Containing tyre costs

Page 32

Page 33

If you've noticed an error in this article please click here to report it so we can fix it.

by Tim Hoare

4E PRICE of a typical 22.5 inch steelaced radial tyre is now approaching 10 and only the most ardent of 'flutists would dare predict that the end of price increases is not going to Intinue.

Tyre running costs for a 32-ton artic ere calculated to be 2.37 pence per mile atal vehicle running costs 22.07 pence tr mile) at the time C s 1974 tables of nrating costs were compiled. For a 16nner tyre costs were reckoned to be 05 pence per mile but since the tables ere published, of course, the purchase ice of tyres has increased considerfly. It is, therefore, even more wortant that tyres are removed from .e category of fit 'ern and forget 'em amponents.

Factors which will greatly reduce the 'e of a tyre invariably centre around Le vehicle's suspension or steering — ith the trouble often being at the losite end of the chassis from the badly orn tyre.

'atch out

Mixing different sizes in twin isenablies or bogies will obviously [feet the wear rate but mixing tyres of le same size but of a different specificaon (textile and steel braced radials for am pie) will have the same detrimental fect.. Under-inflation, initially resultig in a very rapid build up of heat ithin the tyre will in extreme circum,ances cause tread to break up, while ver-inflation will result in excessive wear in the centre section of the tread area of the tyre. It pays therefore to keep a careful watch on tyre pressures, specially between light and loaded running conditions. Most of the major tyre distributors provide a complete tyre monitoring and changing service for operators under contract and it is certainly worth while looking into having a comprehensive contract arrangement. By looking at the condition of the tyres the engineer will often be able to spot suspension or steering faults which could be another advantage for having a contract.

It must also be remembered that casings which are suitable for remoulding are becoming more and more in demand commanding up to £15 per casing. Ways of actually extending the life of a tyre beyond its first life are restricted to recutting (or regrooving) and remoulding. It is not permissible to recut tyres fitted to goods vehicles of less than 2,540 kg (2.5 tons) unladen weight or less than 3,050kg (3 tons) if their wheel diameter is less than 405rrun (16 in). Passenger vehicles of less than 2,540 kg (2.5 tons) unladen weight or less than 3,050kg (3 tons) if the wheel diameter is less than 405mm (16 in), and passenger vehicles of less than 2,540 kg (2.5 tons) ulw or less than 3,050kg (3 tons) if designed to carry no more than seven passengers excluding driver are also not permitted to be fitted with recut tyres.

The vast proportion of hauliers, how • ever, can take advantage of recutting and extend the life of a tyre by between 10 and 20 per cent, and Michelin, for example, sees no reason why its X range of tyres cannot, with careful use, be regrooved, remoulded and then regrooved again.

Many larger operators carry out the regrooving process themselves employing a full-time tyre fitter who has been trained to do recutting, and smaller hauliers can get the same benefits by having a local tyre distributor do the work for them. We recently followed through the regrooving of a tyre at the new Birmingham depot of Natio' Tyre Services Ltd, a subsidiary Dunlop.

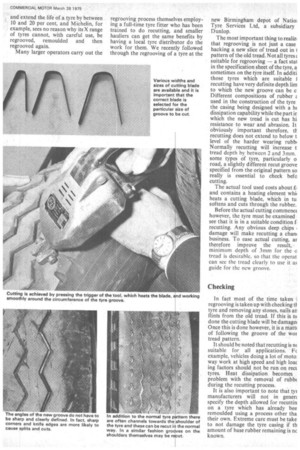

The most important thing to realizi that regrooving is not just a case hacking a new slice of tread out in pattern of the old tread. Not all tyres suitable for regrooving — a fact sta.' in the specification sheet of the tyre, a sometimes on the tyre itself. In add iti those tyres which are suitable i recutting have very definite depth lim to which the new groove can be c Different compositions of rubber used in the construction of the tyre the casing being designed with a h( dissipation capability while the part it which the new tread is cut has hi resistance to wear and abrasion. It obviously important therefore, tf. recutting does not extend to below t level of the harder wearing rubbi Normally recutting will increase t tread depth by between 2 and 3mm. some types of tyre, particularly o road, a slightly different recut groove specified from the original pattern so really is essential to check befo cutting.

The actual tool used costs about £. and contains a heating element whil heats a cutting blade, which in tu softens and cuts through the rubber.

Before the actual cutting commenc( however, the tyre must be examined see that it is in a suitable condition f recutting. Any obvious deep chips damage will make recutting a chart( business. To ease actual cutting, at therefore improve the result, minimum depth of 3mm for the (3 tread is desirable, so that the operat can see the tread clearly to use it as guide for the new groove.

Checking In fact most of the time taken regrooving is taken up with checking ti tyre and removing any stones, nails an flints from the old tread. If this is n( done the cutting blade will be damage( Once this is done however, it is a matt( of following the groove of the wor tread pattern.

It should be noted that recutting is ry suitable for all applications. Fc example, vehicles doing a lot of moto way work at high speed and high loac ing factors should not be run on rect tyres. Heat dissipation becomes problem with the removal of rubbt during the recutting process.

It is also important to note that tyr manufacturers will not in genen specify the depth allowed for recuttin on a tyre which has already bee remoulded using a process other tha their own. Extreme care must be take to not damage the tyre casing if th amount of' base rubber remaining is nc known.