ROAD TRANSPORT PROVES ESSENTIAL CANIN ■ 1G INDUSTRY

Page 50

Page 51

Page 52

If you've noticed an error in this article please click here to report it so we can fix it.

HAULAGE in the canning industry is now at its peak of activity, and it will continue to be busy for some months to come. If we add the information that there is more opportunity for small hauliers in connection with the canning industry than in any other, with the possible exception of farming, the importance of our opening paragraph will be adequately appreciated.

It may be well, in the first place, to indicate the variety of work which becomes available to hauliers in this connection. The most obvious phase is the conveyance of the fruit, vegetables and other produce from the source to the canning factories.

Next in importance is the haulage Of the cans from the manufacturer. Usually, the containers are packed in strawboard cartons and the assistance of the road naulier is required to bring to the can and carton makers the raw materials for their products, namely, the strawboard and the tin-plate. In this connection, we may remind readers that, recently, in our weekly feature, "Where to Find Haulage Business," reference was made to the fact that the tin-plate factories in the Swansea area were already feeling the effects of the first stirrings of activity in the canning factories.

Finally, there is the haulage work involved in the conveyance of the completed product, the canned produce, from the factory, first to the principal centres of distribution and then from those centres to wholesalers and retailers throughout the country.

The industry is, too, one which is bound to thrive. The writer, prior to his tour of the factories, was prejudiced against tinned foods. His opposition was, however, turned to enthusiasm as the result of his investigations. The meticulous care with which the produce is examined before it is passed as suitable for canning, the scrupulous cleanliness which is observed throughout the various processes in the factory and the exigencies of the methods of inspection, have convinced him of the value of tinned foods, as compared with unpreserved products. It is, therefore, not surprising that the+ demand for tinned food is steadily growing.

,The briefest reference to statistics will serve to inolleace the possibilities that the canning industry B32

offers in the way of work for hauliers. Perhaps the• most striking figures are those relating to the tin-plate industry itself. Its output has grown from 7,840,000 tons in 1927 to 112,000,000 tons in 1932. In 1929, 16,000,000 cans were manufactured, 83,000,000 in 1931 and 100,000,000 last year. That total is expected considerably to be surpassed this season.

There are now 84 canning factories in England and Wales, 30 of which corn menced operations only last year. They' are, too, well distributed throughout the country, there being one or more in each of the following counties :—Worcestershire, Middlesex, Lincolnshire, Herefordshire, Essex, Kent, Cambridgeshire, Norfolk, Suffolk, Lancashire, Gloucestershire, Cheshire, Warwickshire, Hampshire, Wiltshire, Yorkshire, Derbyshire, Buckinghamshire, Northamptonshire and Sussex. In addition, there are factories in Scotland and Wales. New factories are springing up in centres hitherto untried. Here, again, we should take the opportunity of referring to our feature, "Where to Find Haulage Business," in which readers have been notified, within recent months, of projects to build factories at Bridgnorth, Boston, Retford, Liverpool and Wisbech.

A big new project has as its objective the building of no fewer than 40 chicken-canning factories, evenly distributed over the country. The National Canning Co., Ltd., one of several big combines in the industry, is about to establish a chain of factories around the coast for the canning of fish.

Wherever there are factories, there can be found not merely assurance of haulage, but, with a little investigation, information as to the amount of work that is likely to be available, for contracts are usually made in advance with farmers and fruit growers. As an example, United Canners, Ltd., in connection with its factories at Louth and Boston, contracted with the local farmers to take, this season, the crops of peas from 3,000 acres.

It seems that almost anything in the way of foodstuff may successfully be preserved in tins. The principal items in a long schedule are, of course, fruit and vegetables, but fish, poultry and boned hams are becoming increasingly popular when canned. The vegetables include peas and beans, new potatoes, young English carrots, celery, beetroot, turnips, spinach, asparagus, and amongst the fruit, figure plums of all kinds, loganberries, strawberries, raspberries, currants and gooseberries.

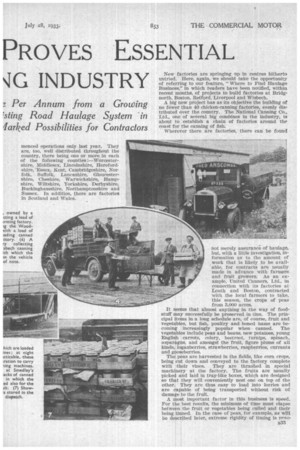

The peas are harvested in the fields, like corn crops, being cut down and conveyed to the factory complete with their vines. They are thrashed in special machinery at the factory. The fruits are usually picked and laid in tray-like boxes, which are designed so that they will conveniently nest one on top of the other. They are thus easy to load into lorries and are capable of being transported without risk of damage to the fruit.

A most important factor in this business is speed. For the best results, the minimum of time must elapse between the fruit or vegetables being culled and their being tinned. In the case of peas, for example, as win be described later, extreme rigidity of timing is prac Used and great care taken to ensure that a certain Emit of time is nOt exceeded, as hatween harvesting and Conviction of the canning operations This is not easy to arrange.

. One of the factories visited, that of Wisbech Produce Canners, Ltd., at Lynn Road, Wisbech, was designed, in the first place, for preserving peas. The season for this vegetable is from Mx weeks to two . months and ends about the middle of August. It IS, 'therefore, now.

at its height. .

The peas, as has been stated, are cut in the fields and brought on the vines to the factory, where they are thrashed in five machines, each " of which is capable of thrashing vines to produce one or two tons Of peas per hour. During the season these. machines work 24 hours per day and the capacity is, therefore, about 1.25 tons of shelled peas per day. As, however, nearly 10 tons of vines are needed to produce a ton of Shelled peas, the factory must accept upwards of 1,000 tons of pea vines per.day.

All Types of Vehicle Employed.

These are brought in by road in all sorts and sizes of vehicle. Moreover, as transport can be satisfactorily carried on only during the daylight hours, some of the loads are transferred to conveyors, which are in operation at night.

The peas, as in the case of other vegetables and fruit, are all collected from a radius of three or four miles of the factory, and, as a general rule, peas are canned or bottled within three hours of shelling. So important is this time factor that where, as happens sometimes in the ease of a farmer producing a big crop, he prefers to thrash his own peas, a representative of the . factory is invariably present to time the operation and to make sure that the maximum of four hours from harvesting to canning or bottling is not exceeded.

A variety of vegetables and fruits is canned at the same factory. Most vegetables are brought by road in sacks—beans, for example, being carried in 40-lb. bags at the rate of 300-400 bags per day during the season. Approximately 1,000 tons of vegetables, other than peas, are handled per annum. Of fruits, plums and strawberries are the principal products. These are accepted at the factories in trays, as above described, at

the rate of 70-80 tons of plums per day and 20-30 tons of strawberries.

Sugar is obtained from the sugar-beet factory at. King's Lynn, that commodity also being hauled by road, in average quantities of 20-30 tons per day. In the case of this factory, the cans in their cartons come by rail, the input being about 250,000 cans per da,y. Fruit and vegetables canned at the factory of Baird, Wolton and May, Ltd., Barming, near Maidstone, are collected from farms within a 25-mile radius. Generally, vehicles of 30-cwt. to 2i-ton capacity are used. The same class of flat wood tray is employed for the conveyance of the fruit. Each ti-ay holds 20-28 lb. and, owing, to the facility with which they nest one in another, they can be stacked in piles 20 high 'vvithout risk of damage either to themselves or to the fruit. In the height of the season, it is the rule to return empty cases equal in number.to the full ones accepted. There are thus regular return loads. for the fruitconveying vehicles.. Other incoming loads to the factory are sugar, cans and sundries. Last season, the sugar import amounted to six tons per day. This year it will probably be more.

The cans arrive packed in cardboard cartons, which are used to hold the containers when full. Cans are collected from London and the tinned fruit and vegetables are returned to London for distribution thence.

Why Motors Are Preferred.

Nearly all transport is by road, and Mr. Aubrey Wolton told us that road haulage was preferred because of the importance of having supplies promptly and to time. in his experience, only road transport can give these facilities.

At the canning factory at Woodbridge, Suffolk, fruit Is collected over a somewhat wider area and part of the supply comes by rail, special arrangements being made with the railway companies which enable proper recognition of the time element to be made.

A good proportion of the fruit is, however, brought to the factory by road. The empty cans are brought from the Acton works to the British Canning Co., and the system of dispatch from this factory tends to offer steady loads throughout the year, as it is the custom to retain and store during the summer and label and dispatch during the winter.