D.A.F. RELIES ON BRITISH

Page 42

Page 44

Page 45

If you've noticed an error in this article please click here to report it so we can fix it.

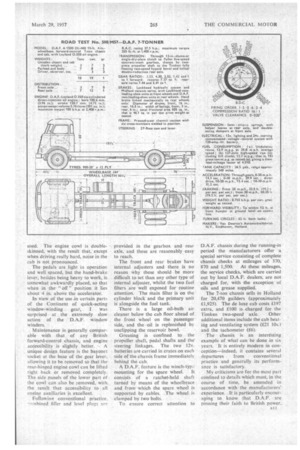

ASIDE of the British export market that rarely receives the credit it deserves is the sale overseas of British engines and licences to build them. One of the largest concerns on the Continent to use British design techniques in this way is the Dutch company, Van Doorne's Auto.mobilefabriek N.V., who manufacture D.A.F. trucks powered by Leyland Comet oil engines.

Having tested one of these vehicles in Holland, I can testify to the. success of this engine when applied to a Continental design. The Leyland unit endows the D.A.F. chassis with ample power for fast haulage, coupled with fuel economy, such as is rarely attained outside Great Britain.

The first. D.A.F. truck was made only six years ago. Since that time a large and extremely well-equipped vehicle factory has been established at Eindhoven, and upwards of 120 chassis a week arc being produced there.

Extensions are still being made and by May the Leyland 0.350 oil engine will be in full-scale production. From what I have seen of this factory. I am .. convinced that the D.A.F.Leyland engine will be up to the standard of units produced by Leyland Motors themselves. The vehicle tested was a 15-ft. 4-in.

wh eel base 7-ton forward-control chassis, in standard form except for the addition of a de luxe cab and two-speed axle. This chassis is available with two other wheelbases, down to 11 ft. 10 in.. and is offered also as a prime mover for use at gross train weights of up to 22 tons. Normalcontrol versions are also available, these having been introduced at the Amsterdam Show last month.

In appearance the chassis layout is conventional, but closer inspection reveals several interesting features which are not found on contemporary British chassis. The frame, for example, is an all-welded assembly, this method of construction having been adopted following the success over the past 20 years or more of D.A.F. all-welded trailers.

. Advanced welding techniques are employed during the assembly of the frame and no instance of frame breakage has ever been reported to the manufacturers.

The engine is unit-mounted with the Fuller five-speed constant-mesh gearbox, and the complete assembly has a four-point rubber mounting arrangement similar to that employed in Leyland vehicles. The gearbox has a D.A.F.-made remote-control linkage which lies on the centre line of the box, but although this brings the gear lever forward into the cab, the position is not by any means ideal, as it is necessary, when changing gear, to stretch over the back of the seat to reach the lever. 'Ibis can become extremely tiring on a long._ journey.

The test vehicle had a Timken twospeed double-reduction axle which is alternative equipment, a Timken single-speed hypoid bevel unit being standard. The two-speed axle has hypoid-bevel primary reduction gearing and two sets of helical secondary reductions, gear changes being eleetrically effected by sliding dogs.

Semi-elliptic springs are used for the suspension at both axles. Each spring has a rubber bush at its front eye, whilst the . rear end is free to slide between a roller and its hanger bracket. The rear springs have a forward inclination of 3+°, which is

When driving the vehicle over varying road surfaces, 1 found for the most part that movement of the seat was excessive and that, combined with the supple front suspension, I tended to be shaken about more than with a rigidly mounted seat. It would appear, however, that this seat was developed at the request of numerous Dutch transport undertakings, so I am prepared to believe that with correct adjustment it would be possible for drivers to become accustomed to this unfamiliar motion between the driving seat and the controls.

Certainly, over the Belgian pave section of the D.A.F. test circuit it was possible to drive at 30 m.p.h. in comparative comfort.

Before my arrival at the works the chassis had been provided with a concrete test load totalling 7 tons 81 cwt., which is representative of a platform body and a 7-ton payload. A distribution check showed that the rear axle was laden to its maximum recommended figure. The chassis had left-hand drive, of course, and Vredestein 9.00-20-in. (12-ply) tyres were used.

Ideal Conditions The vehicle was first taken out to an excellent stretch of level, road near Valkenswaard, about three miles from the Belgian border. Here the brake arid acceleration tests were conducted under virtually ideal conditions.

Stopping distances obtained from 20 m.p.h. to 30 m.p.h. showed a consistent average retardation. Tapley meter readings indicated that there was 20 per cent, difference between the maximum and average deceleration rates, accounted for by delay in the vacuum Servo.

This delay was not, however, noticeable when braking and the general retardation from both speeds was commendably smooth. The hand-brake performance was disappointing, particularly in view of the specially developed linkage in the rear-brake units. The average retardation from 20 m.p.h. was 20 per cent., hut I was told that in -Holland, the legal requirement for a hand brake is II per cent. efficiency with a fully laden goods vehicle.

A comprehensive series of acceleration runs was conducted, going through the gears with high, then low, axle ratios engaged. Up to_20 m.p.h. there was little difference in the times, but up to 30 m.p.h. a saving of 2 sec. was effected by using the low-axle ratio and second, third, fourth and fifth gears.

n1e Direct-drive tests were made with low axle ratio engaged the whole time, and at 10 m.p.h. the engine speed was only 500 r.p.m. (a tachometer was included among the instruments). Below 10 m.p.h., in direct drive, a certain amount of transmission roughness was noted.

It was observed during these tests and subsequent trials that there was a tendency towards exhaust smoking. it appeared to occur mostly during part-load conditions and was probably due to slightly different fuelpump settings compared with those used by Leyland Motors, Ltd.

Consumption Test

An 18:4-mile consumption run starting at the works was then made. The route passed through Eindhoven, Valkenswaard, Leende, Heeze and Geldrop, and took in towns, open roads, slight hills and winding country lanes.

A D.A.F. experimental engineer was driving during this test and, to my mind, he drove the vehicle very hard, maintaining speeds of at least 40 M.p.h. whenever the chance occurred. The result was that the course was completed at an average speed of 29.8 m.p.h., including traffic stops, and the average consumption rate was 12.9 m.p.g. These figures give a time-load-mileage factor of 4,110, which is reasonable enough in view of the conditions.

Ideal as Holland might be for brake and acceleration tests, it is a difficult country in which to conduct hill-climbs and the nearest hills to Eindhoven lie in the province of Limburg, in the Valkenburg region. This is a 60-mile drive from the works.

Themain fuel tank was topped up before leaving the factory, and during a leisurely run down to Limburg an average speed Of approximately 30 m.p.h. was maintained.

• A Rare Hill

The Cauberg, which is just under half a mile long with an • average gradient of 1 in 8+, and sections of up to 1 in 7, was found suitable for brake-fade and engine-power tests.

Having been running with the radiator unblanked for several miles, a check at the bottoni of the Cauberg showed that the radiator temperature was 110° F., whilst the oil temperature was 160° F. The ambient temperature was 57° F.

A brisk climb was then made in 24 minutes, the lowest ratio errrployed being second gear, high. At the top of the hill, the coolant temperature had risen to 124° F., whilst the oil reading was 162° F.

Despite the low initial temperature of the water, the test showed that cooling would be sufficient for operation in mountainous area.S. The reason for the oil temperatures being higher than the water readings is that the oil would not have cooled down to the same extent as the water between the time that the radiator was unblanked and the start of the climb.

The hill was then descended in neutral at a speed of 20 m.p.h. (against the advice of the works driver, who was able to recall several serious accidents on this gradient). The descent took 1-I minutes and only light pressure on the brake pedal was required to restrict the speed. " At the bottom of the hill a crash" stop at 20 m.p.h. produced a Tapley meter reading of 71 per cent., indicating a reduction in efficiency through fade of 12 per cent.

We then returned to the 1 in 7 section and stopped, but it required a hard pull on the hand brake to prevent the chassis.from rolling backwards. With second gear, low axle ratio, engaged, a smooth part-throttle re-start at an engine speed of 600 -r.p.m. was made and was repeated several times.

Adequate Power

There was sufficient power for easy re-starts in second, low, on hills of up to 1 in•6, whilst the use of first gear should make hills of more than 1 in 4 manageable.

On the general slope of the hill it was noticed that while in second gear, low, it was possible to ease the throttle back until the tachometer was registering only 500 r.p.m., at which speed the engine still pulled strongly with no sign of stalling.

The return to Eindhoven was made through Maastricht and the 60-mile journey from Maastricht to the works was completed at an average speed of 35 m.p.h. During this journey was using full throttle for the most part and was able to maintain 50 m.p.h. for long periods along the good traffic-free roads.

From the driver's angle, the D.A.F. has much to commend it, but for the inaccessibility of the gear lever and the flexibility of the driving seat. Both these features, however, would probably become acceptable in time. although I feel sure that some simple form of cranked extension to the gear lever would reduce the amount of contortion needed to change from fourth to top gear, for example.

The vehicle handles well the steer.ing ratio being rather similar to that employed on British 7-tonners. although a larger steering wheel is used. The engine cowl is doubleskinned, with the result that, except when driving really hard, noise in the cab is not pronounced.

The pedals are light in operation and well spaced, but the hand-brake lever, besides being heavy to work, is somewhat awkwardly placed, so that when in the" off " position it lies about 4 in. above the accelerator.

In view of the use certain parts of the Continent of quick-acting window-winding gear, I was surprised at the extremely slow action of the D.A,F. window winders.

Maintenance is generally comparable with that of any British forward-control chassis, and engine accessibility is slightly better. •, A unique design feature is the bayonet socket at the base of the gear lever, allowing it to be removed so that the rear-hinged engine cowl can be lifted right hack or removed completely. The side panels of the lower part of the cow! can also be removed, with the result that accessibility to all engine auxiliaries is excellent.

Following conventional practice, -nrnhincd filler and level plugs arc provided in the gearbox and rear axle, and these are reasonably easy to reach.

The front and rear brakes have internal adjusters and there is no reason why these should be more difficult to set than any other type of internal adjuster, whilst the two fuel filters are well exposed for routine attention. The Main filter is on the cylinder block and the primary unit is.alongside the fuel tank.

There is a large oil-bath air cleaner below the cab floor ahead of the front wheel on the passenger side, and the oil is replenished by unclipping the reservoir bowl.

Greasing is confined to the propeller shaft, pedal shafts and the steering linkages. The two I2v. batteries are carried in crates on each side of the chassis frame immediately behind the cab. •

A D.A.F. feature is the winch-typo mounting for the spare wheel. It consists of a ratchet-held shaft turnedby means of the wheelbrace and from which the spare wheel is supported by cables. The wheel is damped by two bolls'.

To ensure correct attention to D.A.F. chassis during the running-in period the manufacturers offer a special service consisting of complete chassis checks at mileages of 370, 870 and 1,500. At these mileages, the service checks, which are carried Out by local D.A.F. dealers; are not charged for, with the exception of oils and grease supplied.

The 7-ton chassis sells in Holland for 20,470 guilders (approximately £1,925). The de luxe cab costs £197 extra, and £100 is charged for the Timken two-speed axle, Other additional items include the cab heating and ventilating system (£21 105.) and the tachometer The chassis • is an interesting example of what can be done in six years. It is entirely modern in conception—indeed, it contains several departures from conventional practice and generally its performance is satisfactory.

My criticisms are for the most part confined to details which must, in the course of time, be amended in accordance with the manufacturers' experience. It is particularly encouraging to know that D.A.F. are pinning their faith to British power.