Coming clean on plating and testing

Page 32

Page 33

If you've noticed an error in this article please click here to report it so we can fix it.

by Johnny Johnson

THE SUBJECT of plating and testing local authority vehicles came up when I was speaking to the manager of a Department of the Environment testing station recently. He told me that local councils had little difficulty in getting the vehicles, which they sent, passed without defects. But the emphasis was on the phrase "which they sent".

Intrigued, I asked him why he had made this reservation. He told me that his impression was that councils were submitting only their newer vehicles. Those which did not have comparatively new vehicles seemed to be making little effort to have their fleet plated and tested.

The reason for this attitude is not difficult to discover. Councils have until September 1973 to complete vehicle plating and testing. In the meantime, the proposals for revising the local authority boundaries are being finalized. Those councils which are likely to disappear under the new boundary proposals are reluctant to incur expense or perhaps reveal the inadequacy of their maintenance arrangements by having their vehicles examined. After all, when the new boundaries are finally redrawn, plating and testing will become someone else's headache.

While this might he the explanation for the slow rate of vehicle testing by councils, in many cases it is not the whole story. All council fleet engineers are inhibited by the annual budget of the particular local authority by which they are employed.

It is not reasonable to expect any operator to go to the trouble of plating and testing a vehicle which is scheduled for replacement. There are, no doubt, many council engineers who are now wondering if their authority will sanction in full their vehicle replacement programmes before they are compelled to spend money on preparing elderly vehicles for testing.

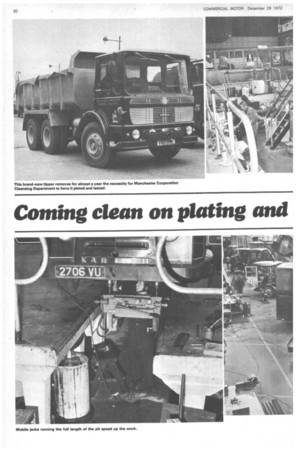

To find out how this problem was being tackled, I went to Manchester where Mr Oliver Grange, the Cleansing Department's chief engineer, has over 230 vehicles in his charge of which about 150 are subject to the plating and testing regulations.

The corporation has set up an extensive workshop in the former locomotive works of Beyer Peacock at Gorton. It is from this workshop that the maintenance of the fleet is controlled.

Each vehicle is examined thoroughly every three weeks. This is necessary because most of the vehicles are required to go on refuse tips and so are subject to somewhat rough treatment. The stringency of the examination is increased at nine-weekly intervals.

At the 45th-week periodic examination, preparations are begun for testing. These progress through the various stages according to the condition of the vehicles at the 48th and 51st-week periods. At the last examination, steam cleaning and final preparation for the visit to the testing station are undertaken.

In adopting this system, Mr Grange has ensured that there is a period of some seven weeks in which to correct any fault in the vehicle before submitting it to the vehicle examiners' tender mercy.

Not all the maintenance work is done at the Gorton shop. There is a fitter at each of the five satellite cleansing depots throughout the city. A weekly workshop maintenance programme is prepared and sent to each of these fitters. It sets out the vehicle to be attended to, the day on which the examination should be made, and the period of the examination due.

Most of the work necessary can be carried out at the depot concerned and a vehicle inspection record, which details the inspection made and repairs effected, certified by the fitter and filed. Anything which cannot be rectified at the out-depot is programmed into the Gorton workshop.

This is a spacious well-equipped building which is being extended to increase its capacity following a proposal that other departments' vehicles should be maintained there. It has a paint shop, a body shop, separate bays for each trade, and an extensive stores security area.

At one end, three pits have been provided, each of which is equipped with a mobile jack that moves along a runway at each side of the pit. Alongside the pits there is a rolling-road brake tester.

An electric illuminated indicator is placed high in front of the driver of the vehicle being tested. Using this, instructions can be given to the driver so that the possibility of mistakes arising from misheard verbal instruction is eliminated.

Other equipment includes a number of fixed vehicle-lifting jacks and trolley jacks.

Mr Grange told me that a dozen or so vehicles had already been plated and tested since the Regulation was extended to council vehicles last March. The pace was now increasing, however, and the arrangements made, together with the replacement programme, should see the majority of vehicles dealt with by the September deadline.

Despite the doubts expressed by my friend from the DoE, I am convinced that most council engineers are doing their best to comply, as indeed they must. As for those awaiting the outcome of the local authority boundary revision, some of them might find themselves committed to a last-minute scramble though I am of the opinion that only a few vehicles will be involved.

It should be remembered, however, that the go-slow being operated at Ministry testing stations, particularly in the North, which is making things difficult for even the willing councils such as Manchester, will make things even more difficult for the laggards in the long run.