Tender at 13.5 tons gvw

Page 46

Page 47

Page 48

If you've noticed an error in this article please click here to report it so we can fix it.

by Graham Montgomerie

AN air crash happens so frighteningly fast, rescue services have to count the seconds — usually because the risk of fire is so high. That's why an airfield crash tender has to be designed to get to a fire quickly — and over the worst terrain imaginable.

I think the SD/Carmichael, with its ride and handling characteristics fits the bill.

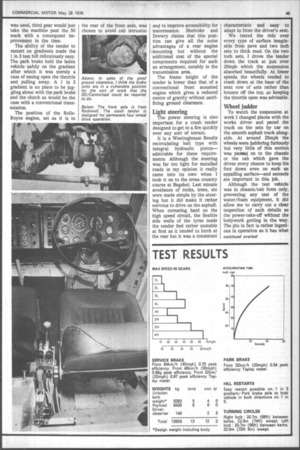

This airfield crash tender, developed jointly between Shelvoke and Drewry Ltd and Carmichael and Sons Ltd, is a 4 x 4 design with gvw of 13.5 tons. The initial requirement was for a fire-fighting vehicle with a high performance capability, carrying a supply of water and foam liquid. Our test of the tender in chassis/cab form showed it to be a highly manoeuvrable and rapid machine which performed extremely well in all areas during our road test. High specification As you would expect with this type of vehicle, performance is all-important and this is taken care of by using a straight-eight Rolls-Royce petrol engine which produces a hefty 175kw (235bhp) at 4000rpm. For a gvw of 13.5 tons this enabled the tender to reach the 50 mark in just under 43 seconds.

An Allison automatic gearbox with four forward speeds is coupled to a ZF transfer box with ratios of 1:1 and 1:6 to 1 driving to both Rockwell axles. In high range the maximum speed of the SD/Carmichael was 104km/h (64mph) with the equivalent maximum in the low range being 65km/h (41mph).

Even allowing for the comfortable power-to-weight ratio of 12.8kw/tonne (17.4bhp/ton) the vehicle returned some incredible acceleration figures at the MVEE testing ground at Chobham. In fact, I experimented with the gearbox quite a lot on this part of the test because if the Allison was left to its own devices it changed up at inconvenient times as far as timing was concerned.

For example, if left in "drive" the gearbox would change into fourth gear at around 47mph with the result that several seconds were added to the 0-50 time. If the transmission hold mechanism was used, third gear would just take the machine past the 50 mark with a consequent improvement in the time.

The ability of the tender to restart on gradients made the 1 in 3 test hill ridiculously easy. The park brake held the laden vehicle safely on the gradient after which it was merely a case of easing open the throttle and pulling away. A 1 in 3 gradient is no place to be juggling about with the park brake and the clutch as would be the case with a conventional transmission.

The position of the RollsRoyce engine, set as it is to the rear of the front axle, was chosen to avoid cab intrusion and to improve accessibility for maintenance. Shelvoke and Drewry claims that this position can give all the noise advantages of a rear engine mounting but without the additional cost of the special components required for such an arrangement, notably in the transmission area.

The frame height of the tender is lower than that of a conventional front mounted engine which gives a reduced centre of gravity without sacrificing ground clearance.

Light steering

The power steering is also important for a crash tender designed to get to a fire quickly over any sort of terrain.

It is a Westinghouse Bendix recirculating ball type with integral hydraulic piston— admirable for these requirements. Although the steering was far too light for metalled roads in my opinion it really came into •its own when I took it on to the cross country course at Bagshot. Last minute avoidance of rocks, trees, etc were made simple by the steering but it did make it rather nervous to drive on the asphalt. When cornering hard on the high speed circuit, the flexible side walls of the tyres made the tender feel rather unstable at first as it tended to lurch at the rear but it was a consistent characteristic and easy to adapt to from the driver's seat.

We tested the ride over every type of surface imaginable from pave and two inch sets to thick mud. On the two inch sets, I drove the tender down the track at just over 20mph which the suspension absorbed beautifully. At lower speeds the wheels tended to crash down at the base of the next row of sets rather than bounce off the top, so keeping the throttle open was advisable.

Wheel judder

To watch the suspension at work I changed places with the works driver and paced the truck on the sets by car on the smooth asphalt track alongside. At around 25mph the wheels were juddering furiously but very little of this motion was passed on to the chassis or the cab which gave the driver every chance to keep his foot down even on such an appalling surface—and seconds are important in this job.

Although the test vehicle was in chassis/cab form only, preventing any test of the water/foam equipment, it did allow me to carry out a clear inspection of such details as the power-take-off without the bodywork getting in the way. The pto in fact is rather ingenious in operation as it has what SD call "a foolproof device" for engaging. The first motion of the control button in the cab opens an air valve which supplies air to the pto air clutch which then drives the pump shaft. The completed movement of the control adjusts the engine throttle to the correct pumping speed which is maintained by a constant speed governor. On shutting down the cycle is reversed.

The list price for the chassis/ cab is £20,500. Because of the large variety in customer requirements in terms of bodywork and equipment, it is impossible to quote a "standard" price for a vehicle.