Shot-blast Process as Aid to Maintenance

Page 35

If you've noticed an error in this article please click here to report it so we can fix it.

AN important feature in repair and maintenance work to-day is that of time-saving, and if this can be achieved, together with an improvement in the actual results obtained, .it must be conceded that the acquisition of equipment such as will bring about this end is worthy of serious thought.

The modern method of cleaning-up welded constructions, the descaling of corroded engine valves, the removal of carbon from a cylinder head, and many other operations of a similar character are by means of theshot-blasting process, in which air pressure is utilized.

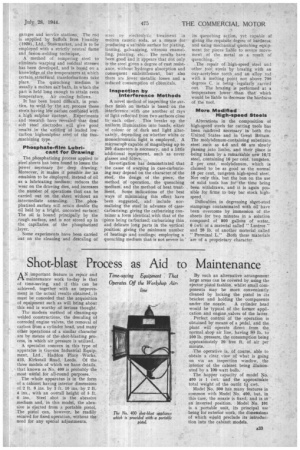

A specialist concern in this type of apparatus is Guyson Industrial Equipment, Ltd., Haddon Place Works, 423, Kirkstall Road, Leeds. Of the. three models of which we have details, that known as No. 400 is probably the most useful for all-round purposes. .

The whole apparatus is in the form of a cabinet having interior dimensions of 2 ft. 8 ins. by 1 ft. 10 ins.. by 2 ft. 4 ins., with an overall height of 5 ft. 6 ins. Steel shot is the abrasive medium and, in this model, the abrasive is ejected from• a portable pistol. The pistol can, however, be readily secured for fixed operation, without the need for any special adjustments.

By such an alternative arrangement large areas can be covered by using the ejector pistol fashion, whilst small components may be more, conveniently cleaned by locking the pistol in as bracket and holding the components

under the nozzle. A cylinder head would be typical of the former application and engine valves of the latter.

Perfect control of the operation is obtained by means of a pedal, and the plant will operate direct from the normal shop air line, having 80 lb. to 100 lb. pressure, the consumption being approximately 20 free ft. of air per minute.

The operative is, of course, able to obtain a clear view of what is going on via an inspection wind'ow, the interior' of the cabinet being illuminated by a 100 watt bulb.

The hopper capacity of model No. 400 is 1 cwt. and the approxim'ate total weight of the outfit cwt.

Model No. 300 has many features in common with Model No. 400, but, in this case, the nozzle is fixed, and is in an inverted position. Model No. 101 is a .portable unit, its principal use being for exterior work, the dimensions of which would preclude its introduction into the cabinet models.