Seven-compartment Tanker for Aviation Service

Page 18

If you've noticed an error in this article please click here to report it so we can fix it.

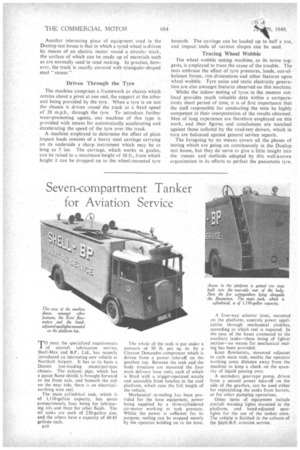

T0 meet the specialized requirements of aircraft lubrication service, Shell-Mex and B.P., Ltd., has recently introduced an interesting new vehicle at Northolt Airport. It has as its basis a Dennis low-loading mur&ipal-type chassis. The exhaust pipe. which has a gauze flame shield, is brought forward to the front axle, and beneath the cab on the near side, there is an electricalearthing wire reel.

The main cylindrical tank, which is of 1,110-gallon capacity, has seven compartments, four being for lubricating oils and three for other fluids. The oil tanks are each of 230-gallon size, and the others have a capacity of 60-65 gallons each.

alO The whole of the tank is put under a pressure of 50 lb. per sq. in, by a Clayton Dewandre compressor which is driven from a power take-off on the gearbox top. Between the tank and the body structure are mounted the four main delivery hose reels, each of which is fitted with a trigger-operated nozzle and accessible from hatches in the roof platform, which runs the full length of the vehicle.

Mechanical re-reeling has been provided for the hose equipment, power being supplied by a three-cylindered air-motor working at tank pressure. Whilst the power is sufficient for its purpose, reeling can be stopped merely by the operator holding on to the hose. A four-way selector lever, mounted on the platform, controls power application through rnechankal clutches, according to which reel is required. In the case of the hoses connected to the auxiliary tanks—these being of lighter section—no means for mechanical reeling has been provided.

Kent flowmeters, mounted adjacent to each main tank, enable the operator working some distance away from the machine to keep a check on the quantity of liquid passing over.

A secondary gear-type pump, driven from a second power take-off on the side of the gearbox, can be used either for replenishing the tanks from barrels, or for other pumping operations.

Other items of equipment include aircraft warning lights mounted in the platform, and hand-adjusted spotlights for the use of the tanker crew. The vehicle is finished in the colours of the Shell-B.P. aviation service.