OVER HERE

Page 62

Page 63

If you've noticed an error in this article please click here to report it so we can fix it.

FOR THE BEER

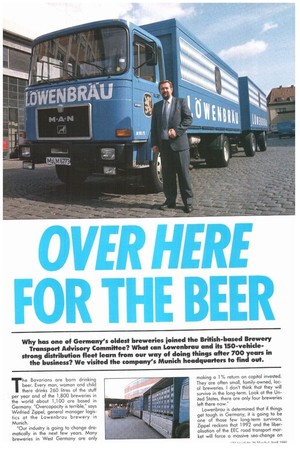

Why has one of Germany's oldest breweries joined the British-based Brewery Transport Advisory Committee? What can Lowenbrau and its 150-vehiclestrong distribution fleet learn from our way of doing things after 700 years in the business? We visited the company's Munich headquarters to find out.

The Bavarians are born drinking beer. Every man, woman and child there drinks 260 litres of the stuff per year and of the 1,800 breweries in the world about 1,100 are based in Germany. "Overcapacity is terrible," says Winfried Zippel, general manager logistics at the Lowenbrau brewery in Munich.

"Our industry is going to change dramatically in the next few years. Many breweries in West Germany are only making a 1% return on capital invested. They are often small, family-owned, local breweries. I don't think that they will survive in the long-term. Look at the United States, there are only four breweries left there now."

Lowenbrau is determined that if things get tough in Germany, it is going to be one of those few long-term survivors. Zippel reckons that 1992 and the liberalisation of the EEC road transport market will force a massive sea-change on the German road haulage industry and that its long-protected working practices will be revolutionised. He has joined the British-based Brewery Transport Advisory Committee (BTAC) to help him prepare for the revolution. What is he hoping to find out?

"I want to exchange information," he says. "I want to know how you distribute your goods in Britain." He also wants to know how much we pay to distribute our goods. He has already started to visit the premises of British distribution companies and operations in BTAC and he says that he is open to return visits in Germany.

"Nothing is secret here," he says, waving his hand around the loading yard the Lowenbrau brewery has been using since the 13th Century. 'We have an open system of management. We talk about what we do. Why not?"

Today, Lowenbrau is making about an 8% return on capital invested and Zip pel and his board are looking for more growth potential. "The big problem in Germany," he says, "is the fixed tariff and price system we have. It is set each year by central Government and all hauliers charge exactly the same amount per kilometre, according to the total weight carried." Zippel is interested in the idea of a completely deregulated freight market and the possibilities offered by something like turning a large fleet over to owner-drivers.

"Our restricted system is an old system, designed to force freight off lorries and onto trains. Trains are very expensive, just like the freight price bands the government sets for hauliers."

The break-point is a 50km radius from the depot. Below that, German operators have to prove that they need to use trucks before attending a training school to gain an operating licence. If they want to run trucks more than 50km from the depot, they have to gain a state-controlled operating licence and then charge according to the fixed rate tariff.

"After 1 992 things will definitely get cheaper for us," says Zippel. Hire-andreward hauliers, he says "do not like the prospect". Lowenbrau, on the other hand, will watch developments with interest.

In many ways, the West German distribution market is old-fashioned. Lowenbrau and its 1,100 fellow brewers are only now getting to grips with the idea of wholesalers, central collection depots, break-bulking and dedicated central distribution warehousing. 'We think that there will be central distribution corn ponies for beer in the future and different breweries will deliver into their warehouses. They will end up stocking more than 600 lines of beer," says Zippel. 'Wholesalers are already starting to come here for supermarket loads," he adds, "and our breweries will just become production centres. My job will be to just organise the wholesalers' collection times."

Despite a highly-organised computer route-planning system and one of the most advanced automatic pallet-loading centres in Europe, Lowenbrau still distributes in three physical bands set out in string on a wall-map in its transport office. The peculiar German licensing system is the root cause of this and the three zones are the city centre of Munich where the brewery has a lot of "tied" restaurants, bars and beer cellars; the suburbs of Munich (called the SBahn region); and everywhere else.

The city centre 10-tonne payload urban delivery vehicles cover about 6,000km a year and return between 20 and 251it/100km in fuel consumption; the 5-Bahn vehicles cover roughly 35,000km a year and the big 24-tonne payload drawbars which do the major trunking routes cover about 80,000km a year returning 4014/100km. The latest trunking rig is based on the MAN 24.331 underfloor chassis and can carry 40 euro-pallets. 'We can often get 38 to 361it/100km with the new MANs," says Zippel. "That is good."

The smallest commercial vehicles in the fleet are Mercedes-Benz 809D vans. Most bodywork on the truck fleet is done by a local bodybuilder called Weinmann, which also runs the Lowenbrau garage on contract as a standalone profit centre. Zippel pays an internally agreed maintenance and servicing rate and the garage is free to do outside work.

All of the Weinmann bodywork is prepared to Lowenbrau's own design in aluminium. The sides of the latest drawbars are solid aluminium panels rather than the curtains and tilts of the older trailers. "The solid sides last longer," says Zippel. "And the drivers prefer them, they are quicker and easier to open." As the bottom panel is pulled down, the top side panel automatically flips up.

Body floors are either 24mm thick or 32mm thick and made from a mixture of hardwood and plastic. Zippel is proud of the minimal damage to his trucks and the low incidence of load spillage and leakage. Many of the eight-year-old Lowenbrau trucks look new. "This is probably because our drivers are on a productivity and bonus scheme," says Zippel. The company says that 200 cases of beer is normal for a two-man delivery round and pays 30 pfennigs for every case delivered over the 200 threshold.

Zippel likes the idea of a highinvestment, high-yield operation. The cutthroat world of Britain's hire-and-reward haulage market at the moment is very far removed from Lowenbrau. The brewery is introducing four-wheel-steer MAN "Maxidistributor" trucks based on the MAN F90, 24-tonne chassis. Zippel says that the increasing use of pedestrian areas, the spread of illegally parked cars and the growth in extensions on the sides of pubs making their car parks smaller means that access is now impossible for his normal drawbars.

The four-wheel-steer MANs have a 15.5-tonne payload and cost DM15,000 (£5,600 approx) more than their conventional counterparts. 'Without the third, extra axle I have fitted at the rear, the Maxidistributor would only have an 8,000 to 10,000kg payload," says Zippel. "I am sure that 30% to 50% of our fleet will be Maxidistributors in five years' time," says Zippel. At the moment, his annual vehicle spend is about DM3 million.

The breakdown of the Lowenbrau fleet now is 60 12-tonners, 60 17tonners and 20 24-tonners. The company has also started putting Mitsubishi M248 "Colento" electric-power pickups into action. The all-electric vans can travel at up to 60km/h with four forward gears. The first models only have a 164kg payload, but before the end of this year Lowenbrau will have one-tonne payload electric vans running around Munich city centre.