TRACTORS FOR THE LINCOLN TRIALS.

Page 15

Page 16

Page 17

Page 18

If you've noticed an error in this article please click here to report it so we can fix it.

Main Features of the Crawley, Emerson and Fordson Models.

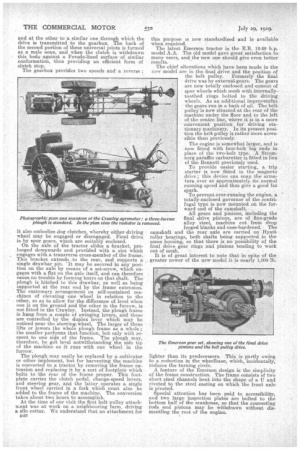

THERE IS A SHARP division in tractor design as between the self-contained type and the direct-haulage machine, and in examining the Crawley self-contained agrimotor, we could not resist the temptation to put the important question, "Why Choose a self-contained type ?" to its manufacturer and designer, who happens, as a matter of fact, additionally to be a farmer of some 25 years' experience. There appear to be two fairly strong reasons which combined to form his decision along the lines exemplified by this machine. In the first place, there is the difficulty which, it. must be admitted, even the best-arranged equipments of tractor and self-lift plough are under, that the driver of the:tractor must of necessity turn round if he is to observe the quality of work which the plough is doing ; _secondly, in such an outfit the plough is held in the ground only by its own weight in addition to the natural suction.effeet of the shares. Mr. Crawley's idea in designing his agrimotor was' first,'" to. have the, driver sit at the extreme, rear, thus having under his eye the whole of this machine and also the work which it is at any moment encompassing; secondly, by balancieg roughly the machine on two wheelS, the torque reaction due to the driving effect tends always to force the ploughs into the' soil. We may now turn, with interest to examine in some detail the machine designed on lined in keeping with these considerations. A short, rectangular framework supports the engine and the whole of the transinission mechanism of this agrimotor. It is terminated at the front just before the engine and at the rear by that cross-ntember,which may be seen in the photographic plan view immediately behind•the rear wheels. The driver's seat, control gear' ,steering mechanism, and the rear supporting. wheel of the plough are all carried by an extension:which is bolted to this main frame. The engine.occupies-the other position, right in front, and is renderecPparticularly iccessible by the Renault type of bonnet, the.radiator being situated behind the engine over 'the flywheel The power unit is a 30 lip., four-cylinder,14 in. bore by 511in, stroke, equipped with the usual.accessories, including Thomson-Bennett' high-tension magneto. There would not appear to be a liability to any-considerable degree of frame whip in the' construction employed in this tractor, but the designers have, nevertheless, thought fit to4suspend the engine at three points, and thus eliminate even'any slight risk of distortion which may exist. We examined some

of the engine components, a characteristic of which is their robust construction, but beyond this there is nothing about the power unit which calls for special comment.

The radiator, however, is of unusual design. The cooling portion is an ordinary block of vertical gilled tithes ; the top headeris a plain casting, but the lower one is built to form a, casing over the flywheel, upon the exterior of which are secured the fan blades. This lower casting of the radiator is thus carried right down below any poilit on the engine. A sub

stantial drain cock is fitted at thi bottom, thus ensuring complete, drainage of the circulating system—an important point in tractors which have to be left out in the field overnight.

The clutch is a Ferodo-lined cone, and behind it is a pair of universal joints of special design. To the clutch centreis secured a concave disc, to the rim of which is fastened a fibre disc. A. short flanged shaft is bolted at one end to the centre of this disc, and at the other to a similar one through which the drive is transmitted to the gearbox. The back of the second portion of these universal joints is formed as a male cone, and when the clutch is withdrawn this beds against a Ferodo-lined surface of similar conformation, thus providing an efficient form of clutch stop.

The gearbox provides two speeds and a reverse ; it also embodies dog clutches, whereby either driving wheel may be engaged or disengaged. Final drive is by spur gears, which are suitably enclosed. On the axle of the tractor slides a ;bracket, prolonged downwards and provided with a slot which engages with a transverse cross-member of the frame. This bracket extends -to the rear, and supports a single drawbar pin. •It may be secured in any position on the axle by means of a set-screw, which engages with a flat on the axle itself, and can therefore cause no trouble by forming burrs on that shaft. The plough is hitched to this drawbar, aS well as being supported at the rear end by the frame extension. The customary arrangement on self-contained machines of elevating one wheel in relation to the other, so as to allow for the difference of level when one is on the ground and the other in the furrow, is not fitted in the Crawley. Instead, the plough frame is hung from a couple of swinging levers, and these are controlled by the duplex lever which may be noticed near the steering.wheel. The larger of these lifts or lowers the whole plough frame as a whole ; the smaller performs that function, but only with respect to one side of the frame. The plough may, therefore, be got level notwithstanding the side tip of the machine as it runs with one wheel in the furrow.

The plough may easily be replaced by a cultivator or other implement, but for harvesting the machine is converted to a tractor by removing the frame extension and replacing it by a sort of footplate which bolts to -the rear of the frame proper. This footplate carries the clutch pedal, change-speed levers, and steering gear, and the latter operates a single front wheel carried in a fork which must also be added to the frame of the machine. The conversion takes about two hours to accomplish.

At the time of our visit the first belt pulley attachment was at work on a neighbouring farm, driving a silo cutter. We understand that an attachment for this purpose is now standardized and is available when required.

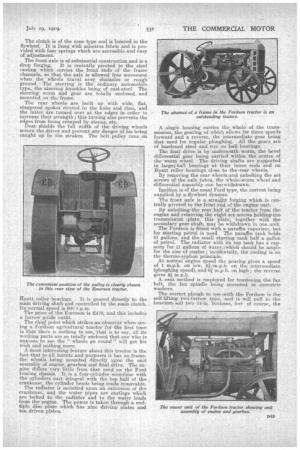

The latest Emerson tractor is the E.B. 12-20 h.p. model A.A. The old model gave great satisfaction to many users, and the new one should give even better

results.

The chief alterations which have been made in the new model arc in the final drive and the position of the belt pulley. Formerly the final drive was by externalgears. The gears are now totally enclosed and consist of spur wheels which mesh with internally toothed rings bolted to the driving wheels. As an additional improvemke.

the gears run in a bath of oil. The belt

pulley-is now situated at the rear of the machine under the floor and to the left

of the centre line, where it is in a more cenvenient position for driving stationary machinery. In its present position the belt pulley is rather more accessible than previously.

The engine is someithat larger, and is now fitted with four-bolt big ends in place of the two-bolt type. A Stromberg paraffin carburetter is fitted in lieu of the Bennett previously used. To provide easier starting, a trip . starter is now fitted in the magneto drive ; this device can snap the arma ture over at approximately its normal running speed and thus give a good fat spark. To prevent over-running the engine a totally-enclosed governor of the cenerifugal type is now mounted on the forward end of the camshaft..

All gear,s and pinions, including the final drive pinions are of fine-grade alloy steel, machine cut from drop forged blanks and case-hardened. The camshaft and the rear axle are carried on Hyatt roller bearings, both shafts being supported in the sa.rne houSing, so that there is no possibility of the final drive gear rings and pinions tending to work out of mesh.

It is of great interest to note that in spite of the e. greater power of the new model it is nearly 1,000 lb.

lighter than its predecessors. This is pertly owing to a reduction in the wheelbase, which, incidentally, reduces the turning circle.

A feature of the Emerson design is the simplicity of the frame construction. The frame consists of two short steel channels bent into the shape of a LT and riveted to the steel casting on which the front axle is pivoted.

Special attention has been paid to accessibility, and two large inspection plates are bolted to the bottom half of the crankoae,e, so that the connecting rods and pistons may be withdrawn without dismantling the rest of the engine. The clutch is of the cone type and is located in the flywheel. It is lined with asbestos fabric and is provided with four springs which are accessible and easy of adjustment.

The front axle is of substantial construction and is a drop forging. It is centrally pivoted to the steel casting which carries the 'front ends of the frame channels, so that the. axle is allowed free movement when the wheels travel over obstacles or rough ground. The steering is the ordinary automobile type, the steering knuckles being of cast-steel. The steering worm and gear are totally enclosed_ and mounted on the frame.

The rear wheels are built up with wide, flat, staggered spokes riveted to the hubs and rims and the latter are turned over at the edges in order to increase their strength ; this turning also prevents the edges from being crimped by stones, etc. Dust shields the full width of the driving wheels screen the driver and prevent any danger of his being caught up by the atrakes. The belt pulley runs on

Ffyatt roller bearings. It is geared directly to the main driving shaft and controlled by the main clutch., Its normal speed is 900 r.p.m. The price of the Emerson is 2470, and this includea furrow guide outfit.

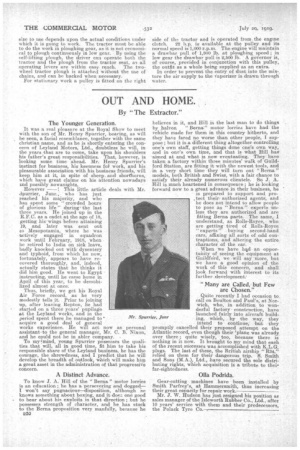

The chief point which strikes an observer when seeing a Fordson agricultural tractor for the first time is that there is nothing to see, that is to say, all its working parts are so totally enclosed that one who is anxious to see the " wheels go round" will get his wish and nothing more.

A inost interesting feature about this tractor is the fact that to all intents and purposes it has no frame, the wheels being mounted directly upon the unit assembly of engine, gearbei and final drive. The engine differs very little from that used on the Ford touring chassis. It is a four-cylinder monobloc with the cylinders cast integral with the top half of the, crankcase, the cylinder heads being made removable.

The radiator is mounted upon an extension of the crankcase, and the water pipes are castings which are bolted to the radiator and to the water leads from the engine. The power is taken through a multiple disc plate which has nine driving -plates and ten driven plates.

A single housing carries the whole of the transmission, the gearing of which allows for three speeds forward and a reverse, the intermediate gear being that used for regular ploughing. All the gears are of hardened steel and run on ball bearings.

The final drive is by underneath worm, the bevel differential gear being carried within the centre of the worm wheel. The driving shafts are supported in large; ball bearings at their inner\ ends and on Hyatt roller bearings close to the,rear wheels,

By removing the rear wheels,and unbolting the set screws cif the axle tubes, the whole-worm, wheel and differential assembly can be/withdrawn.

Ignition is of the usual Ford type, the current being supplied by a flywheel dynamo.

The front axle is a straight forging which is centrally pivoted to the fiont end of the engine unit.

By unbeltingwthe rear half of the tractor from the engine and removing the eight set screws holdingathe transmission 'plate, this plate, together with the secondary gear shaft, may be withdrawn in oneunit.

The Fordson is fitted with a. paraffin vaporizer, but for starting petrol is used. The paraffin tank 'holds 21 gallons, and the small starting tank half a• gallon of petrol. The radiator with its top tank has a capacity for 11 gallons of water,:which should be ample for the size.of engine ; incidentally, the cooling is on the thermo-syphon principle. At normal engine speed the. gearing gives a speed of 1 m.p.h. on low, 21.1m.p.h. on the intermediate (ploughing speed), and 6.1 m.p.h. on high ; the reverse gives 2i m.p.h.

A neat method is employed for tensioning the fan belt, the fan spindle being -mounted in eccentric washers.

The correct plough to use .with the Fordson is the self-lifting two-furrow type, and it will pull in the heaviest, soil two 14-in, bottoms, but of course, the size to use depends upon the actual conditions under which it is going to work. The tractor must be able to do the work in ploughing gear, as it is not economical to plough continuously in low gear. By using the self-lifting plough, the driver can operate both the tractor and the plough from the tractor seat, as all operating levers are within easy reach. The twowheel tractor plough is attached without the use of chains, and can be backed when necessary.

For stationary work a pulley is fitted on the right side of the tractor and is operated from the engine

clutch. 22 h.p. is, available at the pulley and its normal speed is 1,000 r.p.m. The engine will maintain a drawbar pull of 1,800 lb. at ploughing speed ; in low gear the drawbar pull is 2;500 lb. • A governor is, of course, provided in conjunction with this pulley, the outfit as a whole being supplied-as an extra.

In order to prevent the entry of dust into the mixture the air supply to the Vaporizer is drawn through water.