The End of an Era?

Page 80

Page 81

Page 82

Page 83

Page 84

Page 85

Page 86

Page 87

Page 88

If you've noticed an error in this article please click here to report it so we can fix it.

By JOHN F. MOON

A.M.I.R.T.E.

THIS year's Commercial Motor Show could well be the last to be held with Britain as a non-member of the European Economic Community, so this may be the last chance that visitors to the London Show will have of seeing uninfluenced British designs. Assuming that Britain will join the Common Market, the 1964 Show will obviously contain a large number of designs intended to meet the Proposed European vehicle-construction regulations—proposals which could well see the end of the rigid eight-wheeler. The next two years, therefore, could see a complete change of design viewpoint, in the light of which a review of technical progress such as this could also be taken as an obituary of some 60 years of commercial-vehicle design thought.

Fortunately, there are no signs that this possibility is depressing our British manufacturers: fairly rapid changes in legisation have been accommodated before without undue alarm—even though these have only been with respect to the United Kingdom! However, it is obvious that our vehicle designers are alive to the possible effects of our joining the Common Mark. and are accordingly getting prepared for this eventuality. C the score of basic vehicle design alone, I am confident that th British industry will be able to compete With their Continent contemporaries: the test will be whether the quality of oi vehicles can be brought up to the same standard as that European manufacturers. Intensive competition should hal the effect of improving quality, so far as British producers a. concerned.

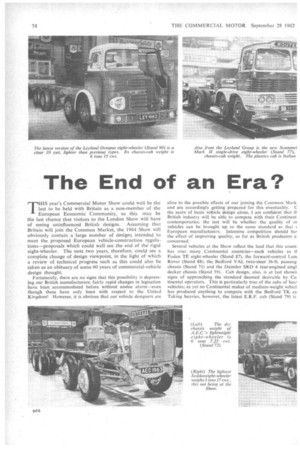

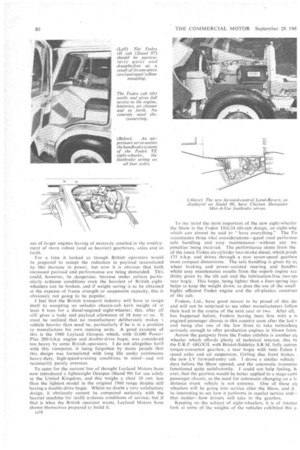

Several vehicles at the Show reflect the lead that this count] has over, many Continental countries—such vehicles as tl Foden TE eight-wheeler (Stand 87), the forward-control Lam Rover (Stand 88), the Bedford VAL twin-steer 36-ft. passeng, chassis (Stand 70 and the Daimler SRD 6 rear-engined singI decker chassis (Stand 59). Cab design, also, is at last showit signs of approaching the standard deemed desirable by Co tinental operators. This is particularly true of the cabs of hew vehicles; as yet no Continental maker of medium-weight vehicl has produced anything to compare with the Bedford TK ca Taking heavies, however, the latest E.R.F. cab (Stand 79) is tch for anything built in production quantities in Europe, ilst the Foden tilt cab has no equivalent this side of the antic; it forms part of one of the most subtly advanced ivy vehicles to have been developed in this country for many ear.

laken generally, design changes since the 1960 Show have been spectacular, despite the large number of new vehicles libited in Earls Court. Four years ago, for example, there re signs that disc brakes and air suspension were about to be ipted as standard equipment by various manufacturers. Two rs ago the signs were less obvious, and now they are almost 1-existent. The story of turbocharging follows a similar tern, whilst fully automatic transmissions (such as those based the original Wilson epicyclic gearbox) do not currently seem

to be regarded with the same favour that they were a few years ago, although semi-automatic versions are popular on passenger chassis.

The reaction of operators cannot necessarily be blamed for this apparent lack of progress, for fleet engineers have often reported favourably on service experience with the types of equipment just referred to. Cautiousness on the part of British vehicle manufacturers has mainly been responsible for the slow adoption of such technical innovations, so all credit to the people concerned for adopting this attitude. Particularly overseas, a manufacturer's reputation can plummet overnight if a conventional piece of equipment should prove faulty, and the chances of this occurring with relatively untried products are considerably greater.

What are the obvious trends this year, therefore? So far as goods vehicles are concerned there has been a welcome turn to providing better chassis and body layouts for delivery vehicles and, in the heavy field, towards reducing unladen weight. Passenger-vehicle design has obviously been influenced by the British regulations introduced last year which permit buses and coaches of up to 36 ft. overall length. Whilst this has not resulted in any greatly changed chassis coming from the wellestablished heavy-vehicle manufacturers such as A.E.C. and Leyland, it has produced the quite striking Bedford and Daimler single-decker designs.

It is difficult to say exactly where heavy goods vehicle design will lead to, partly because of the impending Common Market regulations which, if adopted, will restrict all rigid goods vehicles to a gross weight of 22 metr:c tons. The weight-saving process which has been so marked over the past few months is obviously a repercussion from the noticeable increase in powerto-weight ratios which took place three or four years ago, the use of larger engines having of necessity resulted in the employment of more robust (and so heavier) gearboxes, axles and so forth.

For a time it looked as though BritishE operators would he prepared to accept the reduction in payload necessitated by this increase in power, but now it is obvious that both increased payload and performance are being demanded. This could, however, be dangerous, because under certain particularly arduous conditions even the heaviest of British eightwheelers can be broken, and if weight saving is to be obtained at the expense of frame strength or suspension capacity, this is obviously not going to be popular.

I feel that the British transport industry will have to resign itself to accepting an unladen chassis-cab kerb weight of at least 6 tons for a diesel-engined eight-wheeler; this, after all still gives a body and payload allowance of 18 tons or so. It must be realized that no manufacturer deliberately makes 't vehicle heavier than need be, particularly if he is in a position to manufacture his own running units. A good example of this is the 1960 Leyland Octopus which, with 0.680 PowerPlus 200-b.h.p. engine and double-drive bogie, was considered too heavy by some British operators. I do not altogether hold with this viewpoint, it being forgotten by many people that this design was formulated with long life under continuous heavy-duty, high-speed-cruising conditions in mind—and not necessarily purely overseas.

To cater for the current line of thought Leyland Motors have now introduced a lightweight Octopus (Stand 90) for use solely in the United Kingdom, and this weighs a clear 10 cwt. less than the lightest model in the original 1960 range despite still having a double-drive bogie. Whilst no doubt a very satisfactory design, it crbviously cannot be compared seriously with the heavier machine for reallY arduous conditions of service; but if that is what the British operator wants, Leyland Motors have shown themselves prepared to build it.

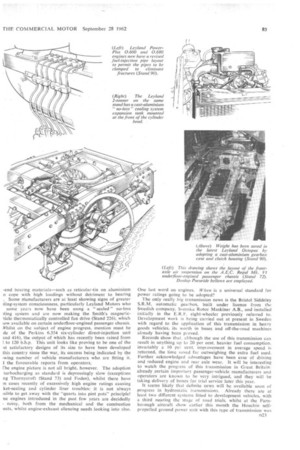

Dlg

To my mind the most important of the new eight-wheeler the Show is the Foden TE6/24 tilt-cab design, an eight-whe which can almost be said to " have everything." The Fo accentuates three vital considerations—good road performat safe handling and easy maintenance—without any we penalties being incurred. The performance stems from the of the latest Foden six-cylinder two-stroke diesel, which prodh 175 b.h.p. and drives through a new seven-speed gearbox most compact dimensions. The safe handling is given by eij wheel braking and power-assisted steering and handbrk whilst easy maintenance results from the superb engine ace ibility given by the tilt cab and the lubrication-free two-spi rear bogie. This bogie, being lighter than a four-spring lay, helps to keep the weight down, as does the use of the small highly efficient Foden engine and the all-plastics construct of the cab.

Fodens, Ltd., have good reason to be proud of this des and will not be surprised to see other manufacturers follovt their lead in the course of the next year or two. After all, has happened before, Fodens having been first with a n engined passenger chassis in this country soon after the last v and being also one of the few firms to take turbocharg seriously enough to offer production engines in blown form.

Across the gangway from the Foden exhibits is another cit wheeler which affords plenty of technical interest, this bc the E.R.F. 68GX3L with Bristol-Siddeley S.R.M. fully autom torque-convertor gearbox, a rear bogie with twin Eaton t speed axles and air suspension, Girling disc front brakes the new LV forward-entry cab. I drove a similar vehicle ' days before the Show opened, and the automatic transrniss functioned quite satisfactorily. I could not help feeling, hi ever, that the gearbox would be better applied to a stage-earni passenger chassis, as the need for automatic changing on a lc distance trunk vehicle is not extreme. One of these eU wheelers will be going into service after the Show, and it be interesting to see how it performs in regular service and— that matter—hoW drivers will take to the gearbox.

Keeping on the subject of eight-wheelers, it is of interest look at some of the weights of the vehicles exhibited this yi

The A.E.C. Mammoth Major Mk. V (Stand 72) has a quoted ry weight, without cab, of 6 tons 7.25 cwt., a saving of just ter 5 cwt. compared with the lightest model previously offered y this company. Weight saving has mainly resulted from nploying a lighter driving axle and Girling cam brakes.

The Atkinson Weightmaster eight-wheeler (Stands 101 and )4) shows an even greater reduction in weight over earlier tkinson designs, the standard chassis—which has a Gardner LW engine and Eaton two-speed axle—weighing 5 tons 15 cwt. t chassis-cab form. Much of this weight has been saved at le rear bogie itself, but the use of 9.25-in.-deep chassis side [embers and narrower front and rear springs has helped conderably also. The automatic-gearbox E.R.F. has a dry tassis-cab weight of 6 tons 6 cwt., whilst the Foden TE weighs tons 4 cwt. as a chassis-cab ready for the road, its dry weight !ing 5 tons 17 cwt.

A dry chassis-cab weight of 5 tons 19 cwt. is quoted for the test Guy Warrior Light 8 eight-wheeler with Gardner 6LW tgine, this, like the Weightmaster, having a single-drive bogie ith Eaton two-speed axle also (Stand 58). The lightweight eyland Octopus weighs 6 tons 15 cwt., whilst the new :ammell Routeman Mark II (Stand 77) has a dry chassistb weight of exactly 6 tons. The kerb weight of Seddon's ghtest eight-wheeler (Stand 93) is 5 tons 17 cwt., the specifiIlion of this being like the Atkinson and the Guy in respect power unit and driving axle. It will be seen, therefore, that weights of 6 tons,or less are being achieved only by using relatively low-powered engines and compensating for this by employing a two-speed axle, this axle being the principal difference between these latest lightweights and eight-wheelers built in this country, say, five years ago. The exception to this rule, of course, is the E.R.F. petrol:engined eight-wheeled chassis (Stand 96) designed primarily for tanker applications and which weighs 5 tons 7 cwt. Weight saving has been carried to extremes in the case of this vehicle, even to the extent of fitting tubeless tyres and so gaining an extra 3 cwt. of payload, but this can be decisive in the case of oil companies, for instance, who prefer to be able to deliver loads of 4,000 gal. (rather than an odd number like 3,650 gal.) as this helps them make full use of punch-card delivery recording. Still, in two yearstime the eight-wheeler might be a thing of the past. We shall see. ,

Turning now to lighter chassis, the delivery-vehicle operator has much to be thankful for this year. The choice in the field of up to 1-ton payload has widened to a welcome degree by the introduction of the Triumph Courier 5-cwt. van (Stand 67) and Morris 10-cwt. (Stand 56) and Standard 15-cwt. and t-ton (Stand 70) vans and pick-ups, the Standard 1-tonner being available with the Standard 2.26-litre diesel engine as optional equipment. The up-rating of the Renault Fstafette (Stand 89) from 12to 15-cwt. has been a move in the right direction also, particularly as it has been accompanied by the employment of a larger engine with a five-bearing crankshaft. The Estafette has a lot to commend it because of its frontwheel drive, which results in a very low unobstructed floor [inc.

Clear access to the driving seat, both from outside the vehicle and from the payload space, has for long been one of the most pressing needs of delivery vehicles in the 1-2-ton range, and this gap is now being filled very satisfactorily by products from Ford, Leyland, Routes and Vauxhall, plus the B,M.C.-H.C.B. model announced two weeks ago but not exhibited at Earls Court. Rootes were the first to tackle this problem seriously, with their Commer Walk-Thru models (Stand 74) introduced last year, and the new Bedford-Hawson Easy-Access design is very similar, as was only inevitable. These manufacturers have shown that unconventional chassis layout need not be resorted to in order to give optimum facilities for the roundsmen, the simple expedient of adopting semi-forward-control being sufficient to keep the engine far enough forward of the driving position. The Ford approach has been slightly different in that thei Garner-bodied 2-ton van (Stand 78) is based on a standari Thames Trader normal-control chassis, whereas the Bedfor, Hawson design uses a normal-con trpl chassis converted to semi forward layout. The B.M.C.-based model makes use of ; standard forward-control FG-type chassis, with possibly no quite the same advantages in respect of access to the drivin; seat from the kerb side of the vehicle. The Leyland 2-tonne has forward-control also; but the engine is beneath the seats so providing no obstruction.

Normal-control for larger vehicles still has its following, a evidenced this year by the introduction of Trader fourant six-cylinder designs of this configuration. All the other high quantity manufacturers continue to produce normal-contre vehicles of up to 5, or even 7, tons capacity, principally becaus of the advantages of increased cab space and improved engin' accessibility. The modern forward-control cab, however, catching up in this respect, even on tightand medium-weigh chassis, a good example of this being the new Commer cab.

These same high-quantity manufacturers continue graduatl; to infiltrate into the field of the established heavy-vehicle makers The latest example is the Bedford TK 8-tonner which, contrar] to recent Bedford practice, makes use of non-Bedford majo units—Leyland engine, Clark gearbox and Eaton axle. A least one other 8-tonner was expected to be introduced for thi

ow; but this has not materialized. Undoubtedly the gap .ween the two classes of manufacturer is rapidly narrowing. kinong the more specialized goods vehicles one of the most portant recent introductions has been the forward-control nd-Rover, which can carry 30 cwt. on normal hard surfaces

d is, therefore, in a class by itself as far as European produc n is concerned. The adoption of forward control has not ,ulted in any appreciable loss of driving amenities compared di the standard normal-control Land-Rovers, but has given :atly increased payload space and improved front-rear axleding distribution, this being now virtually 50-50. Better off:-road performance will result from this, of course, whilst use of 9.00-16 wheels and long spring-hanger brackets e good ground clearance.

Fligher-capacity 4 x 4s are appearing on the market in larger antities every year, many of these incorporating converns by All Wheel Drive, Ltd. (Stand 373) whose work is de use of by Commer, Dodge, Leyland and Ford among iers. 1 have for long been of the opinion that greater use aid be made of 4 x 4 tippers of about 5-ton capacity in s country, and whereas a few years ago there was a valid use that few models of this type were available, this no iger applies. The improved traction given over bad surfaces

result in really valuable increase in efficiency and reduction time wastage.

With the exception of the E.R.F. and Foden eight-wheelers, sssis-design progress generally has been more marked in pect of passenger vehicles this last few months, outstanding Eng the Bedford and Daimler 36-ft. single-decker models, e Bedford VAL front-engined twin-steer six-wheeled chassis s been a real eye-opener for British passenger operators o for years have been used to underfloor-engined single:kers; but the rather unconventional layout of the chassis ; resulted largely from the manufacturer's desire to use as

many standard Bedford goods-chassis components as possible in order to keep the chassis price down. The success of this policy is shown by the VAL'sprice of £1,775, and the use of 16-in, wheels carries big advantages also in respect of low frame height and improved stability.

The Daimler layout could not be more different from that of the Bedford, the engine of this vehicle being mounted horizontally across the rear of the chassis. The Fleetline doubledecker chassis, which has its engine vertically across the rear of the chassis, has formed the basis of the prototype exhibited in Earls Court and the low-height cranked frame of the Flectline gives the new single-decker chassis the advantage of being suitable for bodywork with no steps between the wide entrance platform and the extreme rear of the vehicle. This is particularly valuable for stage-carriage operations as it can speed up loading and unloading. The only slight disadvantage of having such a low stepless central gangway can be the rather

large size of the wheel boxes, particularly at the front. Careful planning of seating layout should, however, minimize this effect.

The entrance ahead of the front wheels has growing appeal for both bus and coach operators, and this had led Dodge (Stand 54) to produce a fairly conventional front-engined passenger chassis with a set-back front axle to permit the provision of a front entrance. This should meet the requirement of rural bus undertakings who are desirous of introducing oneman operation but have hitherto been faced with the comparatively high chassis cost of underfloor-engined designs in order to have an entrance opposite the driving position. That Dodge are not the only ones wth this thought in mind is shown by the Yeates-converted Bedford passenger vehicles (Stand 43), which have a similar layout.

Double-decker operators continue to be something of a headache for our bus-chassis designers as it is still not clear where they consider the entrance should be—immediately ahead of or immediately behind the front wheels, or at the extreme rear. The entrance behind the front wheel seems to be gaining ground, and has led to the A.E.C. Renown and the Albion Lowlander (Stand 76) cranked-frame front-engined designs, both of which are suitable for stepless central gangways. Even the integral A.E.C.-Park Royal Routemaster built for London Transport (Stand 40) has appeared with a forward entrance, whilst the well-known Guy Wulfrunian has been modified specially at the request of Wolverhampton Corporation Transport to make it suitable for a similar entrance location, the chassis changes involved including moving the independently suspended front wheels forward by 2 ft. 8 in.

So much for chassis: there are many interesting applications at the Show which are not mentioned by name but which follow the general trends already indicated in their respect classes. Time now to consider the design state of the vatic mechanical units and items of equipment which go to make these vehicles.

So far as engines are concerned the most distinct trend I been to increase power outputs without increasing the exter engine size. Commonplace examples of this can be seen in case of Bedford, B.M.C. and Perkins diesels, although possi a more outstanding instance is that of the Foden six-cylin■ two-stroke diesel. When this was first introduced back in 1S as a 4.1-litre engine, it was rated to develop 126 b.h.p. Nc 15 years later, the same basic unit gives 175 b.h.p, norma aspirated and 225 b.h.p. when turbocharged, the most marli physical change having been a slight increase in bore s to raise the capacity to 4.3 litres.

Progress has taken place also in respect of the greater of the C.A.V. DPA distributor pump (Stand 231), which now acknowledged to give enhanced engine-performance ch acteristics, and the gradual adoption of improved main a -end bearing materials—such as reticular-tin on aluminium o cope with high loadings without detriment to bearing . Some nianufacturers are at least showing signs of greater ,ling-system consciousness, particularly Leyland Motors who some years now have been using a "sealed" no-loss iling system and are now making the Smith's magnetic. tide thermostatically controlled fan drive (Stand 226), which [ow available on certain underfloor-engined passenger chassis. larhilst on the subject of engine progress, mention must be de of the Perkins 6.354 six-cylinder direct-injection unit and 416), the output of which has recently been raised from ! to 120 b.h.p. This unit looks like proving to be one of the st satisfactory designs of its size to have been developed this country since the war, its success being indicated by the iwing number of vehicle manufacturers who are fitting it, the favourable reports from operators.

fhe engine picture is not all bright, however. The adoption turbocharging as standard is depressingly slow (exceptions ng Thornycroft (Stand 73) and Foden), whilst there have al cases recently of excessively high engine ratings causing ket-sealing and cylinder liner troubles: it is not always ;sible to get away with the "quarts into pint pots" principle! ne engines introduced in the past few years are decidedly noisy, both from the mechanical and the combustion lects, whilst engine-exhaust silencing needs looking into also.

One last word on engines. When is a universal standard for power ratings going to be adopted?

The only really big transmission news is the Bristol Siddeley S.R.M. automatic gearbox, built under licence from the Swedish company, Svenska Rotor Maskiner A.B., and installed initially in the E.R.F. eight-wheeler previously referred to. Development work is being carried out at present in Sweden with regard to the application of this transmission in heavy goods vehicles, its worth in buses and off-the-road machines already having been proved.

Records show that, although the use of this transmission can result in anything up to 20 per cent, heavier fuel consumption, invariably a 10 per cent. improvement in average speed is returned, the time saved far outweighing the extra fuel used. Further acknowledged advantages have been ease of driving and reduced engine and rear axle wear. It will be interesting to watch the progress of this transmission in Great Britain: already certain important passenger-vehicle manufacturers and operators are known to be very intrigued, and they will be taking delivery of boxes for trial service later this year.

It seems likely that definite news will be available S0011 of progress in hydrostatic transmissions. Already there are at least two different systems fitted to development vehicles, with a third nearing the stage of road trials, whilst at the Farnborough aircraft show earlier this month the Houchin selfpropelled ground power unit with this type of transmission was

displayed. This has a Perkins 6.354 engine driving an alternator which, for vehicle propulsion, drives a variable-displacement hydraulic pump. The Houchin machine is capable of 30 m.p.h.

Turning to more conventional transmissions, the five-speed gearbox is starting to become commonplace—albeit at extra cost --in medium-capacity chassis, although synchromesh does not seem to be making any headway in heavy-vehicle designs. An interesting new gearbox is the Foden seven-speed unit, which has two layshafts for first, second and reverse, an arrangement which gives the advantage of high .torque capacity without excessive gear-wheel size.

Several interesting axles have been developed recently by such concerns as Kirkstall (Stand 412) and Moss (Stand 218), including double-reduction units, whilst noticeablethis year for the first time are several examples of the Eaton two-speed tandemdrive design (Stand 248) which is particularly useful in heavy chassis to compensate for inadequate engine power. Despite the increasing number of double-reduction and bevel-gear axles to be found on current heavy vehicles, the worm is by no means dead and it still offers many advantages when properly designed and applied, as in the case of Foden vehicles.

Mention must be made here of third-axle conversions, which do not appear to be waning in popularity. All Wheel Drive, Ltd., have a Bedford TK in the Demonstration Park with a double-drive conversion, an interesting feature of which is the cranked chassis frame over the bogie to give maximum interaxle articulation, whilst Universal Power Drives, Ltd. (Stand 68), show a bogie developed for the Commer 8-tonner which has four-spring suspension and the Eaton tandem-drive axles.

Brakes are a particularly. sore point with me at the moment. Too many laden vehicles which I have tested recently have been shown to have poor braking performance, generally because of excessive rear-wheel locking. In this respect the new Lockheed anti-locking device for application to rear brakes (Stand 343) is more than welcome. I feel that bad design causes excessive rear-brake locking, as several manufacturers have shown that they can produce four-, sixand eight-wheelers that are not prone to wheel locking. If some concerns can do this everyone ought to be able to.

Braking of articulated vehicles, also, is generally poor, with too-few signs of cooperation between tractive-unit and semitrailer manufacturers to alleviate the position (the Foden-Dyson "

matched" artic is an exception here). It is sad to recall that in most cases an operator has to specifically ask for—and pay extra for—a tractor protection valve: in the event of a semitrailer breaking away its brakes are applied automatically, but the tractive unit is left without a footbrake!

Where are the disc brakes that six years ago were going to provide the solution to all our troubles? Disc brakes could eventually achieve general recognition among the lighter classes of vehicle; but, so far as heavy goods chassis are concerned, o24

they have only, for the most part, introduced new problei without solving any of the old ones. They can he, howev, satisfactory on axles subjected to loadings of 4 tons or less.

Braking of the rear wheels is more of a problem, howev, and the drum is likely to remain with us for many more years even if it does have to be controlled to prevent, excessive lockir Wheel locking is a particular problem with rear-bogie axles, recently introduced device intended to overcome this havi been developed by Henry Boys and Sons, Ltd. (Stand 32 this consisting of a hydraulic cylinder which resists lifting of t rear axle during heavy braking. The Leyland non-reactive int, linked four-spring suspension appears to have been anott reasonably successful solution and, in addition to being used Albion and Leyland, it has been adopted also by Primrc (Stand 362) and Dodge, whilst the Eaton-Hendrickson walkir beam layout minimizes wheel hop also.

Leaf Springs Prosper

The leaf-spring continues to hold sway in this country w air-suspension tending, if anything, to recede in the backgrour although A.E.C. have developed a satisfactory system application to Mercury goods chassis (Stand 142) and Rel and Reliance passenger models, although a weight pena of up to 5 cwt. has to be paid. The superiority of the h for light cross-country vehicles is shown by the adoption such springs as alternative equipment on the latest Aus. Gipsy (Stand 57); but for heavier machines a superlative c the-road performance is given by fully independent suspensic such as the torsion-bar system of the Alvis Stalwart 5-t amphibious load carrier (Stand 69). So far as leaves are cc cerned the use of rubber and polyurethane bushes gis freedom from the need for lubrication, and these have be adopted recently by such concerns as Foden and Vauxhall.

The news so far as steering gears are concerned is t relatively meteoric rise in popularity of Burman recirculatir ball gears, the high efficiencies of which eliminate the need f steering servos, providing the rest of the geometry is corre Tyres are having an increasing effect on vehicle desi nowadays. For example, radial-steel tyres of the type pioneer by Michelin (Stand 188) are now being manufactured uric licence by most of the important British companies and making it possible to use 16-in, wheels on quite large vehiel with resulting reduction in frame height. There is no reas to think that the capacity ratings of such equipment will r continue to be increased. Tubeless tyres look like reachi a point of general acceptability soon, and these can sa valuable weight as can also low-profile tyres such as t Goodyear Super Single (Stand 184), which replace twinn equipment and save weight, allow a better flow of air to brakes and give improved flotation.

I have tried to show in this article that, basically, Briti commercial-vehicle designs are as good as those of any ott country, but that in certain instances they are being let do' by insufficient attention to detail. I hope to be able to rep■ that the loose ends have been tied up when 1 record the 19 London Commercial Motor Show.