Minister Opens M.I.R.A.

Page 47

If you've noticed an error in this article please click here to report it so we can fix it.

Proving Ground

New Centre for Road Vehicle Research Combines Laboratory Facilities with Proving Ground where Overseas Conditions can be Reproduced LAST Friday was a great day in the history of the Motor Industry Research Association. Mr. A. T. Lennox-Boyd, Minister of Transport, formally opened the Association's new laboratories and the proving ground at Lindley, Northants. A feature Of the proceedings was a drive-past by representative British vehicles, which were afterwards available for inspection and demonstration.

Construction of the proving ground began in 1949, and so far £500,000 has been spent on the ground and laboratories. The site provides the finest test facilities for extreme conditions in Europe and occupies 650 acres.

These facilities are available for use by member companies day and night h e whole year round. Although no ;eparate figures have been published to h ow the number of hours that commer;ial vehicles alone have spent on the rack, 15.286 vehicle-hours of testing vere recorded for 1953 and that figure nay be doubled this year.

The laboratories make provision for esearch into all aspects of vehicle con truction and are continually in use, 4achines have been built to examine le bending and torsional fatigue length of crankshafts, the strength of ear teeth and the properties of brake tcings, with emphasis on fade and fueal. Metallurgical and chemical .boratories are available.

The engine laboratory has eight test tys, the walls and ceilings of which e covered with sound-absorbing aterials. In this laboratory crankshaft ads under running conditions may be easured, using strain gauges and thode-ray oscillographs, and much ne is being devoted to the use of low. icosity lubricants in oil engines.

By using S.A.E. 5 W. oil in a 10-litre engine in place of S.A.E. 50, a gain 5 b.h.p. has been achieved, although consumption has risen from 2,600 p.g. to 830 m.p.g. The effect which : use of thin oil i has on engine wear being determined from vehicles in ual service.

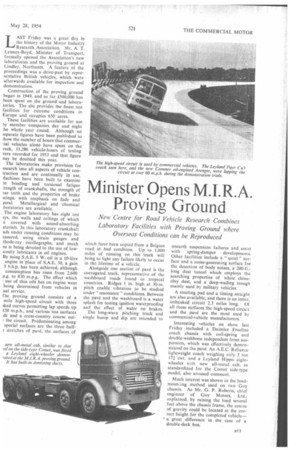

file proving ground consists of a -mile high-speed circuit with three kited curves permitting lap speeds up 150 m.p.h., and various test surfaces de and a cross-country course out.; the circuit. Predominating among special surfaces arc the three half! stretches of pave,' the surfaces of which have been copied from a Belgian road in bad condition. Up to 1,000 miles of running on this track will bring to light any failure likely to occur in the lifetime of a vehicle.

Alongside one section of pave is the corrugated track, representative of the washboard roads found in tropical countries. Ridges 1 in. high at 30-in. pitch enable vibration to be studied under " resonance" conditions. Between the pave and the washboard is a water splash for testing ignition waterproofing and the effect of water on brakes.

The long-wave pitching track and single bump and dip are intended to unearth suspension failures and assist with spring-damper developments. Other facilities include a " quiet " surface and a noise-generating surface for the detection of body noises, a 200-ft.long dust tunnel which employs the searching properties of white chinaclay dust, and a deep-wading trough mainly used by military vehicles.

A steering pad and a timing straight are also available, and there is an inner, unbanked circuit 2.3 miles long. Of all these surfaces the high-speed circuit and the pave are the most used by commercial-vehicle manufacturers.

Interesting vehicles on show last Friday included a Daimler Freeline coach chassis with coil-spring and double-wishbone independent front suspension, which was effectively demonstrated on the pave. An A.E.C. Reliance lightweight coach weighing only 5 ton 171 cwt. and a Leyland Hippo eightwheeler with new all-metal cab, as standardized for the Comet side-type model, also aroused comment.

Much interest was shown in the loadmounzing method used on two Guy chassis. As Mr. G. P. Roberts, chief engineer of Guy Motors, Ltd., explained, by raising the load several feet above the chassis frame, the centre of gravity could be located at the correct height for the completed vehicle, a great difference in the case of a double-deck bus.