Tipping thi balance foi an auto bo3

Page 30

Page 31

Page 33

If you've noticed an error in this article please click here to report it so we can fix it.

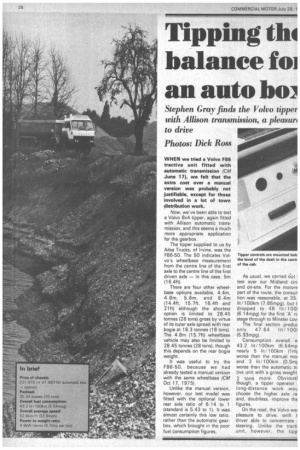

Stephen Gray finds the Volvo tipper with Allison transmission, a pleasur• to drive Photos: Dick Ross

WHEN we tried a Volvo F86 tractive unit fitted with automatic transmission (CM June 17), we felt that the extra cost over a manual version was probably not justifiable, except for those involved in a lot of town distribution work.

Now, we've been able to test a Volvo 8x4 tipper, again fitted with Allison automatic transmission, and this seems a much more appropriate application for the gearbox.

The tipper supplied to us by Aiisa Trucks, of Irvine, was the F86-50. The 50 indicates Volvo's wheelbase measurement from the centre line of the first axle to the centre line of the first driven axle — in this case, 5m (16.4ft).

There are four other wheelbase options available, 4.4m, 4.8m, 5.6m, and 6.4m (14.4ft, 15.7ft, 18.4ft and 21ft) although the shortest option is limited to 28.45 tonnes (28 tons) gross by virtue of its outer axle spread with rear bogie at 18.3 tonnes (18 tons). The 4.8m (15.7ft) wheelbase vehicle may also be limited to 28.45 tonnes (28 tons), though this depends on the rear bogie weight.

It was useful to try the F86-50, because we had already tested a manual version with the same wheelbase (CM Oct 17, 19751

Unlike the manual version, however, our test model was fitted with the optional lower rear axle ratio of 6.14 to 1 (standard is 5.43 to 1). It was. almost certainly this low ratio, rather than the automatic gearbox, which brought in the poor fuel consumption figures.

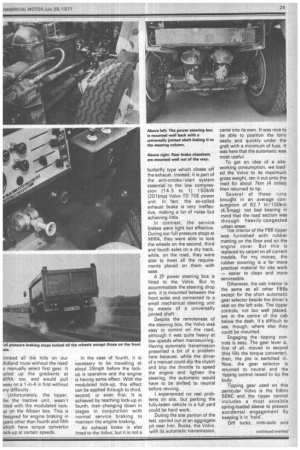

As usual, we carried Out • test over our Midland circ and on-site. For the motory part of the route, the consur tion was reasonable, at 35. lit/100km (7.86mpg), but t dropped to 46 lit /1001 (6.14mpg) for the first 'A' rc stage through to Minster Loyl

The final section produc only 47.64 lit/1001 (5.93mpg).

Consumption overall IA 43.2 lit/100km (6.54mp nearly 5 lit/100km (1mF worse than the manual moi and 3 lit/100km. (0.5m1 worse than the automatic tr; tive unit with a gross weight 2 tons more. Obviousl though, a tipper operator long-distance work wou choose the higher axle ra and, doubtless, improve the figures.

On the road, the Volvo we; pleasure to drive, with t driver able to concentrate steering. Unlike the tracti unit, however, the tipp :limbed all the hills on our flidland route without the need o manually select first gear. It ailed up the gradients at V1IRA, too, and would pull away on a 1-in-4 in first without my difficulty.

Unfortunately, the tipper, ike the tractive unit, wasn't itted with the modulated lockip on the Allison box. This is designed for engine braking in gears other than fourth and fifth which have torque convertor lock-up at certain speeds. In the case of fourth, it is necessary to be travelling at about 28mph before the lockup is operative and the engine is having some effect. With the modulated lock-up, this effect can be applied through to third, second, or even first. It is achieved by reaching lock-up in fourth, then changing down in stages in conjunction with normal service braking to maintain the engine braking.

An exhaust brake is also fitted to the Volvo, but it is not a butterfly type which closes off the exhaust. Instead, it is part of the anti-smoke /start system essential to the low compression (14.5 to 1) 150kW (201 bhp) Volvo TD 70E power unit. In fact, the so-called exhaust brake is very ineffective, making a lot of noise but achieving little.

In contrast, the service brakes were light but effective. During our full pressure stops at MIRA, they were able to lock the wheels on the second, third and fourth axles on a dry track, while, on the road, they were able to meet all the requirements placed on them with ease.

A ZF power steering box is fitted to the Volvo. But to accommodate the steering drop arm, it is mounted between the front axles and connected to a small mechanical steering unit by means of a universally jointed shaft.

Despite the remoteness of the steering box, the Volvo waS easy to control on the road, although it was quite heavy at low speeds when manoeuvring. Having automatic transmission presented a bit of a problem here because, while the driver of a manual could dip the clutch and blip the throttle to speed the engine and lighten the steering, the automatic would have to be shifted to neutral before revving.

I experienced no real problems on site, but parking the fully-laden vehicle in a full yard could be hard work, During the site portion of the test, carried out at an aggregate pit near lver, Bucks, the Volvo, with its automatic transmission, came into its own. It was nice to be able to position the lorry easily and quickly under the grab with a minimum of fuss. It was here that the automatic was most useful.

To get an idea of a siteworking consumption, we loaded the Volvo to its maximum gross weight, ran it out onto the road for about 7km (4 miles) then returned to tip.

Several of these runs brought in an average consumption of 62.7 lit/100km. (4.5mpg): not bad bearing in mind that the road section was through heavily congested urban areas.

I he interior of the F86 tipper was furnished with rubber matting on the floor and on the engine cover. But this is replaced by carpet on all current models. For my money, the rubber covering is a far more practical material for site work — easier to clean and more serviceable.

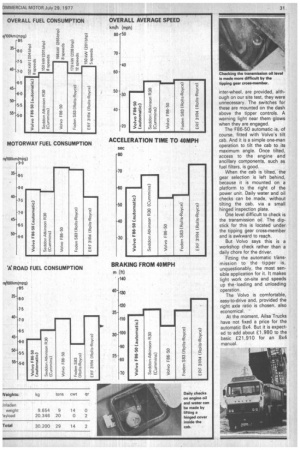

Otherwise, the cab interior is the same as all other F86s except for the short automatic gear selector beside the driver's seat on the left side. The tipper controls, not too well placed, are in the centre of the cab below the dash. It's difficult to see, though, where else they could be mounted.

Engaging the tipping controls is easy. The gear lever is, first of all, moved to second (this fills the torque converter), then, the pto is switched in. Now, the gear selector is returned to neutral and the tipping control raised to tip the body.

Tipping gear used on this particular Volvo is the Edbro 6ENC and the tipper control includes a most ,sensible spring-loaded sleeve to prevent accidental engagement by keeping it in 'hold'.

Diff locks, inter.-axle and inter-wheel, are provided, although on our site test, they were unnecessary. The switches for these are mounted on the dash above the tipper controls. A warning light near them glows when they are engaged.

The F86-50 automatic is, of course, fitted with Volvo's tilt cab. And it is a simple one-man operation to tilt the cab to its maximum angle. Once tilted, access to the engine and ancillary components, such as fuel filters, is good.

When the cab is tilted, the gear selection is left behind, because it is mounted on a platform to the right of the power unit. Daily water and oil checks can be made, without tilting the cab, via a small hinged inspection plate.

One level difficult to check is the transmission oil. The dipstick for this is located under the tipping gear cross-member and is awkward to reach.

But Volvo says this is a workshop check rather than a daily chore for the driver.

Fitting the automatic transmission to the tipper is, unquestionably, the most sensible application for it. It makes light work on-site and speeds up theloading and unloading operation.

The Volvo is comfortable, easy-to-drive and, provided the right axle ratio is chosen, also economical.

At. the moment, Ailsa Trucks have not fixed a price for the automatic 8x4. But it is expected to add about £1,980 to the basic £21910 for an 8x4 manual.