An Epicyclic Gear Desigr for Automatic Control

Page 40

Page 41

If you've noticed an error in this article please click here to report it so we can fix it.

The Fleischel Unit in Which Changes Can Be Made, by Automatic Means, Without Interruption of Driving Torque. Four Forward Ratios Provided by Two

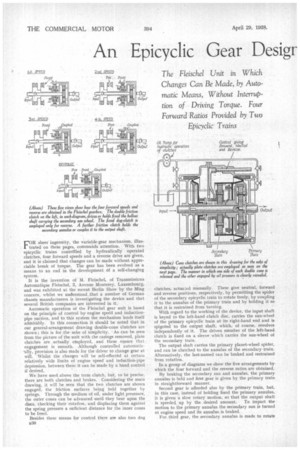

(Above) These five views show how the four forward speeds and reverse are obtained in the Fleischel gearbox. The double friction clutch on the left, in each diagram, drives or holds fixed the hollow shaft carrying the secondary sun wheel. The fixed dog-clutch is employed only for reverse. A further friction clutch holds the secondary annulus Or couples a to the output shaft.

COB sheer ingenuity, the variable-gear mechanism, trated on these pages, commands attention.. With two epicyclic trains contralled by hydraulically operated clutches, four forward speeds and a reverse drive are given, and it is claimed that changes can be made without appreciable break of torque. The gear has been evolved as a means to an end in the development of a self-changing system.

It is the invention of M. Fleischel, of Transmissions Automatique Fleischel, 3, Avenue Monterey, Luxembourg, and was exhibited at the recent Berlin Show by the Miag concern, whilst we understand that a number of German chassis manufacturers is investigating the device and that several British companies are interested in it.

Automatic operation of the Fleischel gear unit is based on the principle of control by, engine speed and inductionpipe suction, and to this system the mechanism lends itself admirably. In this connection it should be noted that in our general-arrangement drawing double-cone clutches are shown; this is for the sake of simplicity. -.As can be seen from the picture of the unit with the casings removed, plate clutches are actually employed, and these ensure that engagement is smooth. Although controlled automatic'illy, provision is' also made for the driver to change gear at will. Whilst the changes will be self-effected at certain relatively wide limits of engine speed and induction-pipe depression, between these it can be made by a hand control if desired.

We have used above the term clutch, but, to be precise, there are both clutches and brakes. Considering the main drawing, it will be seen that the two clutches are shown engaged, the friction surfaces being held together by springs. Through the medium of oil, under light presssure, the outer cones can be advanced until they bear upon the discs, checking their rotation, and displacing them against the spring pressure a sufficient distance for the inner cones to be freed, Besides these means for control there are also two dog B30 clutches, actuated manually. These give neutral, forward and reverse positions, respectively, by permitting the spider of the secondary epicyclic train to rotate freely, by coupling it to the annulus of the primary train and by holding it so that it is restrained from turning.

With regard to the working of the device, the input shaft is keyed to the left-hand clutch disc, carries the sun-wheel of the primary epicyclic train at its right-hand end and is spigoted to the output shaft, which, of course, revolves independently of it. The driven member of the left-hand clutch is fixed on a sleeve which carries the sun-wheel of the secondary train.

The output shaft carries the primary planet-wheel spider, and can be Clutched to the annulus of the secondary train. Alternatively, the last-named can be braked and restrained from rotation.

In a group of diagrams we show the five arrangements by which the four forward and the reverse ratios are obtained.

By braking the secondary sun and annulus, the primary annulus is held and first gear is given by the primary train in straightforward manner.

Second gear is afforded also by the primary train, but, in this case, instead of holding fixed the primary annulus. it is given a slow rotary motion, so that the output shaft is speeded, up by the desired amount. To impart the motion to the primary annulus the secondary sun is turned at engine speed and its annulus is braked.

For third gear, the secondary annulus is made to rotate at the same speed as the output shaft, and this has the effect of revolving the secondary planets about their sun wheel, which is fixed. They rotate the secondary spider and with it the primary annulus, thus imparting to the primary planets, together with their spider, a speed of revolution about the main axis still higher than before.

Fourth speed is direct, the two sun wheels being clutched and turning together, and the primary spider being coupled to the secondary annulus, thus locking both trains.

Shifting the secondary planet assembly to the left has the effect of holding the spider, so that rotation of the sun causes reverse rotation' of the annulus. This is transmitted directly, via the primary clutch and spider, to the output shaft.

There seems little need to draw attention to the simplicity with which the various changes in the forward range are made. For each clutch a single short travel, requiring oil at a pressure of only five atmospheres is all that is needed.

In our picture of an engine and gear unit, the pump and oil distributor are seen at the front of the engine and the pipes can be traced back to the gearbox. The remaining view shows the gear mechanism with the casing removed, and the plates of the clutches and brakes, together with one set of springs, axe clearly discernible. In view of the popularity and efficiency of the type of gearbox, in which toothed wheels are employed, this new device would seem to have good prospects, because it combines, in a measure, ):he attractions of the commonly used system with the ease, simplicity of control and freedom from interruption of drive of the electric, hydraulic, pendulum or other form of torque converter, and thus approaches nearer to the ideal.