TOOLS AND APPLIANCES AT THE MOTOR SHOW

Page 33

Page 34

If you've noticed an error in this article please click here to report it so we can fix it.

The Second Instalment of a Survey of those Exhibits at Olympia which were of Interest to Users of Commercial Motor Vehicles,

IN OUR first article (appearing in last week's issue) dealing with the tools, appliances and garage accessories shown at Olympia, we described and illustrated mainly those -which were of large dimensions, such as battery-carrying trucks, universal-bearing boring machines, geartesting devices, engine stonds, grinding machines, milling machines, hauling drum winch gearing, jacks for use with large tyres, etc.. This week we .propose to cover some of the smaller tools and appliances.

K.B. Tools.

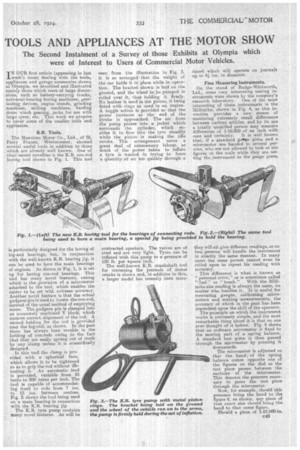

The Mansions Motor Co., Ltd., of 78, Petty France, Westminster, showed several useful tools in addition to those which are already well known. One of their recent novetties is the K.B. con-rod hering tool shown in Fig. 1. This tool

is particularly designed for the boring of big-end bearings, but., in conjunction with the well-known K.B. bearing jig, it can be used to bore the main bearings of engines. As shown in Fig. 1, it is set up for boring con-rod hearings. This tool has many novel features, among which is the .provision of a micrometer attached to the tool, which enables the cutter to be set with extreme accuracy. Another novel feature is that the actual gudgeon pin is used to locate the con-rod, instead of the usual method a employing cones. The gudgeon pin is clamped into an accurately machined V block, Which ensures correct alignment of the rod. A second holding for the rod is provided near the big-end, as shown. In the past there has always been trouble in the holding of con-rods owing to the fact that they are easily sprung out of truth by any clamp unless it is scientifically designed.

In this tool the clamp is provided with a spherical face, which allows it to be tightened so as to grip the rod without Ostorting it. An automatic feed is provided, variable from 25 turns to 200 turns per inch. The tool is capable of accommodatleg itself to rods from 7 ins. to 15 ins, between centres. Fig. 2 shows the tool being used on a main bearing in connection with the K.B. bearing jig. The K.B. tyre pump contains many novel features. As will be seen from the illustration in Fig. 3, it is so arranged that the weight of the car holds it in place while in operation. The bracket shown is laid on the ground, and the wheel lobe pumped is rolled over it, thus holding it firmly. No leather is used in the piston, it being fitted with rings as used in an engine. A toggle action is provided so that the power increases as the end of the stroke is approached. The air from the pump passes into a jacket which surrounds the cylinder, which enables it to flow into the tyre steadily while the piston is making the idle stroke. This arrangement saves a great deal of unnecessary labour, as much of the power taken to inflate a tyre is wasted in trying to force a quantity of air too quickly through a

contracted aperture. The valves are of steel and are very light. Tyres can he inflated with this pump to a pressure of 120 lb. per square inch. The well-known K.B. crankshaft tool for correcting the journals of motor cranks is shown and, in addition to this, a larger model has recently been intro

dueed which will operate on journals up to zle ins, in diameter.

Fine Measuring Instruments.

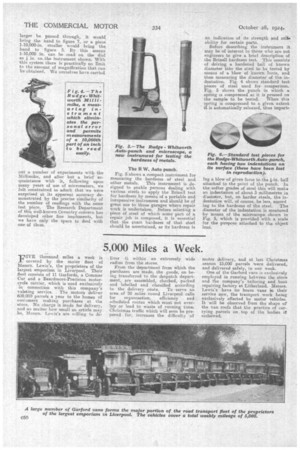

On the stand of Rudge-Whitworth, Ltd., some very interesting testing instruments were shown by the company's research laboratory. One of the most interesting of these instruments is the Millimike, shown in Fig. 4, as this invention provides a new means of measuring exesemely small differences between various articles, and by its use a totally unskilled person may measure differences of 1-10,000 of an inch with ease and certainty. It is well known that, if a standard gatteee piece and a micrometer are handed to several persons, who are not allowed to look at the figures on the scale while they are setting the_instrurnont to the gauge piece, they will all give different readings, as no two persons will handle the instrument in exactly the same manner. In many eases the same person cannot even be relied upon to repeat his reading with accuracy.

This difference is what is known as "personal error," or is sometimes called "feel " or " touch." With the Millimike the reeding is always the same, no matter who handles it. It is useful formeasuring gauges, calibrating micrometers and making -measurements, the accuracy of which in the past has been dependent upon the skill of the operator. The principle an which the instrument works is extremely simple, and the most remarkable thing a-bout it is that no one ever thought of it before. Fig. 4 shows that an ordinary micrometer is fixed to the moving part of a spring balance. A standard test piece is then passed through the micrometer by pressing it downwards.

The micrometer is adjusted so that the hand; of the spring balance comes opposite one of the figures on the dial as the test piece passes between the surfaces of the micrometer. This denotes the pressure necessary to press the test piece through the micrometer. Now, for example, should this pressure bring the hand to the figure 6, as shown, any piece of that exact size should bring the hand to that same figure.

Should a piece of 1-10.000-in. C49 larger be passed through, it would bring the hand to figure 7, or a piece 1-10,000-in. smaller would bring the, hand to figure 5. By this means 1-10,000 in. can be read on the dial as 4. in. on the instrument shown. With this system there is practically no Emit to the amount of magnification that can he obtained. We ourselves have carried out a number of experiments with the Millimike, and after but a brief acquaintance with it, following upon many years of use of micrometers, we felt constrained to admit that we were surprised at its apparent accuracy demonstrated by the precise similarity of the number Of readings with the same test piece. The Research Department of this well-known Coventry concern has developed other fine implements, but we have only the space to deal with one a them.

The R.W. Auto-punch.

Fig. 5 shows a compact instrument for measuring the hardness . of steel and

other metals. This instrument. is designed to enable persons dealing with various steels to apply the Brinell test for hardness by means of a portable and inexpensive instrument and should be of great use to those garages where repair work is undertaken. Before selecting a piece of steel of which some part of a repair job is composed, it is essential that the exact hardness of that steel shoui& be ascertained, as its hardness is

an indication of its strength and suite ability for certain parts.

Before describing the instrument it may be of interest to those who are not engineers to give a brief description of the Brinell hardness test. This consists of driving a hardened ball of known diameter into the steel to be tested by means of a blow of known levee, and -then measuring the diameter' of the indentation. Fig. 6 shows standard test pieces of steel used for comparison. Fig. 5 shows the punch in which a spring is compressed as it is pressed on. the sample to be tested. When this spring is compressed to a given extent it is automatically released, thus impart ine a blow of given force to the i-in. ball attached to the point of the punch. In the softer gra,des .of steel this will make an indentation of about 3 millimetres in diaineter, but, on harder steels, the indentation will, of course, be less, accord ing to the hardness of the steel. The diameter of the indentation is measured by means of the microscope shown in Fig. 5, which is provided with a scale for the purpose attached to the object lens.