If your tipper topple twist, and it's tip tor

Page 38

Page 39

Page 40

If you've noticed an error in this article please click here to report it so we can fix it.

The bends are an occupational hazard in this line of work. Graham Montgomerie tips you the wink and gets you back on the straight and narrow

GRAVITY being what it is, an unfortunate fact of life is that tippers can fall over during tipping. As the ground surface is rarely level or smooth, the problem of stability is obviously a big one.

In this special tipper issue of CM we report on the methods used to straighten bent chassis and bodywork at the premises of Chassis Repairs Ltd at 106-108 Leeds Road, Wakefield, where director David Gray took us through the process with a Magirus Deutz eight-wheeler as an example.

Tippers (in particular eight

wheelers) account for the 'arc part of the Chassis Repairs bt. ness. Nearly all of these are for straightening the chassis a body after the vehicle has fail over during tipping — repairs a result of traffic accidents rare.

The first thing that happens that Chassis Repairs get a pho call along the lines of "It's be How much is it going to cost David Gray will then go and lo at the vehicle to decide whet it can be dealt with by fellc director Ted Pearce and his rr bile Volkswagon LT31 workshi or whether it needs to brought in to the Leeds Ro, premises.

David Gray uses the anala of looking along a rifle barrel gain an impression of hc straight the vehicle is. He is great believer in the human e' as "a very economical laser arguing that it is possible to g carried away with a preponcic ance of equipment. Having sa that, Chassis Repairs does u! some highly expensive equi ment, mainly from Bee-Line, f, its straightening work.

Although standing behind tt chassis and looking along th main rails gives an excellent i dication of how bent the frarr is, this is not always possible bodywork and ancillary equii ment may be in the way. So sel centering gauges are use which effectively transfer centre line of the vehicle 1 outside the chassis wher pointers on the end of

IIgauges can be lined up.

Straight edges about 12ft Ion can also be used to show up an distortion; when placed acroE the chassis, they magnify th discrepancy.

There is certainly more t chassis straightening than jur "pressing it crudely in one c two places," as David Gray pi it. Chassis can distort upward! downwards, sideways, diags nally and any combinatio thereof, and it is illogical to bs lieve it will distort in one plan only.

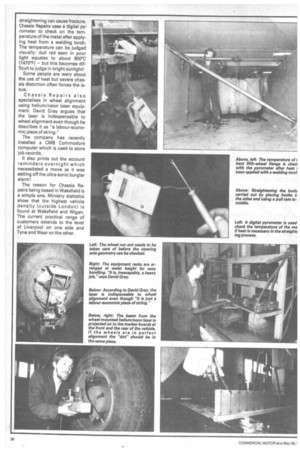

Because of modern equir ment like Bee-Line the art E chassis straightening has alma become an act of standin around while somebody pressE a button and hydraulic powE taking over. This is not to say, however, that experience counts for nothing.

The hydraulic rams act against the twisted chassis which is anchored to the three and a half tons of structural steel forming the base of the Bee-Line equipment. The chassis is twisted beyond the neutral point and then allowed to return to the unloaded position. If it is still twisted, the process is repeated. The experience comes in by keeping down to a minimum the number of times the reverse twisting is used.

With very stiff frames the chassis does not need to be twisted too far past, but long wheelbase rigids tend to wind up like a spring. David Gray summed up the process by saying: "The art lies in getting the equipment in the right place and knowing how much deflection is necessary to get the frame straight again."

Heat is sometimes necessary to remove local buckling as cold straightening can cause fracture. Chassis Repairs uses a digital pyrometer to check on the temperature of the metal after applying heat from a welding torch. The temperature can be judged visually: dull red seen in poor light equates to about 800°C (1470°F) — but this becomes difficult to judge in bright sunlight!

Some people are wary about the use of heat but severe chassis distortion often forces the issue.

Chassis Repairs also specialises in wheel alignment using helium/neon laser equipment. David Gray argues that the laser is indespensable to wheel alignment even though he describes it as "a labour-economic piece of string."

The company has recently installed a CMB Commodore computer which is used to store job records.

It also prints out the account reminders overnight which necessitated a move as it was setting off the ultra-sonic burglar alarm!

The reason for Chassis Repairs being based in Wakefield is a simple one. Ministry statistics show that the highest vehicle density (outside London) is found at Wakefield and Wigan. The current practical range of customers extends to the level of Liverpool on one side and Tyne and Wear on the other.