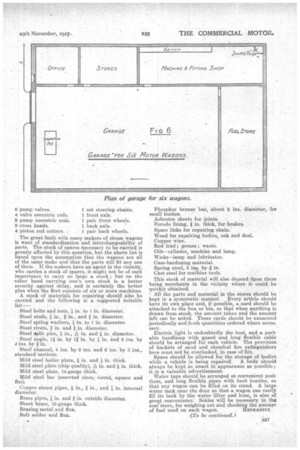

A garage suitable for one wagon is shown in Fig., 5. The provision of a bench and vice, together with a few small hand tools, say, six assorted files, hacksaw, Footprint grips, pliers, three assorted scrapers, taps and dies (1 in. to 1 in.), in addition to the out, fit provided with tile wagon, will allow of adjustments and minor repairs being carried out. Fig. 6 shows a suitable garage for a fleet of six wagons or more, equipped for carrying out one's own

repairs. The following is a list of suitable machines

for this work :— An 8 in. centre lathe with hollow mandril ; 8 in. gap bed, self-acting, sliding, surfacing, and screw-cutting ; fitted with. 12 in. dog chuck with four jaws, in addi

tion to the usual face-.plates ; milling attachment and

division plate for milling. A small sensitive drill with self-centring chuck. A pillar drill, 24 ins, from spindle centre to column, to take largest road wheel.

Brazing h,earth. Set of 11ton chain blacks. Emery grinder. A cast-iron surface plate, about 3 ft. by 2 ft. Smith's forge anvil and tools. Valve face milling machine.

Portable boring machine. Six screw jacks. Benches and vices.

Hammers, files, taps and dies, reamers, hack-saws, scrapers, etc. It is advisable to carry a stock of spare wearing parts purchased from the maker. A suitable stock for six wagons would be as follows :— 2 front siirings.

2 front spring pads.

2 hind springs. 4 hind spring pads.

2 sets of boiler tubes.

4 large end con. rod brasses.

4 small end eon. rod brasses.

4 sets of crank brasses.

1 driving chain. 2 sets of h.p. and 1.p piston rings. 4 valve eccentric straps. 2 pump eccentric straps.

2 iets of firebars. 12 gauge glasses.

24 gauge glasses grummets.

2 pairs front wheel bushes.

2 pairs back axle bear-. ing bushes.

2 fast speed crank pinions.

3 differential pinions.

3 differential pinior spindles.

6 fusible plugs. 8 pump valves. 1 set steering chains.

4 valve eccentric rods. 1 front axle.

2 pump eccentric rods. 1 pair front wheels.

2 cross heads. 1 back axle.

4 piston rod cotters. 1 pair back wheels.

The great fault with many makers of steam wagons is want of standardization and interchangeability of parts. The stock of spares necessary to be carried is greatly affected by this question, but the above list is based upon the assumption that the wagons are all of the same make and that the parts will fit any one of them. lithe makers have an agent in the vicinity, who carries a stock of spares, it might not be of such importance to carry so large a stock ; but on the -other hand carrying one's own stock is a better security against delay, and is certainly the better plan when the fleet consists of six or more machines.

A stock of materials for repairing should also be carried and the following is a suggested suitable list :— Steel bolts and nuts, in. to 1 in. diameter. Steel studs, in., 4 in., and 4 in. diameter. • • Steel spring washers, / in. to 1 in. diameter.

Steel rivets, 4 in. and 4 in. diameter.

Steel split pins, / in., -A, in. and-/ in. diameter.

Steel angle, 14 in. by 14 in. by in. and 3 ins. by .3 ins, by 4 in.

Steel channel, 4 ins. by 2 ins. and 6 ins: by 3 ins., standard sections.

Mild steel boiler plate, 4 in. and 4 in. thick.

Mild steel plate (ship quality), -,3-e in. and 4 in. thick, Mild steel plate, 14-gauge thick.

Mild steel bar (assorted sizes,round, square and flat).

Copper steam pipes, / in., g in., and in. internal diameter.

Brass pipes, 4 in. and 4 in, outside diameter.

Sheet brass, 16-gauge thick.

Brazing metal and flux.

Soft solder and flux. Phosphor bronze bar, about 2 ins, diameter, for small bushes.

Asbestos sheets for joints.

Ferodo lining, 4 in. thick, for brakes.

Spare links for repairing chain.

Wood for repairing bodies, oak and deal.

Copper wire.

Red lead; grease ; waste.

Oils—cylinder, machine and lamp.

Wicks—lamp and lubricator.

Case-hardening material.

Spring steel, 3 ins, by -4 in.

Cast steel for machine tools.

This stock of material will also depend fipen there being merchants in the vicinity where it could be quickly obtained.

All the parts and material in the stores should be kept in a systematic manner. Every article should have its own place and, if possible, a card should be attached to the box or bin, so that when anything is drawn from stock, the amount taken and the amount left can be noted. These cards should be examined periodically and bosh quantities ordered where necessary. Electric light is undoubtedly the best, and a portable handlamp with guard and long flexible cable should be arranged for each vehicle. The provision of buckets of saad and chemical fire extinguishers here must not be overlooked, in case of fire.

Space should be allowed for the storage of bodies while a vehicle is being repaired. A body should always be kept as smart in appearance as possible ; it is a valuable advertisement.

Water taps should be arranged at convenient positions, and long flexible pipes with bent nozzles, so that any wagon can be filled on its stand. A large water tank near the door so that a wagon can easily fill its tank by the water lifter and hose, is also of great convenience: Scales will be necessary in the coarstore, for weighing out and checking the amouter of fuel used on each wagon. IIEPH2EsTu2.