Smooth newcomer

Page 69

Page 70

Page 71

If you've noticed an error in this article please click here to report it so we can fix it.

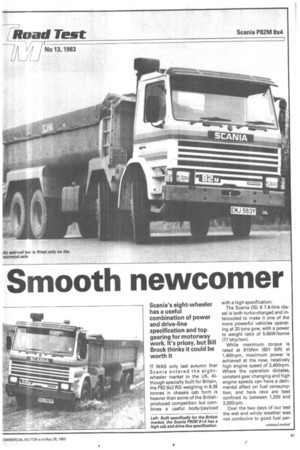

Scania's eight-wheeler has a useful combination of power and drive-line specification and top gearing for motorway work. It's pricey, but Bill Brock thinks it could be worth it

IT WAS only last autumn that Scania entered the eightwheeler market in the UK. Although specially built for Britain, the P82 8x2 RSi weighing in 8.38 tonnes in chassis cab form is heavier than some of the Britishproduced competition but combines a useful body/payload with a high specification.

The Scania DSI 8 7.8-litre diesel is both turbo-charged and intercooled to make it one of the more powerful vehicles operating at 30 tons gvw, with a power to weight ratio of 5.6kW/tonne (77 bhp/ton). While maximum torque is rated at 815Nm (601 Ibft) at 1,400rpm, maximum power is achieved at the now, relatively high engine speed of 2,400rpm. Where the operation dictates, constant gear changing and high engine speeds can have a detrimental effect on fuel consumption, and here revs are best confined to between 1,200 and 2,00Orpm.

Over the two days of our test the wet and windy weather was not conducive to good fuel per formance and it came as a small surprise that the final figure over CM's tough on/off-road route was not down below the 5.5mpg mark.

Engine revs do not make up all of the fuel consumption equation — a well matched gearbox and final ratio have an important part to play too. The choice of driveline includes a 10-speed splitter or, as fitted to the test vehicle, a 1 0-speed rangechange gearbox. Such multiplicity of gearing makes it all the easier to keep the engine churning at the optimum speed irrespective of road speed. Rear drive incorporates two Scania singlereduction spiral bevel gear axles with pneumatically operated inter-axle and cross-axle differen-. tial locks for off-road work where the going gets very sticky.

The four-spring non-reactive rear bogie is dampened by double-acting telescopic shock dampers on both axles, while each spring is made up of eight leafs and collectively allows as much as 16 degrees of bogie ar ticulations. A rear stabiliser bar is fitted to the rearmost axle to restrict body roll.

The number of greasing points included in the design of the rear suspension must make a good case for an automatic lubrication system. The design is reminiscent of an earlier Leyland model but the bushes used here are threaded, which effectively doubles the surface area and reduces the wear rate.

Both front axles are of 1-section rigid beam construction, each with a capacity of seven tonnes. Steering on the frontaxle incorporates a power-assisted steering box connected with a hydraulic ram and attached to the draglink of the second axle.

Air tanks and batteries are grouped together on the outside of the chassis. Our test vehicle had brake anti-freeze protection. Despite the advances in air drying equipment, alcohol injection is still a legal requirement in Sweden.

The all-steel Scania P day cab is generously equipped. Its ventilation system is claimed to filter air so finely that even pollen is prevented from entering the cab.

On the nearside, the passenger window is electronically operated while electrical heating extends to the driver's seat and rear mirrors. The halogen headlamps can be reset from within the cab to comply with load condition.

Instrumentation incorporates all of the essential gauges for air pressure, oil pressure engine temperature and fuel level and a host of warning lights, some of which double up on the gauges.

The layout is generally good but contains a conflict of styling with round tachograph and square tachometer. All of the controls are within easy reach, and the steering wheel adjusts for height and rake.

Control for the power take-off operating the tipping gear is located between the door and driving seat. Despite my initial supposition that it was the park brake lever, it is ideally positioned, though the pipework is vulnerable to careless feet. Thick rubber mats cover the floor wells, which extend to the door openings, thus cleaning is easy.

Mounted to the rear of the cab is its 15cum (20cuyd)Semsonlite all-welded high-tensile alloy body which is equipped with an tegral ladder, a close-fitting fly met and Edbro DS16 single ant-ram tipping gear.

At the Mira test track we cared out the specific meairements of braking acceleraan and hill restarting before loving on to CM's on/off road tst route.

On a wet track all of the rheels could be made to lock rith ease but the vehicle topped in a straight line without ny pull on the steering and only small amount of suspension ip.

A short lever and precise lovement of the gearshift aided le swift acceleration through the 10 gears of the range change box.

Minimal delay in the release of the park brake and use of the deep 13.51 to 1 crawler gear permitted an easy restart on a wet 1 in 4 gradient. The standard splitter box is specified with a higher 9.89 to 1 low ratio.

The P cab's entrance is deceptively high but entry is made easy with three well-placed steps and grab handles. Once settled into the firmly upholstered air suspension seat, I could easily see the switches and instrumentation. With power switched on, all gauge needles swing inwards simultaneously so that any malfunction is apparent at a glance.

With the engine running, the heavily insulated cover over the engine cowl keeps the sound of noise at a very low level in all running conditions.

Despite having to make several starts from rest on the most difficult part of the off-road section, due in part to our unfamiliarity with the vehicle, second gear was the lowest ratio needed at any time.

Once again on the move, it was possible to skip gears in the lower part of the box and still maintain engine speed within the most economical sector of the rev range. Gearchanging is, however, not an operation to be rushed even though the synchromesh box makes double declutching an obsolete skill. Positive engagement and light clutch-pedal effort contribute much to the balanced performance of the vehicle.

Although the engine readily lugged down to around 1,100rpm, most of the running was at above maximum torque speeds.

Steering was light but the wheel gave a good feed back of the road conditions and even on loose rutted corners we maintained a steered course well.

Over the metalled sections the brakes responded well to give an impressive rate of deceleration when called upon to do so. Bad weather and wet tyres meant an unsatisfactory read-out from the rolling road test bed provided by Waitrose's Bracknell workshop. Traction was lost prematurely because of water in the tyre tread on a slow rolling drum.

Journey times around the route were slowed on several occasions by untypical traffic, which may also have raised the fuel consumption a couple of points.

The P82 8x4 provides a good mix of power and drive-line specification for hard off-road work combined with the top gearing for motorway running. Priced at £35,000, it is a pricey vehicle for a 30-ton tipper chassis, but with a smooth performance and highly comfortable working environment it provides a good deal of value for money.