A lightweight 24-ton tractive unit

Page 66

Page 67

If you've noticed an error in this article please click here to report it so we can fix it.

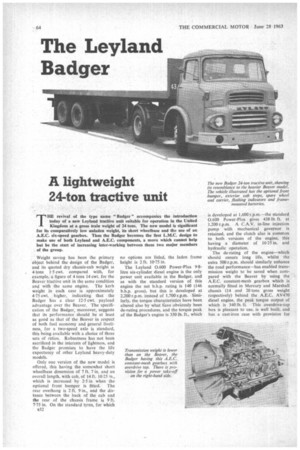

THE revival of the type name " Badger " accompanies the introduction today of a new Leyland tractive unit suitable for operation in the United Kingdom at a gross train weight of 24 tons. The new model is significant for its comparatively low unladen weight, its short wheelbase and the use of an A.E.C. six-speed gearbox. Thus the Badger becomes the first L.M.C. design to make use of both Leyland and A.E.C. components, a move which cannot help but be the start of increasing inter-working between these two major members of the group.

Weight saving has been the primary object behind the design of the Badger, and its quoted dry chassis-cab weight is 4 tons 1.5 cwt. compared with, for example, a figure of 4 tons 14 cwt. for the Beaver tractive unit in the same condition and with the same engine. The kerb weight in each case is approximately 4-75 cwt. higher, indicating that the Badger has a clear 12-5 cwt. payload advantage over the Beaver. The specification of the Badger, moreover, suggests that its performance should be at least as good as that of the Beaver in respect of both fuel economy and general liveliness, for a two-speed axle is standard, this being available with a choice of three sets of ratios. Robustness has not been sacrificed in the interests of lightness, and the Badger promises to have the life expectancy of other Leyland heavy-duty models.

Only one version of the new model is offered, this having the somewhat short wheelbase dimension of 7 ft. 7 in. and an overall length, with cab, of 14 ft. 10-25 in., which is increased by 2.5 in when the optional front bumper is fitted. The rear overhang is 2 ft. 9 in., and the distance between the back of the cab and the rear of the chassis frame is 9 ft. 7-75 in. On the standard tyres, for which n32 no options are listed, the laden frame height is 2 ft. 10-75 in.

The Leyland 0.600 Power-Plus 9-8litre six-cylinder diesel engine is the only power unit available in the Badger, and as with the standard version of this engine the net b.h.p. rating is 140 (146 b.h.p. gross), but this is developed at 2,200 r.p.m. instead of 1,700 r.p.m. Similarly, the torque characteristics have been altered also by what gave obviously been de-rating procedures, and the torque peak of the Badger's engine is 350 lb. ft., which is developed at 1,600 r.p.m.—the standard 0.600 Power-Plus gives 438 lb, ft. at 1,200 r.p.m. A C.A.V. in-line injection pump with mechanical governor is retained, and the clutch also is common to both versions of the engine, this having a diameter of 16-25 in. and hydraulic operation.

The de-rating of the engine—which should ensure long life, whilst the extra 500 r.p.m. should similarly enhance the road performance—has enabled transmission weight to be saved when compared with the Beaver by using the A.E.C. constant-mesh gearbox which is normally fitted in Mercury and Marshall chassis (14 and 20 tons gross weight respectively) behind the A.E.C. AV470 diesel engine, the peak torque output of which is 340 lb. ft. This overdrive-top box is pleasant to use, is well built, and has a cast-iron case with provision for

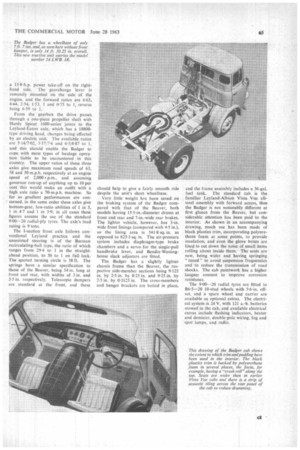

a 15-8-h.p. power take-off on the righthand side. The gcarchange lever is remotely mounted on the side of the engine, and the forward ratios are 6-63, 4-44, 2-54, 1-53, 1 and 0-75 to I, reverse being 6.59 to I.

From the gearbox the drive passes through a one-piece propeller shaft with Hardy Spicer 1600-series joints to the Leyland-Eaton axle, which has a 18800type driving bead, changes being effected by an electric unit. The available ratios are 5-14/7-02, 5-57/7.6 and 6-5/8.87 to I, and this should enable the Badger to cope with most types of haulage operation liable to be encountered in this country. The upper ratios of these three axles give maximum road speeds of 63, 58 and 50 m.p.h. respectively at an engine speed of 2,000 r.p.m., and assuming governor run-up of anything up to 10 per cent this would make an outfit with a high axle ratio a 70-m.p.h. machine. So far as gradient performances are concerned, in the same order these axles give bottom-gear, low-ratio abilities of I in 5, 1 in 4-7 and 1 in 3-9; in all cases these figures assume the use of the standard 9-00-20 radial-ply tyres. The axle's load rating is 9 tons.

The 1-section front axle follows conventional Leyland practice and the unassisted steering is of the Burman recirculating-ball type, the ratio of which ranges from 29.4 to I in the straightahead position, to 50 to I on full lock. The quoted turning circle is 38 ft. The springs have a similar specification to those of the Beaver, being 54 in. long at front and rear, with widths of 3 in. and 3.5 in. respectively. Telescopic dampers are standard at the front, and these

should help to give a fairly smooth ride despite the unit's short wheelbase.

Very little weight has been saved on the braking system of the Badger compared with that of the Beaver, both models having I5-5-in.-diameter drums at front and rear and 7-in.-wide rear brakes. The lighter vehicle, however, has 3-in. wide front linings (compared with 4.5 in.), so the lining area is 541-8 sq. in. as opposed to 623.3 sq. in. The air-pressure system includes diaphragm-type brake chambers and a servo for the single-pull handbrake lever, and Bendix-Westinghouse slack adjusters are fitted.

The Badger has a slightly lighter chassis frame than the Beaver, the respective side-member sections being 9.125 in. by 2.5 in. by 0.25 in. and 9-25 in. by 2-5 in. by 0.3125 in. The cross-members and hanger brackets are bolted in place, and the frame assembly includes a 36-gal. fuel tank. The standard cab is the familiar Leyland-Albion Vista Vuc allsteel assembly with forward access, thus the Badger is not noticeably different at first glance from the Beaver, but considerable attention has been paid to the interior. As shown in an accompanying drawing, much use has been made of black plastics trim, incorporating polyurethane foam at some points, to provide insulation, and even the glove boxes are lined to cut down the noise of small items rolling about inside them. The seats are new, being wider and having springing " tuned" to avoid suspension frequencies and to reduce the transmission of road shocks. The cab paintwork has a higher lacquer content to improve corrosion resistance.

The 9.00-20 radial tyres are fitted to B6-5-20 10-stud wheels with 5.6-in. offset, and a spare wheel and carrier are available as optkmal extras. The electrical system is 24V, with 121 a.-h. batteries stowed in the cab, and available electrical extras include flashing indicators, heater and demister, double-pole wiring, fog and spot lamps, and radio.