Chassis dyno saves fuel

Page 41

Page 42

If you've noticed an error in this article please click here to report it so we can fix it.

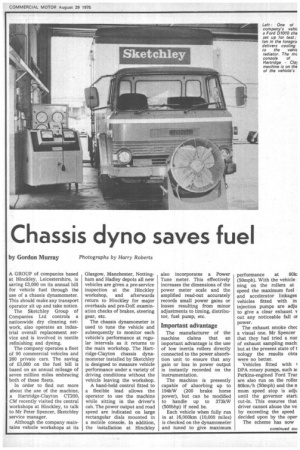

by Gordon Murray Photographs by Harry Roberts A GROUP of companies based at Hinckley, Leicestershire, is saving £3,000 on its annual bill for vehicle fuel through the use of a chassis dynamometer. This should make any transport operator sit up and take notice.

The Sketchley Group of Companies Ltd controls a nationwide dry cleaning network, also operates an industrial overall replacement service and is involved in textile refinishing and dyeing.

The company operates a fleet of 90 commercial vehicles and 260 private cars. The saving of £3,000 on the fuel bill is based on an annual mileage of seven million miles embracing both of these fleets.

In order to find out more about the use of the machine, a Hartridge-Clayton CT200, CM recently visited the central workshops at Hinckley, to talk to Mr Peter Spencer, Sketchley service manager.

Although the company maintains vehicle workshops at its Glasgow, Manchester, Nottingham and Hadley depots all new vehicles are given a pre-service inspection at the Hinckley workshop, and afterwards return to Hinckley for major overhauls and pre-DoE examination checks of brakes, steering gear, etc.

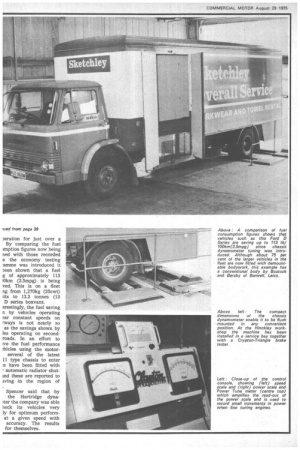

The chassis dynamometer is used to tune the vehicle and subsequently to monitor each vehicle's performance at regular intervals as it returns to the main workshop. The Hartridge-Clayton chassis dynamometer installed by Sketchley is designed to measure vehicle performance under a variety of driving conditions without the vehicle leaving the workshop.

A hand-held control fitted to a flexible lead allows the operator to use the machine while sitting in the driver's cab. The power output and road speed are indicated on large rectangular dials mounted in a mobile console. In addition, the installation at Hinckley also incorporates a Power Tune meter. This effectively increases the dimensions of the power meter scale and the amplified read-out accurately records small power gains or losses resulting from minor adjustments to timing, distributor, fuel pump, etc.

Important advantage

The manufacturer of the machine claims that an important advantage is the use of low inertia rollers directly connected to the power absorbtion unit to ensure that any gain or loss in power output is instantly recorded on the instrumentation.

The machine is presently capable of absorbing up to 194kW (200 brake horse power), but can be modified to handle up to 373kW (500bhp) if need be.

Each vehicle when fully run in at 16,000km (10,000 miles) is checked on the dynamometer and tuned to give maximum performance at 8010 (50mph). With the vehicle• fling on the rollers at speed the maximum fuel and accelerator linkages vehicles fitted with in injection pumps are adju to give a clear exhaust out any noticeable fall col power.

The exhaust smoke chec a visual one. Mr Spencer that they had tried a nur of exhaust sampling mach: but at the present state of t nology the results obta were no better.

Vehicles fitted with DPA rotary pumps, such at Perkins-engined Ford Trar are also run on the rollet 80km/h (50mph) and the n mum speed stop is adju until the governor start! cut-in. This ensures that driver cannot abuse the ye by exceeding the speed decided upon by the oper The scheme has now peration for just over a By comparing the fuel imption figures now being ned with those recorded e the economy testing .amme was introduced it Deen shown that a fuel g of approximately 113 10km (2.5mpg) is being ved. This is on a fleet rig from 1,270kg (25cwt) its to 13.2 tonnes (13 D series boxvans.

erestingly, the fuel saving n by vehicles operating aar constant speeds on -ways is not nearly so as the savings shown by [es operating on secondroads. In an effort to we the fuel performance !hides using the motorseveral of the latest 11 type chassis to enter ;e have been fitted with automatic radiator shutand these are reported to wing 'in the region of Spencer said that -by the Hartridge dynaqer the company was able neck its vehicles very ly for optimum performat a given speed with accuracy. The results for themselves.