Trucks replace Swedish river transport of timber fast

Page 34

Page 35

Page 36

If you've noticed an error in this article please click here to report it so we can fix it.

by Eric Gibbins, MCIT

TWENTY YEARS AGO the normal method of transporting timber in Sweden was to float it down the rivers. Over the past two decades, however, co-ordinated truck and rail transport has moved into the picture so that the Swedish equivalent of the Road Haulage Association reckons that in another 10 to 15 years flotation will have ceased completely. Of the yearly timber cut, which is as much as 1560m cu ft, 170m cu ft was floated in 1970 and 198m travelled by rail. The remainder was carried by truck direct from forest to industry.

One of the key areas for production is around Sundsvall, 400 kilometres north of Stockholm on the Baltic coast. In this region 100m cu ft of timber is cut annually by the biggest producer, Svenska Cellulosa Aktiebolaget (SCA for short).

100km hauls

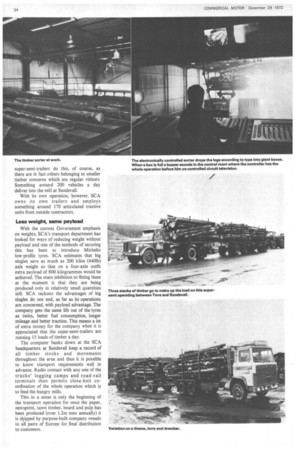

For this company road transport is used to move logs on hauls of up to 100km direct from the forest cutting area to the Tova timber terminal just outside Sundsvall. Train loads of timber also run regularly every day into Tova from the regions more than 100 kilometres from the terminal. Road transport from the cutting areas again feed these.

There are six outlying rail terminals of this kind serving the mills in the Sundsvall region. The Sundsvall area has seven pulp, paper and saw mills (three of them pulp, two paper, two saw). These consume something like 3.3m tons of timber a year and it is the job of the SCA transport department to supply it as it is consumed. Except for one sawmill, storage space is negligible so it is an around the clock operation to supply the mills concerned.

One train a day runs in from each of the seven road-rail stations, each comprising 43 railway wagons carrying 1200 tons of timber. As it arrives at Tova unsorted it has to be sorted into timber categories; pine, spruce, birch and so on. It is sorted in a massive computer controlled, electronically operated machine at the end of which the timber drops down into boxcars for transfer by log-handling trucks to the waiting road vehicles. Many of these are what the Americans would call double-bottoms. They are articulated vehicles hauling semi-trailers, but there are a number of variations through the extensive use of dollies.

However, the operation starts in the forests and there, as throughout the whole of the SCA, operational control is by direct radio link to every driver engaged on the work. Radio control is found to be invaluable because if a driver reports that the weather is bad in his area such that pick-up is well nigh impossible he can be diverted to another location with comparative ease.

The only roads in many of these areas are those built for timber operations. A large number of ordinary semi-trailers operating at up to 38 tons gew handle this work. They carry the loads either to the railhead where it is weighed over a weighbridge and unloaded ready for stacking correctly on to the railway wagons or it is shifted direct to the Tova terminal depending on whether or not the 100km rule applies.

Clamp down on weights A feature of the vehicles used for the run from Tova to Sundsvall is that chains are employed to secure the load but these are toggle-linked to wires, which run permanently through the cross-members of the chassis and are connected to airpipe circuitry so that they can be drawn tight over the load by pneumatic power supplied from the tractive unit. Batch loading at the terminal permits fairly good load control and this is becoming particularly important in Sweden, as it is everywhere else, because the Government has clamped down on the enormous outfits which, until relatively recently, were permitted. As in Britain there is concern over bridge weight limits so that now the effective weight of outfits is largely down to 38 tons compared with the 45 tons formerly permitted. One of the main problems is that low winter temperatures reduce the strength of bridges but raise the carrying capacity of the roads which can be frozen to a depth of 7ft.

Pulp mills down on the coast never have more than 10 hours stock of timber at a time so the transport movement operates five days a week on a three-shift working basis to feed the mills. Not just the SCA super-semi-trailers do this, of course, as there are in fact pthers belonging to smaller timber concerns which are regular visitors. Something around 200 vehicles a day deliver into the mill at Sundsvall.

With its own operation, however, SCA owns its own trailers and employs something around 170 articulated tractive units from outside contractors.

Less weight, same payload

With the current Government emphasis on weights, SC A's transport department has looked for ways of reducing weight without payload and one of the methods of securing this has been to introduce Michelin low-profile tyres. SCA estimates that big singles save as much as 200 kilos (440Ib) axle weight so that on a four-axle outfit extra payload of 800 kilogrammes would be achieved. The main inhibition to fitting them at the moment is that they are being produced only in relatively small quantities still. SCA reckons the advantages of big singles do not end, as far as its operations are concerned, with payload advantage. The company gets the same life out of the tyres as twins, better fuel consumption, longer mileage and better traction. This means a lot of extra money for the company when it is appreciated that the super-semi-trailers are running 15 loads of timber a day.

The computer banks down at the SCA headquarters at Sundsvall keep a record of all timber stocks and movements throughout the area and thus it is possible to know transport requirements well in advance. Radio contact with any one of the trucks' logging camps and road-rail terminals then permits close-knit coordination of the whole operation which is to feed the hungry mills.

This in a sense is only the beginning of the transport operation for once the paper, newsprint, sawn timber, board and pulp has been produced (over 1.2m tons annually) it is shipped by purpose-built company vessels to all parts of Europe for final distribution to customers.