EW IDEAS IN BAKERY VANS

Page 46

Page 47

If you've noticed an error in this article please click here to report it so we can fix it.

Our Bodybuilding Expert Suggests Attractive and Useful Designs for Vans for Wholesale and Retail Bakers and Confectioners VANS of 8-10-cwt, capacity are used for the house-to-house delivery of bread, whilst the larger patterns are required by the bakery which supplies retailers. In its simplest form, the baker's vehicle is a boxvan with doors at the back and a partition behind the driver's seat. Access to the load from the front is desirable, in order to save time, whilst on the near side of the partition there should be a sliding door to protect the bread against dust.

As a food product is carried, ventilation is necessary. Louvre ventilators are improved by guarding them at the back with metal gauze. Formerly, the ventilation of the bakery van was of particular importance, in order to eliminate the hot air arising from the freshly baked bread, but now it is cooled before it is wrapped.

Should the van be loaded from the end or the side? Although most goods vehicles have back doors, the larger ones have, for many years, been equipped with side doors and side-hinged flaps. In fact, the wholesale baker has shown more readiness to adopt this style of bodywork than many other tradesmen. Those who prefer back doors point out that, when open, they do not obstruct the footpath. The same remark applies when sliding trays are moved in and out.

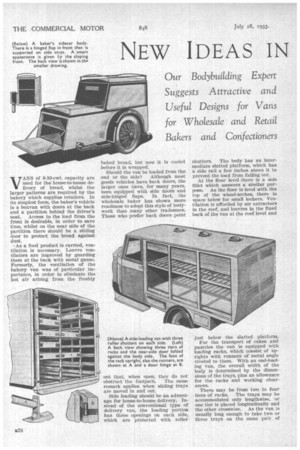

Side loading should be an advantage for house-to-house delivery. Instead of the conventional type of delivery van, the loading portion has three openings on each, side, which are protected with roller shutters. The body has an intermediate slatted platform, which has a side rail a few inches above it to prevent the load from falling out.

At the floor level there is a side fillet which answers a similar purpose. As the floor is level with the top of the wheel-arches, there is space below for small lockers. Ventilation is afforded by air extractors In the roof, and louvres in the fixed back of the van at the roof level and just below the slatted platform. For the transport of cakes and pastries the van is equipped with loading racks, which consist of uprights with runners of metal angle riveted to them. With an end-loading van, the overall width of the body is determined by the dimensions of the trays, plus an allowance for the racks and working clearances.

There may be from two to four tiers of racks. The trays may be accommodated only lengthwise, or one tier is placed longitudinally and the other crosswise. As the van is usually long enough to take two or three trays on the same pair. of runners, the inner trays are inaccessible without removing those behind them, for which reason the addition of side doors is an advantage. Side doors also give easy access when fitted on both sides of the van and the racks are arranged transversely.

Trays are loaded directly by hand, or on roller conveyers. In other instances use is made of trucks with runners, so that several trays may be wheeled to the van at a time. The runners for carrying trays of pastries are about 7 ins, apart and the trays are seldom more than 4 ins. deep. Trays of bread are carried by using only alternate runners.

The runners' and their supports are sometimes made detachable so that the van may be used for other purposes, or to facilitate cleaning. The vehicle also serves a double purpose if the box-type body be mounted on a platform When the box body is removed, the remaining platform becomes available for fetching a load of flour or other raw material.

The back doors of a pastry van are hung on hinges which have a pin centre in line with the side of the body. The doors may then be opened right back against the sides of the van, avoiding obstruction to the movement of the trays.

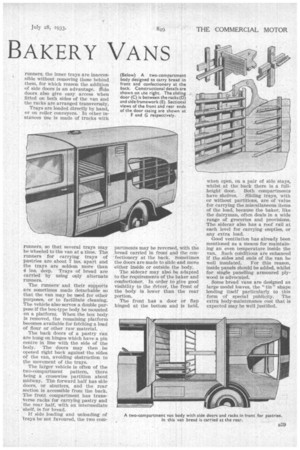

The larger vehicle is often of the

• two-compartment pattern, there being a crosswise partition about midway. The forward half has side doors, or shutters, and the rear section is accessible from the back. Thea front compartment has transVerse racks for carrying pastry and• the rear half, with an intermediate shelf, is for bread.

' If side loading and unloading of trays be not favoured, the two com partments may be reversed, with the bread carried in front and the confectionery at the back. Sometimes the doors are made to slide and move either inside or outside the body.

The sidecar may alse be adapted to the requirements of the baker and confectioner. In order to give good visibility to the driver, the front of the body is lower than the rear portion.

The front has a door or flap hinged at the bottom and is held,

when open, on a pair of side stays, whilst at the back there is a fullheight door. Both compartments have shelves. Sliding trays, with or without partitions, are of value for carrying the miscellaneous items of the load, because the baker, like the dairyman, often deals in a wide range of groceries and provisions. The sidecar also has a roof rail at each level for carrying empties, or any extra load.

Good ventilation has already been mentioned as a means for maintaining an even temperature inside the van. Such conditions are enhanced if the sides and ends of the van be

well insulated. For this reason, inside panels should be added, whilst for single panelling armoured plywood is advocated.

Some bread vans are designed as large model loaves, the "tin" shape lending itself particularly to this form of special publicity. The extra body-maintenance cost that is expected may be well justified.