LOW GRADE FUELS FOR STEAM WAGONS.

Page 8

Page 9

If you've noticed an error in this article please click here to report it so we can fix it.

Boiler Modification Necessary for Securing Satisfactory Results.

THE • PRESENT DIFFICULTY of obtaining Welsh steam coal for motor wagons has raised the question of using other kinds of fuel, such as bituminous coal or coke. The recent tests by the Coal Controller with these two fuels give very little information as to how they can best be used, and the object of this article is to describe the conditions necessary for their proper combustion, and suggest the best methods of securing them on steam wagon boilers.

Before proceeding further it must be clearly understood that the majority of wagon boilers, and most decidedly those of the loco type, are designed exclu-) sively for Welsh steam coal. It is most certain that these alternative fuels cannot successfully be used without alterations to the furnace other than merely' changing the firebars, for each fuel requires entirely different conditions for proper combustion.

Bituminous Coals.

Dealing with bituminous coals, the first point to consider is its heating value as compared with Welsh coal. A fair average figure for the former is 12,500 B.T.U.s per lb.' and for the latter 14,500 B.T.U.s per lb., so that 1* lb. of bituminous coal has the same heating value as 1 lb. of Welsh coal. Another dis advantage is that it does not burn as easily as Welsh coal, because a certain amount of heat is first required to distill the gas in the coal, and also it has a tendency to cake or form a sticky mass which impedes the mixing of the air with the burning fuel. For these reasons a larger grate area is really necessary,. but, of course, is unobtainable on existing boilers. Consequently it is impossible to drive a wagon as fast with this fuel as with Welsh coal, and this is an inherent defect which cannot be overcome.

Because of thellarge amount of gas given off by bituminous coal, it should have a large combustion space above the fire, so that the gases can be properly B28 consumed before they strike the heating surface of the boiler. If not, the unburnt gas will be cooled down, forming soot and smoke. Best results are also obtained with this coal when the furnace is lined with refractory material ; this becomes incandescent and completes the combustion of the gases before they pass to the heating surface, and comes especially into action when fresh fuel is thrown on the fire.

When fresh fuel is fed, a large amount of gas is quickly given off and an extra amount of air is immediately required which cannot be supplied through the fire. To remedy this an additional air supply should be arranged above the fire. This must be cut off when the coal has finished giving off the volatile gas, or else an excess amount of air will pass into the furnace, over and above the amount required for complete combustion of the remaining fuel. This would reduce the temperature of the heating gases and consequently lower the efficiency of the boiler.

It is evident that the smaller the quantity of fresh coal fed the more easily will proper combustion be attained. The ideal way is by mechanical stoking, where the fuel is fed continuously, but this, of course, is unpracticable on motor wagon boilers Coming now to the application of these principles to existing boilers, it is evident that they cannot all be applied. As already stated, the grate area cannot be increased, but this can be balanced to a certain extent by increasing the draft. This is done by fitting a smaller ferrule in the nozzle of the exhaust blast pipe, about Iv in. smaller than for Welsh coal ; although by doing so the power of the engine is decreased because of the increased back pressure on the piston, but this cannot be helped.

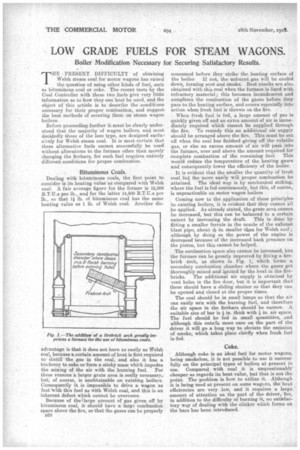

The combustion space also cannot be increased, but the furnace can be greatly improved by fitting a firebrick arch, as shown in Fig. 1, which forms a secondary combustion chamber where the gases get thoroughly mixed and ignited by the heat in the firebricks. The additional air supply is obtained by vent holes in the fire door, but it is important that these should have a sliding shutter so that they Can. be opened and closed at the proper times.

The coal should be in small lumps so that the air can easily mix with the burning fuel, and therefore the air space in the firebare should be narrow. A suitable size of bar is * in. thick with I in. air space. The fuel should be fed in small quantities, and ' although this entails more care on the part of the driver it will go a long way to obviate the emission of smoke, which takes place chiefly when fresh fuel is fed.

Coke.

Although coke is an ideal fuel for motor wagons, being smokeless, it is not possible to use it successfully on the principal types of boilers at present in use. Compared with coal it is unquestionably cheaper as regards its heat value, but that is not the point. The problem is how to utilize it. Although it is being used at present on some wagcris, the heat efficiencies are very low, and it requires a large amount of attention on the part of the driver, for, in addition to the difficulty of burning it, no satisfactory way of dealing with the clinker which forms on the bars has been introduced. The practice is to run until the fire begins to burn dead, and then dump it all out, scrape the clinker off the bars, and remake the fire using the best part of the old one. Another factor in the use of coke is the great variation in its condition. Whereas good Welsh coal contains under 2 per cent, of ash and practically no moisture, coke is being sold to-day containing as much as 15 per cent, ash and 15 per cent. moisture, the latter being due to excessive quenching. It is therefore evident that it requires a vastly different furnace from that necessary for Welsh coal.

It is consequently utterly impossible to get anything like the same result with coke as with coal on an existing boiler, and it is only possible to drive the wagon at a much slower rate, unless the wagon was designed with a, much higher-powered boiler than was necessary to give maximum legal speed with Welsh coal.

As the combustion of coke takes place chiefly on the firebars, it is evident that all the heating surface should be, practically speaking, in the firebox. In the loco type boiler, however, only 20 to 25 per cent. of the total heating surface is in the firebox. As previously mentioned, to use coke successfully some means must be provided for dealing with the clinker. Two methods are possible for doing this :— (1) Self-clinkering grates which automatically break up and throw out the clinker, and (2) specially constructed grates which aim at precluding any forma. don of clinker' the ail coming away in the form of dust or small friable lumps and dropping into the ashpan the same as with coal.

The first method is too elaborate for steam wagon boilers, and, therefore, the second must be employed. To prevent clinker formation it is necessary to keep the unbars cool, and this can be done by a steam jet in the ashpit which not only cools the bars, but helps to create the draft. Another way is always to keep water in the ashpan, but this is not very efficient and also requires a lot of attention.

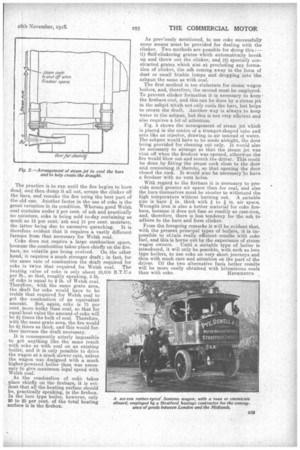

Fig. 2 shows the arrangement of steam jet which is placed in the centre of a trumpet-shaped tube and acts like an injector, drawing in air instead of water. The ashpan would habe to be made airtight, the door being provided for cleaning out only. It would also be necessary to arrange so that the steam jet was shut off when the firedoor was opened, otherwise the fire would blow out and scorch the driver. This could be done by fitting the steam cock close to the door and connecting it thereto, so that opening the door closed the cock. It would also be necessary 'to have a firedoor with no vent holes.

With regard to the firebars it is necessary to provide much greater air space than for coal, and also the bars themselves must be stouter to withstand the high temperature without burning out. A suitable size is bare in. thick with f to in. air space. Wrought iron is also a better material for coke firebars, because it does not fuse so readily as cast-iron, and, therefore, there is less tendency for the ash to adhere to the bars and form clinker.

From the foregoing remarks it will be evident that, with the present principal types of boilers, it is impossible to ol.tain really efficient results with coke fuel, and this is borne out by the experience of steam wagon owners. Until a suitable type of boiler is introduced, it will only be possible with such as loco type boilers, to use coke on very Loft journeys and then with much care and attention on the part of the driver. Of the two alternative fuels better results will be more easily obtained with bituminous coals than with coke. HEPHCESTUS.