DEMOUNTABLE DISTRIBUTION 11

Page 40

Page 41

If you've noticed an error in this article please click here to report it so we can fix it.

Body swop test

Dobson's equipment is unusual in that the body is lifted in one operation, before the support legs are lowered. Four vertically mounted hydraulic rams are positioned to lift the body at points well outboard of the centre line so that there is no risk of instability while the weight of the body is poised on the four jacks.

Demounting procedure involves initially releasing four simple twistlocks. The operating handle is lifted manually against a spring and turned through 90deg. Slots 'locate the lever positively in either the locked or released position. Because the locks are so simple to operate, they are vulnerable to tampering, although the diligent driver ought to spot a red-pointed handle out of position before driving off. Sufficient power to lift a laden body of 10 tons or more in one movement is ensured by using a pto-driven hydraulic pump. On Storage and Haulage's Leyland Laird LR 1200 chassis a pto engagement lever is floor-mounted inside the cab — preventing unauthorized operation.

A single lever controls the main lifting and lowering operations, with two supplementary levers for levelling the front or rear pair of rams in the event of a load biased to one side. A hand throttle lever, regulating the hydraulic pump's driven speed, has been added by S & H alongside the main control box.

Total travel in each ram is generous at about 14in., which makes allowance for some variation in chassis types, although S & H has found that different depths of underfloor structure on bodies for different duties can upset interchangeability. This is because Dobson's legs, unlike many competitors', are non-telescopic. In itself this is a strong feature — doing away with the dirt and corrosion problems in a sliding joint. But variations in body-sill — and therefore leg pivot — height betvi different bodies in a fleet call for longer and increased ram travel.

Spring-loaded locks locate the legs sa and positively in both the folded lowered positions. Conveniently shaped] withdrawal handles are provided so there is little likelihood of barked knucl However, care is needed when stowing legs. Each one is pulled out on its hingeand when pushing it back the fingers ci be trapped between leg and base frame. leg locks are "self-locating", but on the H vehicle accumulated road dirt prevei one leg being pulled out sufficiently for lock to engage. The inboard end of hinge-pin could with advantage be enclosed against the elements.

In the crucial matter of body /ehl alignment during the remounting opera the Dobson system must be awarded marks. As long as the driver avoids foi the legs with his rear wheels (and he h total of 12in. lateral clearance) then body will come into line. Each ram head a chamfered surround. As the ram is ri

,oes'into an inverted "dish" in the body or structure. The 16in.-diameter "dish" a 4in.-wide conical surround so that le initial alignment can take place as the

d of the ram contacts the dish surround. :re is, however, minimal scraping of the ; on the ground.

fter stowing the legs, the body — in its rtially aligned" state — is lowered on to the chassis, where two 6in.-diameter pins (one front, one rear) on the vehicle centreline engage in mating 6--in.-diameter holes in the body. Thus, the final alignment occurs with all legs clear of the ground. Some idea of the accuracy of alignment can be gained from the twistlock crossheads being only lin, narrower than the slots in which they engage.

From the point of view of simplicity the Dobson design scores over many ,other hydraulic systems. Speed of operation is affected to some extent by the driver's having to walk round the vehicle twice — once to release or engage the twistlocks, and again to raise or lower the support legs. If some form of hydraulically operated body locks, spring loaded into the locked position, could replace the twistlocks, then the tampering risk would be eliminated and time saved involved in twistlock operation.

Nevertheless the system is no sluggard. The 20ft body on S & H's Laird was offloaded in lmin 20sec after clearing the road dirt from the leg hinge mechanism. Remounting took 2min 5sec.

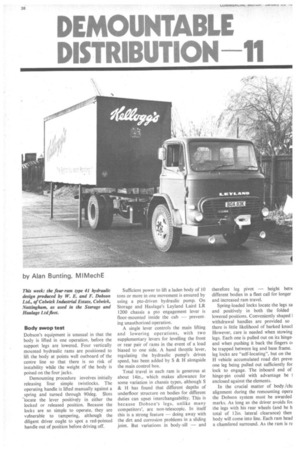

Service experience Storage and Haulage has operated a fleet of Dobson demountables for some years, under contract to Burmah-Castrol. The latest additions are for carrying breakfast cereals for the Kellogg Co of Great Britain Ltd.

Four Laird chassis are being put into service on the Kellogg contract, working with two special York drawbar trailers and 10 curtain-sided bodies built by F. S. Cartwright and Sons Ltd, of Altrincham, Cheshire. The demountable bodies are completely interchangeable between the drawing vehicles and trailers.

By switching to swop-bodies, S & H is able to avoid late-shift loading. At the same time the drawbar trailer refinement facilitates double-load daily deliveries to supermarkets and so on without having to return to the depot between times.

The only criticisms S & H voice against the system concern the exposure of the leg hinges to the weather, and the risk of forgetting to release the twistlocks before lifting. The company also acknowledges the relatively high cost of the Dobson equipment.