SPRINGING, SHI AND I

Page 16

Page 17

Page 18

Page 19

If you've noticed an error in this article please click here to report it so we can fix it.

K ABSORPTION

4PING.

WHAT a lot of misnomers there are in the automobile engineer's dictionary ! Such a sentence as this, for instance, "If a spring be a shock absorber, what is a damper?" appears On the face of things to be wrongly worded. Closer examination of the functions of springs7shoek absorbers, and spring dampers will show that a spring is really a shock absorber, whilst a damper, which is usually known as a shock

absorber, is nothing other than a means for introducing friction into the suspension system. Many engineers have made determined and fairly successful efforts to produce special. forms of suspension which will avoid the deficiencies of the present systems. So far, however, we seem to be no nearer uni versal adoption of anything unorthodox in design, as there are so many features outside the problem of suspension which have a bear ing upon the subject in question. Steering, for instance, is very closely inter-connected with the layout of the front axle and its Springs, whilst the suitability of certain classes of metals for any particular work is

a matter which largely, controls the bulk and

weight and, indeed, the whole design of components used in the suspension of a vehicle.

We seem to have wandered a little from the title heading, but a brief review of the poSsibilities, or rather the lack of them, has been deemed necessary before proceeding to define the functions of various members of the springing group.

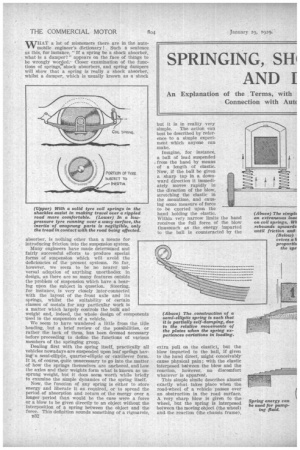

Dealing first with the spring itself, practically all vehicles nowadays are suspended upon leaf springs having a semi-elliptic, quarter-elliptic or cantilever form. It is, of course, quite unnecessary to go into the matter ofhow the springs themselves are anchored, and how the axles and their weights form what is known as unsprung weight, but it does seem worth while briefly to examine the simple dynamics of the spring itself.

Now, the function of any spring is either to store energy and liberate it as required, or to spread the period of absorption and return of the energy over a longer period than would be the case were a force or a blow to he given directly to an object without the interposition of a spring between the object and the force. This definition sounds something of a rigmarole, B32 but it is in reality very simple. The action can best be described by reference to a simple experiment which anyone can make.

Imagine, for instance, a baIl of lead suspended from the hand by means of a length of elastic. Now, if the ball be given a sharp tap in a downward direction it immediately moves rapidly in the direction of the blow, stretching the elastic in the meantime, and causing some measure of force to be exerted upon the hand holding the elastic. '

Within very narrow limits the hand receives the full force of the blow (inasmuch as the energy imparted to the ball is counteracted by the extra pull on the elastic), but the blow imparted to the ball, if given to the band direct, might conceivably cause physical pain ; with the elastic interposed between the blow and the reaction, however, no discomfort whatever is apparent.

This simple simile describes almost exactly what takes place when the road-wheel of a vehicle passes over an obstruction in the road surface. A very sharp blow is given to the wheel, but the spring is interposed between the moving object (the wheel) and the reaction (the chassis frame),

the spring, of course, being equivalent to the elastib portion of our simple example.

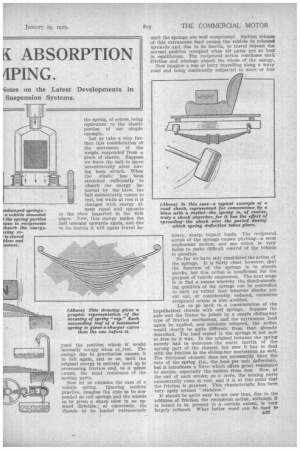

Let us take a step farther this consideration of the movement of the Weight suspended from a piece of elastic. Suppose we leave the ball to move unrestrictedly after having been struck. When the elastic has been stretched sufficiently to absorb the energy imparted by the blow, the hall momentarily comes to rest, bii while at rest it is charged with energy al-. most equal and opposite to the blow imparted in the firSt place. Now, this energy makes the ball rebound upwards again, and due to its inertia it will againtravel be

yond the position which it would normally occupy when at. rest. The energy due to gravitation causes it to fall again, and so on, until the original energy is entirely used up in overcoming friction and, to a minor (-xtent, the wind resistance of the moving parts.

Now let us examine the case of a vehicle spring. Ignoring modern practice, imagine the axle to be suspended on coil springs and the wheels to be given a sharp blow in an upward direction; or conversely, the chassis to be loaded extraneously until the springs are well compressed. Sudden release of thin extraneous load causes the vehicle to rebound upwards and, due to its inertia, to travel beyond the normal position occupied when all parts are at `rest in equilibrium. The reciprocal action continues until friction and windage absorb the whole of the energy.

Now imagine a bus or lorry travelling along a wavy road and being continually subjected to more or less heavy, sharp, impact loads. The reciprocal action of the springs causes pitching—a most unpleasant motion, and one which is very liable to make difficult control of the vehicle in question.

So far we have only considered the action of the springs. It is fairly clear, however, that the function of the springs is to absorb shocks, but this action is insufficient for the purpose of vehicle suspension. The next stage is to find a means whereby the shock-absorbing qualities of the springs can he controlled to such an extent that whereas shocks are cut out, or considerably reduced, excessive reciprocal action is also avoided.

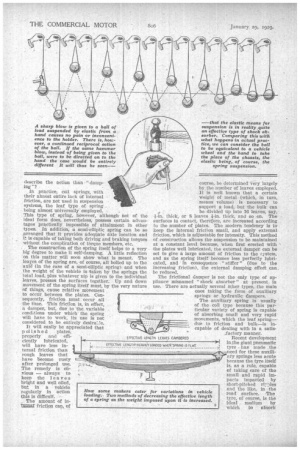

Let us go back to a consideration of the hypothetical chassis with coil springs.. Suppose the axle and the frame be joined by a simple sliding-bar type of friction mechanism, and the extraneous load again be applied, and suddenly released, the action would clearly be quite different from that already described. The load stored in the springs is not now so _free as it was. In the original instance the spring merely had to overcome the static inertia of the sprung part of the chassis, but now it has to deal with the friction in the sliding-bar mechanism as well. The frictional element does not necessarily alter the rate of the spring (i.e., the load per unit deflection), but it introduces a force which offers great resistance to motion, especially the motion from rest. Now, at the end of each stroke, as it weTe, the moving parts momentarily come to rest, and it is at this point that the friction is greatest. This characteristic has been very aptly termed " sticktion."

It should be quite easy to see now that, due to the addition of friction, the reciprocal -action, although It is bound to be present to a certain extent, is very largely reduced. What better word can be used to describe the action than "-damping'?

in practice, coil springs, with their almost entire lack of internal friction, are not used -in suspension systems, the leaf type of spring _ being almost universally' employed. •

This type of spring, however, although not of the ideal form (Ides, nevertheless, possess certain advantages practically impossible of attainment in other types. In addition, a semi-elliptic spring can be so arranged that it provides adequate axle location and it is capable of taking both driving and braking torques without the complication of torque members, etc. , The construction of the spring itself helps to a very big degree to make it self-damping: A little reflection on this matter will soon show what is meant. The leakes of the spring are, of course, all bolted up to the axle (in the case of a semi-elliptic spring) and when the weight of the vehicle is taken by the springs the total load, plus whatever nip is given to the individual leaves, presses the surfaces together.Up and down movement of the spring itself must, by the very nature of things, cause relative Movement to occur between the plates. COnsequently, friction must occur all the time. This friction is, in effect, a damper, but, due to the variable conditions under which the spring Will have to work, its use is not considered to be entirely desira:„le.

It Will easily be appreciated that

polished plates, properly and are cientIy lubricated, will have less internal friction than rough leaves that have become rusty . ----after prolonged use.

The remedy is ob vious — always to

keen the leaves bright and well oiled,

but in a vehicle regularly in action this is difficult. .,. The amount of hi=DU friction can, of

course, be determined very largely by .the number of leaves employed. It is well known that a certain weight of metal (which, in turn, -means volume) is necessary to support a load, but the bulk can • be divided up into 16 leaves, say, i•in. thick, or S leaves Fin, thick, and so on. The surfaces in contact, therefore, are increased according to the number of plates. The modern tendency is to keep the internal friction small, and apply external friction, which is adjustable for intensity. This method of construction allows the suspension to be maintained at a constant level because, wheu first erected with the plates well lubricated, the external damper can be set to give a large amount of friction to the system, and as the spring itself becomes less perfectly lubricated,, and in consequence " stiffer " (due to the increasing friction), the external damping effect can be reduced.

The frictional damper is not the only type of appliance misnamed "shock absorber" at present, in use. There are actually several other types, the main ones taking the form of auxiliary springs or hydraulic dampers.

The auxiliary spring is usually • of the coil type because this particular variety of spring is capable of absorbing small and very rapid movements, which the leaf spring— due to friction and bulk—is incapable of dealing with in a satis factory manner.

Recent development in the giant pneumatic tyre • has made the ...need for these auxiliary springs less acute because the tyre itself is, as a rule, capable of taking care of the small and rapid impacts imparted by short-pitched rirnles and the like, in the road surface. The tyre, of course, is the ideal medium by which to absorb'

shocks, because the inertia of the moving parts is extremely small. Actually, in so far as the tyre itself as a separate component is concerned, the unsprung mass consists of the small portion of tread in contact with , the road surface, Which portion, of course, moves in relation with the rest of the tyre. The weight of this small portion is clearly negligible.

We next come to a consideration of the hydraulic damper. In reality this type is more of a shock absorber than a frictional damper, although fluid friction is employed. There are . many types of damper at present on the market using the hydraulic principle, most of which work with great satisfaction. In nearly all the hydraulic systems the damping effect is produced by making the movement of the axle pump fluid through a restricted orifice, which, of course, introduces a time element. Un

fortunately, however, this time clement occurs on both small and large amplitudes of spring movement. It will be appreciated that a leak through a hole, when a spring makes a movement of, say, 1 in., is considerably smaller than when the movement is in the neighbourhood of 6 ins., consequently a pressure-release` valve has to be provided. This valve, of course, keeps the resistance to motion fairly constant, instead of increasing it as the amplitude increases.

We have not been able to deal with every phase of the three problems owing to the limitation imposed by the space at our disposal, but perhaps, however, we have given enough information to permit those of our readers who were not well versed in this subject something upon which they can base their ideas as to what is required in the development of an ideal system of suspension for commercial vehicles.