Facilitating the Handling of Awkward Loads.

Page 31

If you've noticed an error in this article please click here to report it so we can fix it.

IN these days of strenuous competition the chief aim of the principals of any go-ahead business house is to endeavour to reduce unnecessary expenditure, and one of the greatest causes of loss of both time and money is in connection with the loading and unloading of motor vehicles. Any system which will assist in the lessening of these delays must, therefore, merit more than passing interest.

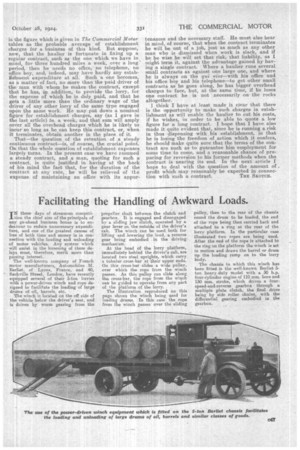

The well-known company of French motor manufacturers, Automobiles M. Berliet, of Lyons, France, and 40, Sackville Street, London, have recently equipped several of their 5-ton lorries with a power-driven winch and rope designed to facilitate the loading of large drums of oil, barrels, etc.

The winch is located on the off side of the vehicle below the driver's seat, and is driven by worm gearing from the

propeller shaft between the clutch and gearbox. It is engaged and disengaged by a sliding jaw clutch, operated by a gear lever or, the outside of the driver's cab. The winch can be used both for lifting and lowering the load, a reverse gear being embodied in the driving mechanism.

At the head of the lorry platform, immediately behind the driver's cab, are located two steel uprights, which carry a tubular cross-bar at their upper ends. On this cross-bar slides a wide pulley, over which the rope from the winch passes. As this pulley can slide along the cross-bar, the rope from the winch can be guided to operate from any part of the platform of the lorry. The illustration reproduced on this page shows the winch being used for loading drums. In this case the rope from the winch passes over the sliding

pulley, then to the rear of the chassis round the drum to be loaded, the end of the rope being then carried back and attached to a ring at the rear of the lorry platform. In the particular case illustrated two ropes are being used. After the end of the rope is attached to the ring on the platform the winch is set in motion and draws the barrel or drum up the loading ramp on to the lorry body.

The chassis to which this winch has been fitted is the well-known Berliet 5ton heavy-duty model with a 30 h.p. four-cylinder engine of 110 mm, bore and 130 mm. stroke, which drives a fourspeed-and-reverse gearbox through a multiple plate clutch, the final drive being by side roller chains, with the differential gearing embodied in the gearbox.