Liquid Sulphur Now Carried By Road

Page 58

If you've noticed an error in this article please click here to report it so we can fix it.

Successful Research Overcomes Difficulties Associated With the Storage and Transport of Nearly Pure Sulphur in Liquid Form

u

practice to make bulk deliveries of sulphur from the Shell chemical plant at Stanlow, Cheshire, in solid form, but now a specially built tanker has been introduced for transporting the sulphur in liquid state. The sulphur produced at Stanlow has a degree of purity of nearly 100 per cent., and when this is allowed to cool it, of course, becomes solid. In this form it has to be broken up before it can be transported. , No matter how carefully the work of solidification is done, the substance, when ultimately broken down and transported, is liable to become contaminated either by moisture or extraneous matter, which leads to subsequent processing difficulties. Dust particles may also blow about and find their way on to nearby equipment to cause corrosion.

The solution of these problems was to carry the sulphur in liquid form and to keep it in that condition up to the time it was actually being consumed.

Before this could be done, however, a number of interesting technical difficulties had to be overcome, not only at the production point, but in the design of the transporting tank and in the customer's storage . plant.

Sulphur is produced at Stanlow by burning 1-12S in a plant based on the Claus kiln process, and although the level of conversion is high, traces of HS are present in the sulphur product. This could give rise to the deposition of pyrophoric iron on the inner surfaces of the storage tanks.

To prevent the spontaneous ignition of this pyrophoric iron, with the consequent risks of tank explosions, an inert-gas blanket must be maintained over the surface of the sulphur. These precautions apply to the two 180-ton mild-steel storage tanks at Stanlow. which are lagged and steam heated to maintain the temperature of the contents within limits of 1400-150° C.

B24

To overcome the problem presented by the deposition of pyrophoric iron on the inner surfaces of the mild-steel tank used on the transport vehicle, its inner surface was treated by an aluminium metallizing process; and as there were no combustion problems to contend with, it was possible to use compressed air to discharge the contents.

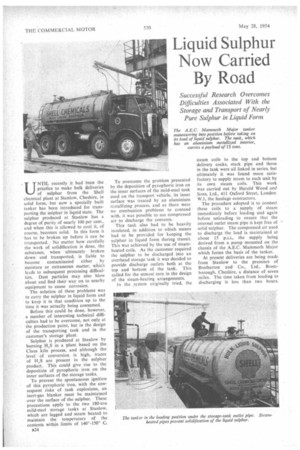

This tank also had to be heavily in3ulated, in addition to which means had to be provided for keeping the sulphur in liquid form during transit. This was achieved by the use of steamheated coils. As the customer required the sulphur to be discharged into an overhead storage tank it was decided to provide discharge outlets both at the top and bottom of the tank. This called for the utmost care in the design of the steam-heating arrangements.

In the system originally tried, the steam coils to the top and bottom delivery cocks, stack pipe and those in the tank were all linked in series, but ultimately it was found more satisfactory to supply steam to each unit by its own steam coils. This work was carried out by Harold Wood and Sons, Ltd., 411 Oxford Street, London W.1, the haulage contractors.

The procedure adopted is to connect these coils to a supply of steam immediately before loading and again before unloading to ensure that the internal outlet steam pipe is kept free of solid sulphur. The compressed air used to discharge the load is maintained at about 15 p.s.i., the supply being derived from a pump mounted on the chassis of the A.E.C. Mammoth Major which forms the basis of the tanker.

At present deliveries are being made from Stanlow to the premises of Brotherton and Co., Ltd., Bromborough, Cheshire, a distance of seven miles. The time taken from loading to discharging is less than two hours.