MAKING BEST USE OF THE FORD.

Page 60

If you've noticed an error in this article please click here to report it so we can fix it.

Valuable Advice on Every Phase of Ford Transport which will Appeal to the Owner, Driver and Repairer.

585.—An Emergency Starting Battery.

One of our readers, while out in the country with a Ford truck, had the engine cut-out suddenly and the truck then came gently to rest. The symptoms suggested ignition trouble, which subsequently proved to be the case. The magneto contact was removed, but found to be quite clean and otherwise correct. As there was no battery on board, he was in a quandary as to how a start was to be effected, until a passing cyclist informed him that there was a cycle dealer in a near-by village. The cycle dealer supplied four flash-lamp batteries, but could not provide any wire.

One of the headlamp wires was cut out and a few strands of the wire were • used for coupling two of the batteries together in series, and these two were bound to the steering column for convenience. The remainder, of the wire was used for coupling the batteries to the battery post of the coil box and earth. Switching over to the battery position the engine started at the first swing, and after running a few minutes was switched over to magneto, and continued running.

The journey was completed partly on magneto and partly on the improvised battery, the two reserve batteries not being required. The cause of the trouble was found to be a piece of wire adrift in the transmission case occasionally short-circuiting the magneto coils. This tip for starting and running the engine under similar conditions may prove useful to other readers.

586.—Chassis Frame Repairs.

Either the front or the rear crossmember will occasionally break on the h'ord to-A chassis; usually the front is the one to creel( and break through.

This can be replaced fairly easily and quickly by first removing the radiator and then cutting the heads off the rivets that hold the cross-member to the chassis. Two rivets---one on each side— should be left to keep the cross-member in place. It will be found best to cut off the rivets holding the front corner bracket to the chassis, leaving the bracket on the cross-member. The three rivets holding the corner bracket to the cross-member are awkwardly situated for removal with the cross-member in situ, but can be cut out easily when the cross-member is away from the chassis.

The front axle and spring will then require removing, and the front engineholding-down clip must be removed. The diesels should he securely held by packing or chains end the weight at the front end taken by a jack.

When fitting a new cross-member, a much safer job will be made if the rivets be replaced by the bolts and nuts that hold the controller shaft to the chassie (part Nos. 3,452 and 3,452B). These are a fairly good fit in the holes, and the bolts being drilled for split-,pinning, the nuts can be run right home and awl' locked there. It -will be necessary to B42

omit twobelts on each side—those in front and behind the bottom mudguardstay bolt, as it will be impossible to tighten them. Providing the other bolts be properly tightened, a sound job will result, and if a spot of enamel be applied to the bolt heads they will be inconspicuous.

When the rear cross-member goes it will be far Quicker and easier to remove the body first before attempting anything further. This is easy enough if the body be of the ordinary tumbril tip type, and it has been observed that the rear cross-member is more prone to break with this type of body.

The heads of the rivets are cut off with a large chisel and heavy hammer, the chassis supported at each side, the springs removed, and the axle lowered.

It is usually cheaper to obtain new rear cross-member reinforcements (part No. 1,127, is. 641. retail), as these parts are apt to become bent and distorted by the time they have been removed front the old cross-member.

The rivets should be replaced by crankcase-to-cylinder bolts and nuts or universal-ball-cap setscrews and the same nuts.

It will , be necessary to taper off the heads of the bolts or screws used to secure the reinforcement, as there is °DIY just enough clearance to allow the springs to work. It will be observed that the holes in the inside of the crossmember are countersunk., so that the original rivets would not foul the spring leaves. Wherever possible, the bolts should be drilled for split-pins when the nuts have been tightened, or the ends yell burred over to prevent the nuts slackening back.

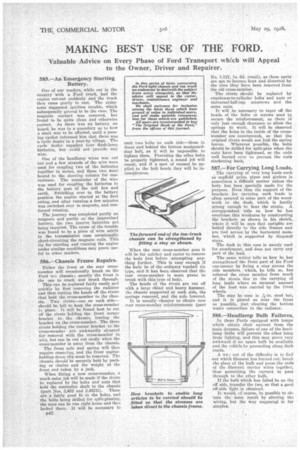

587.—For Carrying Long Loads.

The carrying of very long loads such as scaffold poles, pipes and girders is sometimes a difficult matter unless the body has been specially made for the purpose. Even then the support of the brackets for carrying such loads is often secured to some part of the woodwork Or the dash, which is hardly strong enough to bear the strain. A correspondent tells us how he has overcome this weakness by constructing the brackets as shown in his sketch, where it will be seen that uprights are bolted directly to the side frames and are tied across by the horizontal member, 'which is supported by diagonal stays.

Thedash in this case is merely used for steadyment, and does not carry any Reit of the load.

The same writer tells ns how he has strengthened the front part of his Ford one-tonner by fixing a stay across the side members, which, be tells us, has relieved the cross member from much of the strain due to the carrying of long loads where an unusual amount of the load was carried by the front wheels.

The stay he uses is --in. steel bar, and it is placed as near the front as possible, just clearing the bottom water connection to the radiator.

588.—Headlamp Bulb Failures.

In those Fords equipped with lamps which obtain their current from the main dynamo, failure of one of the headlamp bulbs will prevent the other lamp from lighting, and this may prove very awkward if no spare bulb be available and the vehicle be proceeding along dark roads.

A we; out of the difficulty is to find out which filament has burned out, break the glass of the bulb and press the ends of the filament carrier wires together, thus permitting the current to pass through to the other bulb.

If the bulb which has failed be on the off side, transfer the two so that a good off-side light is obtained.

It would, of course, he possible to obtain the same result by altering the wiring, but the way suggested is far simples.