1938 US suspensim system bounces bad

Page 82

Page 83

If you've noticed an error in this article please click here to report it so we can fix it.

Sandbach Engineering's latest weight-savi strategy is the adoption of torsion-bar-bog suspension, which is one of the lightest available. Bryan Jarvis puts it to the test

SANDBACH ENGINEERING enjoys many benefits by belonging to the enormous US engineering corporation Paccar Incorporated. One of them is the valuable interchange of information on development and proprietary designs within the group.

From this pool of engineering know-how, Sandbach has introduced an optional, torsion bar, bogie suspension for its Foden S106 6x4 tractive unit for use at 32 or 38 ton, for which type approval is expected in June. It is intended primarily for general road haulage application but can be employed on certain tipping operations which do not involve high centre of gravity loads or difficult site work.

This latest artic bogie suspension arrangement originates from a patent design which the Kenworth Truck Company first introduced in 1938 for on-highway application in America and has since been modified and improved in response to customer needs.

Sandbach claims that this type of suspension system is one of the lightest currently available, considering its maximum weight rating of 20 tonne (19.7 ton). Compared with the FF20 rubber suspension or parabolic taper leaf springs with telescopic dampers, the torsion bar arrangement reduces the tractive units overall unladen weight by 84kg (185 lb) which, when interpreted in terms of payload, becomes a marked saving.

The first production vehicle to be equipped with this system is the Foden S106 tractive unit with the Cummins NTE 350 216kW (290bhp) engine ordered by Roger Bettley of Sandbach. He will be carrying out an assessment of its performance, though having been in operation for many years at much higher maximum weights in the USA, Europe and the Middle East it is expected to be more than suitable at 38 tonnes on British roads.

Roger is well qualified to perform this valuable task having served a full apprenticeship with Fodens followed by several years in its experimental department as a fitter/tester before branching out as an operator. He previously ran an 595 Fleetmaster, which had parabolic leaf spring suspension.

Although it has only been in service for a few weeks, Roger is delighted with the smoother ride, whether laden or unladen, and feels the option justifies itself by virtue of its weight saving alone.

After driving his vehicle around the Middlewich, Sandbach area, and another similarly equipped experimental S106 artic, which was laden to maximum gross weight, I was inclined to agree that it did give a firm and well controlled ride, especially over some of the un dulating road surfaces in that area.

The cab ride remained very well balanced throughout the 40km (25-mile) drive especially when carrying out fast gear changes through the lower ratios. Rapid deceleration failed to produce any excessive dipping of the cab.

Acceleration and braking on sharp curves also failed to upset its smooth ride, while traction remained very positive at all times.

The basic principle of this type of suspension is that vertical axle movement caused by bumpy road surfaces is transferred to the bar with a twisting force which absorbs the shock effect on the vehicle frame and the freight carried.

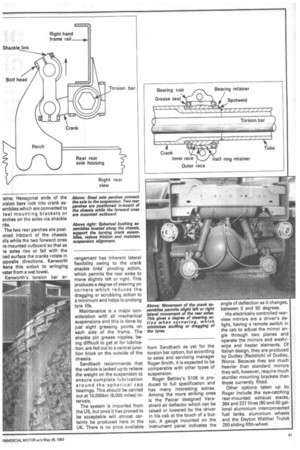

Kenworth's design consists of torsion bars secured, parallel to the chassis, with brackets at each end to distribute braking and twisting forces over the ame. Hexagonal ends of the )rsion bars lock into crank asemblies which are connected to teel mounting brackets or arches on the axles via shackle nks.

The two rear perches are posioned inboard of the chassis ails while the two forward ones re mounted outboard so that as le axles rise or fall with the bad surface the cranks rotate in ipposite directions. Kenworth kens this action to wringing vater from a wet towel.

Kenworth's torsion bar ar rangement has inherent lateral flexibility owing to the crank shackle links' pivoting action, which permits the rear axles to move slightly left or right. This produces a degree of steering on corners which reduces the dragging or scrubbing action to a minimum and helps to prolong tyre life.

Maintenance is a major consideration with all mechanical suspensions and this is done by just eight greasing points on each side of the frame. The shackle pin grease nipples, being difficult to get at for lubrication, are fed out to a central junction block on the outside of the chassis.

Sandbach recommends that the vehicle is jacked up to relieve the weight on the suspension to ensure complete lubrication around the spherical cap bearings. This should be carried out at 10,000km (6,000 miles) intervals.

The system is imported from the US, but once it has proved to be acceptable will almost certainly be produced here in the UK. There is no price available

from Sandbach as yet for the torsion bar option, but according to sales and servicing manager Roger Smith, it is expected to be comparable with other types of suspension.

Roger Bettley's S106 is produced to full specification and has many interesting extras. Among the more striking ones is the Paccar designed Varashield air deflector which can be raised or lowered by the driver in his cab at the touch of a button. A gauge mounted on the instrument panel indicates the angle of deflection as it changes, between 0 and 50 degrees.

His electrically controlled rearview mirrors are a driver's delight, having a remote switch in the cab to adjust the mirror angle through two planes and operate the mirrors and wash/wipe and heater elements. Of Italian design, they are produced by Dudley (Redditch) of Dudley, Worcs. Because they are much heavier than standard mirrors they will, however, require much sturdier mounting brackets than those currently fitted.

Other options taken up by Roger include the eye-catching rear-mounted exhaust stacks, 364 and 227 litres (80 and 50 gallons) aluminium interconnected fuel tanks, aluminium wheels and the Dayton Walther Trulok 250 sliding fifth-wheel.