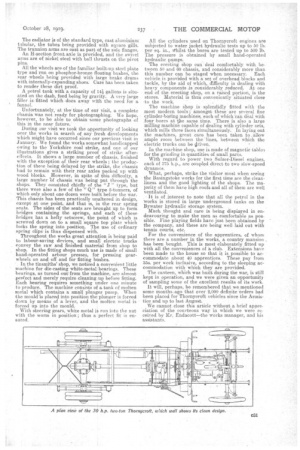

THE 30 H.P. TWO-TON THORNYCROFT.

Page 15

Page 16

Page 17

If you've noticed an error in this article please click here to report it so we can fix it.

The " B.T." Type Remodelled with a New Engine Having Many Distinctive Features

VEIIICLES OF Thornycroft make have long been renowned for the excellence of their design and for their durability in service. During the war,'5,000 of the "J" type were supplied to the Army, and they proved that this was one of the most successful types in service. The Thornycroft programme now includes the 5-ton " Q " type, the 4-ton

type (W.D. model), the "X type (which is a lightened .edition of the W.D. model), and an entirely new model of the "B.T." type: It is with this lastnamed model that we shall deal, in particular; in this article.

The most interesting part of this chassis is the engine, aS it is one of the first examples of Britishbuilt lorry engines showing strong marine, and, 'even, American, tendencies, It is a fOur-cylindered engine in which the cylinders are cast in one with the top half of the crankcase. This construction necessitates the use of a separate casting comprising the cylinder heads. Another interesting feature lies in the positioning of the valves. The exhaust valves are in the normal position, whilst the inlet valves are of the overhead type; Aluminium cages are provided'for the lat ter, and these cages contain the rocker arms, which are operated by long tappets passing through holes in the cylinder casting. •

Attention to detail is shown by the fact that the -valve cages are each provided with small oil receptacles, the valve stems being lubricated by means of wicks.

There is only one camshaft, and the tappets arc contained in two cast-iron, cages, each of which holds a set of four. These cages are not bushed, but'they are, of course, well lubricated by oil from the crankcase, and the wearing surfaces very quickly attain a glass-like polish. Each set of tappets is contained in recesses between its tWo cylinders and is entirely enclosed by a D-shaped cover provided with a thumbscrew.

The inlet valves are situated directly over the exhaust valves ; the incoming gas, therefore, tends to keep the exhaust. valves cool and minimize the risk of valve distortion. • The cylinders have a bore of 4 ins. and a stroke of 5 ins., and the nominal h.p. is 30; actually considerably more than this is developed. The magneto and , centrifugal-type governor are driven by a cross-shaft at the front of the engine, the governor operating directly on a butterfly valve ituatecl above the ordinary throttle in the inlet pipe. The magneto is driven through a flexible leather coupling.

The carburetter is a Solex, which obtains its hot air supply from a muffle placed round the exhaust connection. The'gear-type oil pump is situated inside the crank case. It is driven by a small roller chain, a somewhat unusual practice, but one which is giving very satis. factory results. As in other types of Thornyeroft engines, the centrifugal water pump forms a bracket for the fan and is driven by a shaft from the latter ; this shaft is. pro-. vided at its front end with a universal joint. The fan itself is driven by a pulleyon an extension of the camshaft end by a Whittle belt..

With some chassis, trouble is occasionally experienced because the starting handle, owing to frame distortion, gets out of line with' the crankshaft. This has been overcome in the " B.T." engine by4Tfitting the starting handle as' part of the engine. To. enable this to be done, a bracket protrudes from the timing gear case cover, and the starting handle shaft runs in .ball bearings at its forward end.

:The oil level gauge consists of a little float to which is attached a long aluminium tube. The pressure of the oiling system is 10 'lb. per sq. in., an oil relief valve being fitted over the timing gears. so that any excess oil pours on to thelatter. Theoil ' upon which much of the efficiency and long life of tlle engine depend, has been designed With particular care.

It consists of a perforated metal tube containing a carton of cambric or similar material by which every particle of dirt is removed from the oil. This filter rims the entire length of the engine and is similar tO

those which were used on the coastal motor boat engines.

Other details in the design of the engine include offset rollers for the operation of the valve tappets ; this offsetting gives the valves a quick .opening and slow closing. A neat gland is fitted to the water pump spindle; this gland is composed of split white metal rings separated by rubber rings. As it is compressed, the rubber rings compress the white metal rings on to the shaft, making a water-tight joint. The overhead-valve tacker arm cages can each be removed by undoing twoinuts only ; the long tappets are then exposed to view. A large inspection cover is bolted on to the top half of the crankcase, and this cover carries an oil filler with a large orifice; the latter is' protected from the entry of dirt and dust by a lid held in place by a spiral spring.

The first engine of this type to be built was fitted into the motor boat which won the recent race from London to Cowes' a remarkable performance, especially.censidering that this was the first real run the engine had had after leaving the test bench.; as a matter of fact, the engine was in the works on the Thursday and the race was run on the, fallowing Saturday.

Apart from the engine, the " B.T." chassis is practically a small edition oPthe W.D. J" type.

The frame is of channel section pressed steel, both the engine and gearbox being suspended on this on the three-point system, so that twisting of the frame members over uneven roads does not strain the castings. The dumb irons, which are of .cast steel, are carried well hack into the channels.

The clutch is a pressed steel cone lined with Ferodo. It is of large diameter and has easily accessible springs; there are two of the latter and they are of the laminated type. The gearbox is a one-piece casting provided with a large inspection cover. It gives three speeds' forward and a reverse. The designers have considered it unnecessary to provide a fourth gear owing to the great power which the engine develops. The primary and secondary shafts rim on ball bearings, am:1'a ball thrust is situated behind the brake drum.

At an engine speed of 1,001) r.p.m., the road speeds are: first gear, 3.8 ; second gear, 7:75; third gear, 13.5; reverse, 3.8. The change-speed lever and quadrant are carried on an extension of the gearbox lid. The transmission brake islwide and of largo diameter ; as is usual, it is of the contracting type and fitted with cast-iron liners.

A leather universal joint is situated between the clutch and gearbox. The drive to the rear axle is taken through a tubular propeller shaft provided with two leather universal joints ; these 'joints are of the same dimensions as those fitted to the subsidy model, and as they have given satisfaction in this model they should certainly do well on the lighter chassis.

The final drive is by worm gearir t -of the Lancheate type. Great care has been taken properly to position the worm, which, with this type of gear, is of the utmost•importance. The axle itself is of the " pot " type, the worm arxl differential being slung from the top cover. The spring seats are bolted direct to extensions of the central eae.ting. As. is usual, -steel tubes are pressed into each side. The radiator is of the standard type, cast aluminium tubular, the tubes being provided with square gills. The trunnion arms are cast as part of the side flanges. An H-section front axle is provided, and the swivel arms are of nickel steel with ball thrusts on the pivot pins.

All the wheels are of the familiar built-up steel plate type and run on phosphor-bronze floating bushes, the rear wheels being provided with large brake drums with internally-expanding shoes: Care has been taken to render these dirt proof.

A petrol tank with a capacity of 144 gallons is situated on the dash, feed. being by gravity. A very large filler is fitted which does away with the need for a funnel.

Unfortunately, at the time of our visit, a complete chassis was not ready for photographing. We hope, however, to be able to obtain some photographs of this in the near future.

During our visit we took the opportunity of looking over the works in search of any fresh developments which might. have occurred since our previous visit in January. We found the works somewhat handicapped owing to the. Yorkshire coal strike, and one of our illustrations gives a striking proof of strike aftereffects. It shows a large number of chassis, finished with the exception of their rear wheels; the production of these being delayed by the strike, the chassis had to remain with their rear axles packed 'up with wood blocks. However, in spite of this difficulty, a large number bf chassis was being put through the shops. They .00nsisted chiefly of the "J" type, but there were also a few of the "Q" type 5-tonners, of which only about one dozen were built before the war. This chassis has been practically unaltered in design, except at one point, and that is, in the rear spring seats. The sides of the seats are brought up to form bridges containing the springs, and each of these bridges has a hefty setscrew, the point of which is screwed down on to a small square top plate which locks the spring into position. The use of ordinary spring clips is thus dispensed with. Throughout. the works great attention is being paid to labour-saving devices, and small electric trucks convey the raw and finished material frenn shop to shop. In the fitting shops much use is made of small hand-operated arbour presses, for pressing gearwheels on and off and for fitting bushes.

In the tinsmiths' shop, we noticed a convenient little machine for die-casting white-metal bearings. These hearings, as turned out: from the machine, arc almost per,ect and merely require cleaning up before fitting. Each bearing requires something under one minute to produce. The machine consists of a tank of molten metal which contains a small plunger pump. When the mould is placed into position the plunger as forced down by means of a lever, and the molten metal is forced up into the mould.

With steering gears, white metal is run into the nut with the worm in position ; thus a perfect fit is ensured. All the cylinders used on Thornycroft engines are subjected to water jacket hydraulic tests up to 50 lb, per sq. in., sShilst the bores are tested up to 500 lb. The pressure is obtained by small hand-operated hydraulic pumps. The erecting. shop can• deal comfortably with between 50 and 60 chassis, and considerably more than this number can be staged when necessary. Each vehicle, is provided with a set of overhead blocks and tackle, by the aid of which, d'ifficulty in dealing with heavy components is considerably reduced. At one end of the erecting shop, on a raised portion, is the stores. Material is thus conveniently sitnated close to the work.

The machine shop is splendidly fitted with the most modern tools • amongst these are everal fine cylinder-boring macines., each of which can deal with four hoses at he same time. There is also a large milling machine capable of dealing with cylinder sets, which mills three faces simultaneously. In laying out the machines, great care has been taken to .allow ample room between the 'lines, between which the electric trucks can be driven.

In the machine shop, use is made of magnetic tables for the grinding in quantities of small parts. With regard to power two Sulzer-Diesel engines, each of 375 h.p., are coupled direct to two slow-speed dynamos. What, perhaps, strike the visitor most when seeing the Basingstoke works for the first time are the cleanliness and the good lighting of the shops. The majority of them have high roofs and all of them are well ventilated.

It is of interest to note that all the petrol in the works is stored in large underground tanks on the Bywater hydraulic storage system.

Mitch thought and care is being displayed in endeavouring to make the men as comfortable as possible. Fine playing fields have just been obtained by the company, and these are being well laid out with tennis courts, etc.

For the convenience of the apprentices, of whom there are a number in the works, a country mansion. has been bought. This is most elaborately .fitted up with all the conveniences of a club. Extensions have been made to the house so that it is possible to accommodate about 40 apprentices. These pay from 35s. per week inclusive, according to the sleeping accommodatioji with which they are provides'.

The canteen, which was built during the war, is still kept in operation, and we were given an opportunity of sampling some of the excellent results of its work.

It will perhaps, be remembered that we mentioned some inonths.a.go that over 2,000 definite orders had been placed for Thornycroft vehicles since the Armistice and up to last August. We cannot close this article without a brief appreciation of the courteous way in which we were received by Mr. Enda,cott—the works manager, and his assistants.