BEER IS BEST WHEN

Page 34

Page 35

Page 36

If you've noticed an error in this article please click here to report it so we can fix it.

IT GOES BY ROAD

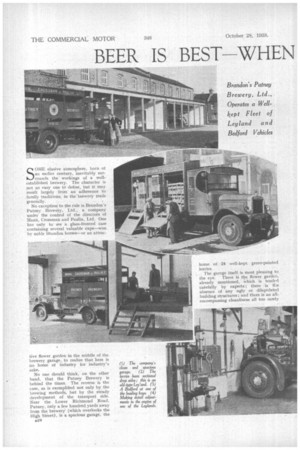

Brandon's Putney Brewery, Lid., Operates a Wellkept Fleet of Leyland and Bedford Vehicles

The Condition of Each Lorry Pays a Striking Tribute to the Maintenance Methods of the Company S0:41E elusive atmosphere, born of an earlier century, inevitably surrounds the workings of a wellestablished brewery. The character is not an easy one to define, but it may result largely from an adherence to family traditions, in the brewery trade

generally. ., No exception to the rule is Brandon's Putney Brewery, Ltd.. a company under the control of the directors of Mann, Crossman and Paulin, Ltd. One has only to see a glass-fronted case containing several valuable cups—won by noble Brandon horses—or an attrac tive flower garden in the middle of the brewery garage, to realize that here is no home of industry for industry's sake.

No one should think, on the other hand, that the Putney Brewery is behind the times. The reverse is the case, as is exemplified not only by the brewing methods, but by the steady development of the transport side. Near the Lower Richmond Road, Putney, only a few hundred yards away from the brewery (which overlooks the High Street), is a spacious garage, the BIM home of 24 well-kept green-painted lorries.

The garage itself is most pleasing to the eye. There is the flower garden, already mentioned, which is tended carefully by experts ; there is tlie absence of any ugly or dilapidated building structures ; and there is an all• encompassing cleanliness all too rarely found where a fairly large fleet of vehicles is kept. True, the old Brandon stables were converted, to make this garage, but the job was done neatly and well. An interesting point is that the garage is effectively heated.

Here, too, are useful personal facilities for the company's drivers (a happy, enthusiastic crowd). These include toilet accommodation, a room in which to store clothes, and a canteen.

Nearby, one finds a fair-sized workshop, a building where crate-repairing is carried out, and, of course, the garage-foreman's office. Fuel and oil supplies are available on the premises. Although the company operates a large motor fleet, six prize-winning horses are still in commission, their quarters being a stable in a corner of the garage. Before leaving the subject of the garage, it is of interest to note that a large rain-water butt forms part of the equipment. This company is particular about the kind of cooling water used in its vehicles.

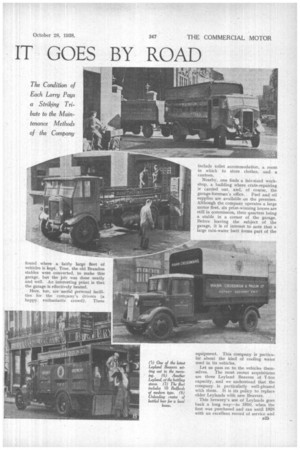

Let us pass on to the vehicles themselves. The most recent acquisitions are three Leyland Beavers of 7-ton capacity, and we understand that the company is particularly well-pleased with them. It is its policy to replace older Leylands with new Beavers.

This brewery's use of Leylands goes back a long way—to 1910, when the first was purchased and ran until 1928 with an excellent record of service and reliability. That was the first motor vehicle employed by Brandon's Putney Brewery, Ltd. Subsequently, Leylands were consistently purchased, although one or two steamers were also in use. Several of the 14 Leylands now employed are veterans, still giving excellent service and looking well preserved. Some of the older machines are 4-tonners and others 6-tonners.

In addition to the Leylands, there are 10 late-model Bedfords_ Six are of 30-cwt. capacity, whilst there are two 3-tonners, one 2-tonner and an 8-cwt. van. Here, again, the company is most satisfied with the service that they are giving. Finally, there is a Foden steamer, whilst two trailers, of 3-ton and 4-ton capacity respectively, supplement the lorries.

Closed-type Bodies.

The bodies, of a special type, are built • for the brewery by Messrs. Whitmee and Sons, of York Road, Battersea. Open-type lorries, although favoured by many concerns for the carriage of crates, are not used by this company. The bodies are roofed, and. in most cases, the sides are each divided into three parts, whicli drop independently, to form loading ramps. Reconditioning of the Bodies is not carried out by the brewery company, but by Messrs. Whitmee and Sons. What happens, actually, is that each body is sent to that firm for this purpose, when the particular vehicle is being given its major overhaul.

Mechanical maintenance of the fleet is carried out in the workshop at the garage. This shop is well equipped with the latest tools, and is kept spotless. Such major operations as reboring aie, of course, done by outside concerns. Each vehicle is given a major overhaul once every three years, . oil being changed every 1,000 miles.

Attention to Cleanliness.

Most notable is the manner in which the company keeps every part of each vehicle free from oil, dust or grit. An example of how far this excellent policy is carried is provided by the knowledge that even crankcases are .hand-scraped and buffed until they shine as though they were plated. It is a joy to look upon the engines of the older Leylands, and to see the condition in which aluminium, copper and brass parts are kept. Paintwork, on the engine parts. is eliminated so far as possible, since cleaning is thereby facilitated and crack detection is possible.

A similar degree of cleanliness is given to all chassis parts and the result is not only a feeling of satisfaction th all concerned with the use of the lorries, but material advantages in lessening depreciation and in making possible the estimation of imminent renewals.

As regards washing and polishing, it is obvious that these operations are performed frequently. We were informed, however, that it has not been possible to wash the lorries so regularly since the restriction on drivers' working hours. Before that legislation came s26 into force, Saturday mornings were devoted to the task, but now the men have to make use of such opportunities as arise, since they are also engaged in driving on Saturdays.

We must now consider the work which the fleet has to do. This is, almost without exception, confined +o handling the finished product, for the raw materials are purchased for direct delivery to the brewery. Roughly 40 per cent, of the demand experienced by the company is for bottled beer, and the remaining 60 per cent. for draught beer. The former is delivered in crated half-pint, pint or quart bottles, and the latter in casks.

The premises are divided into two main parts—the bottling stores and the brewery proper. At the brewing department, the loading bays accommodatesix lorries, and the same applies to the bottling stores, whilst there is, of course, other and adequate accommodation for unloading.

Generally speaking, the lorries are fairly heavily loaded, but excess loafing is impossible, at any rate in the case of bottled beer. Roughly, 100 crates go to a ton, but this figure varies according to the size of the bottles and mixed loads are common. Draught beer is delivered in pins (4*

gallons), firkins (9 gallons), kils (18 gallons) and barrels (36 gallons). Taking an example of transport of this type of product, the Foden, with trailer. carries 10i tons.

The radius of working extends as far as 75 miles, but on the average is probably nearer 35 miles. The aggregate annual mileage of the fleet is approximately '275,000. The six 30-cw1:. Bedfords did 42,000 miles in a recent period of six months.

The Festive Rush.

At Christmas time, when the brewery has its busiest period, the plan is adopted of employing spare men to drive the lorries up from the garage to the loading bays. Little difficulty. is thus caused by the drivers' hours regulations, for the regular men can take

over the lorries from the bays. The drivers, as a matter of interest, receive a standing wage and commission based on " tonnage out" and " empties back."

In conclusion, we would mention that although there is no transport manager. as such, control of the fleet is carried out with efficiency and economy by the bead brewer, Mr. E. H. Allard. and the second brewer, Mr. C. E. Lanfear.