LOGGING

Page 64

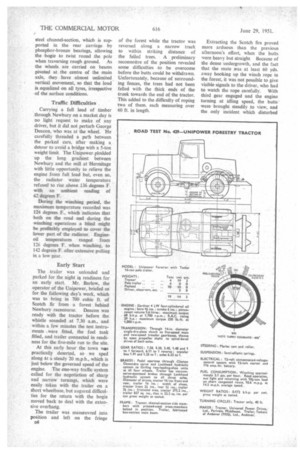

Page 65

Page 66

Page 67

If you've noticed an error in this article please click here to report it so we can fix it.

n FOUR GAL Powered by the Gardner Four-cylindered Oil Engine the Unipower Forester Proves an Ideal Logging Outfit under

Difficult Conditions

By L. J. COTTON, M.I.R.T.E.

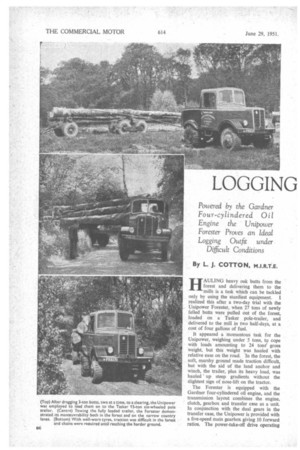

HAULING heavy oak butts from the forest and delivering them to the mills is a task which can be tackled only by using the sturdiest equipment. I realized this after a two-day trial with the Unipower Forester, when 27 tons of newly felled butts were pulled out of the forest, loaded on a Tasker pole-trailer, and delivered to the mill in two half-days, at a cost of four gallons of fuel.

It appeared a momentous task for the Unipower, weighing under 5 tons, to cope with loads amounting to 24 tons' gross weight, but this weight was hauled with relative ease on the road. In the forest, the soft, marshy ground made traction difficult, but with the aid of the land anchor and winch, the trailer, plus its heavy load, was hauled' up steep gradients without the slightest sign of nose-lift on the tractor.

The Forester is equipped with the Gardner four-cylindered oil engine, and the transmission layout combines the engine, clutch, gearbox and transfer case as a unit. In conjunction with the dual gears in the transfer case, the Unipower is provided with a five-speed main gearbox giving 10 forward ratios. The power-take-off drive operating the winch also uses the main gear ratios and has, therefore, five forward and a reverse gear.

Naturally, the frame of the tractor is heavy and the addition of the winch sub-frame assists in strengthening the rear section. The winch roller-gear and land anchor are combined on this sub-frame, so that the heavy stresses set up during roping are concentrated on the subframe and not passed to the vehicle chassis. The gears and drums of this self-contained winch unit are of massive proportions and, equipped with 100 yds. of cable, are capable of exerting a pull of nearly 30 tons. As with the rest of the winch design, the roller gear is strongly constructed and the auxiliary equipment includes a roping-forward bracket and wheel, and there is a roller gear permanently mounted on the front bumper-bar.

A development feature of the Forester is an overframe, constructed from heavy-gauge steel, which supports the transversely mounted fuel and vacuum tanks and other components which would normally have separate fixings. The 45-gallon fuel tank, arranged behind the cab, has sufficient capacity under normal conditions for a fortnight's operation.

Because of a hitch in map reading, my test vehicle was not tracked down until late morning, when I discovered it in the heart of a forest pulling 2I-3-ton oak butts to a clearing in readiness for loading. Ground conditions were difficult, and the tractor with 11,000 miles to its credit, plus a set of well-worn crosscountry tyres, was equipped with chains at the rear axle to combat the soft marsh surface.

It made light work of roping, and, as proof, two butts were arranged in tandem and winched into the clearing with third gear engaged. Conditions were made still more difficult by the build-up of soft earth and scrub during roping operations, and it took over an hour to pull six heavy butts an average distance of 300 yds. into the clearing.

In this distance there were many stops for rearrangement of the chains to steer the butts round stools, and here I found the advantage of the large rear window which affords full visibility of the winch drums and cable during roping operations. Undoubtedly, the driver can find little to criticize in the front, side or rear visibility of the Unipower cab, and the full-drop window at the rear is an advantage when he has to rely on audible signals from his mate at the end of the rope in the thick of the forest.

Four-wheel-drive was required to climb some of the loose banks, and the 40-ft. turning circle of the tractor proved adequate for close manceuvring in the forest. The tractor used in the trials had a pressed-steel pan over the front-drive housing, which could prove a vulnerable spot in forestry work. This is now being changed in current design for a hard nose, which will relieve the driver of looking out for stumps between the wheels During the l hours of tough winching the tractor used 4 pts. of fuel, but under average conditions the fuel-consumption rate decreased to 2 pts. per hour. The fellers had cleaned the oak butts to a nicety and they were rolled up the ramps on to the Tasker 15-ton trailer in almost record time The articulation of the fourwheeled tandem carriage of the trailer bogie proved ideal when working along the deeply rutted track between the forest and the road. The Tasker trailer used had a square backbone, fabricated from steel channel-section, which is supported in the rear carriage by phosphor-bronze bearings, allowing the bogie to twist round the pole when traversing rough ground. As the wheels are carried on beams pivoted at the centre of the main axle, they have almost unlimited, vertical movement, so that the load is equalized on all tyres, irrespective of the surface conditions.

Traffic Difficulties Carrying a full load of timber through Newbury on a market day is no light request to make of any driver, but it did not perturb George Deacon, who was at the wheel. He carefully threaded a path between the parked cars, after making a detour to avoid a bridge with a 5-ton weight limit. The Unipower plodded up the long gradient between Newbury and the mill at Hermitage with little opportunity to relieve the engine from full load but, even so, the radiator water temperature refused to rise above 136 degrees F. with an ambient reading of 62 degrees F.

During the winching period, the maximum temperature recorded was 124 degrees F., which indicates that both on the road and during the winching operations a blind might be profitably employed to cover the lower part of the radiator. Engineoil temperatures ranged from 126 degrees F. when winching, to 142 degrees F. after extensive pulling in a low gear.

Early Start The trailer was unloaded and parked for the night in readiness for an early start. Mr. Barlow, the operator of the Unipower, briefed us for the following day's work, which was to bring in 700 cubic ft. of Scotch fir from a forest behind Newbury racecourse. Deacon was ready with the tractor before the whistle sounded at 7.30 a.m., and within a few minutes the test instruments were fitted, the fuel tank filled, and trailer connected in readiness for the five-mile run to the site.

At this early hour the town was practically deserted, so we sped along tit a steady 20 m.p.h., which is just below the governed speed of the engine. The one-way traffic system called for the negotiation of sharp and narrow turnings, which were easily taken with the trailer on a short wheelbase, but augured difficulties for the return with the bogie moved back to deal with the extensive overhang.

The trailer was manoeuvred into position and left on the fringe D8 of the forest while the tractor was reversed along a narrow track to within striking distance of the felled trees. A preliminary reconnoitre of the position revealed some difficulties to be overcome before the butts could be withdrawn. Unfortunately, because of surrounding fences, the trees had not been felled with the thick ends of the trunk towards the end of the tractor. This added to the difficulty of roping two of them, each measuring over 60 ft. in length. Extracting the Scotch firs proved more arduous than the previous afternoon's effort, when the butts were heavy but straight Because of the dense undergrowth, and the fact that the mate was at least 60 yds. away hooking up the winch rope in the forest, it was not possible to give visible signals to the driver, who had to watch the rope carefully. With third gear engaged and the engine turning at idling speed, the butts' were brought steadily to view, and the only incident which disturbed

the smoothness of the procedure was the rope, which bound in between coils on the drum. A simple device for threading the rope evenly on the drum would be welcomed by all forestry tractor operators. It would save time and prevent the kink that eventually results in wire chafing.

Once the butts were drawn up behind the tractor, it was relatively easy for the Unipower to tow them down to the trailer. The pole-trailer wheelbase was lengthened by withdrawing the attachment pins of the bogie and towing the front bolster forward to the requisite position. At this point, it was decided the load should be shortened to avoid difficulties in manceuvring through the town. This precaution was justified because, with several feet sawn off the trunks, there was still little room to spare at the rear when driving round the right-angle turn in the centre of the market place.

Each time the tractor is reversed after winching, the land anchor has to be raised. It is a task for the superman to tackle single-handed on soft ground, and some form of in

built winching device would save a lot of hard labour. Although the operation might take a few seconds longer, all the heavy lifting would be alleviated. A lifting device was fitted to one tractor, but the driver preferred to use manual effort and

save a little time. The land anchor weighs approximately 5 cwt., which is equivalent to the combined weight of two commercial-vehicle wheels.

It was not possible to carry all the 700 cubic ft. in one load, but five of the heaviest trunks and two short ends, aggregating 10i tons, were winched up the ramps on to the bolsters. This operation was prolonged because some of the load had to be turned on the bolsters to prevent movement.

After the Unipower was hitched up to the trailer, it made light work of hauling its load on to a hard surface. From a standing start, the combined unit was accelerated to 20 m.p.h. in just over a minute, but there was no further opportunity of checking this time or testing the brake perfcirrnance. Undoubtedly, the retardation was good, but with such a difficult load as the long butts, it would be hazardous to attempt a full brake application from speed along the narrow congested roads which exist in the Newbury area.

The level of fuel in the tank was replenished at regular intervals throughout the winching operations and, in comparison with the heavier work on the previous afternoon, the

consumption rate worked out to 2.1 pints per hour. On the road, the consumption was measured on the outward and return journeys, the run back to the mill being extremely arduous because of the town congestion and incline. For general short haulage, such as this, the Unipower requires rather more fuel than on the longer runs to the Midlands and South when it is delivering sawn timber to factories. On short haulage, the consumption -rate works out to 10.6 m.p.g., but for delivery work over average roads, the Unipower would require approximately a gallon of fuel to every 15 miles run.

The total quantity of fuel used in the afternoon and following morning's work totalled slightly under four gallons, and, as usual with these fogging outfits, the engine was stationary only for the lunch break.