HIGH PER] )RMANCE

Page 50

Page 51

Page 52

Page 53

If you've noticed an error in this article please click here to report it so we can fix it.

in Latest Passenger Chassis

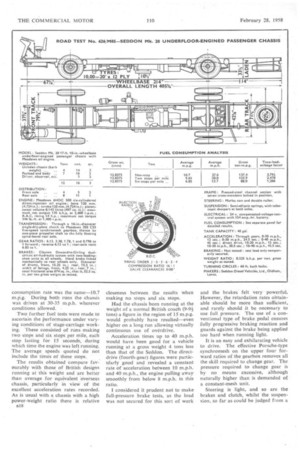

Seddon's First Design with Horizontal Underfloor Engine has Meadows 135 b.h.p. Unit and Five-speed Synchromesh Gearbox : High Power Gives Good Hill Climbing and Acceleration By John F. Moon, A.M.I.R.T.E.

RAPID acceleration rates, fast hill-climbing performance and high road speeds are becoming the essential requirements of public service vehicles in many parts of the world. Even in Great Britain there is a trend in this direction, which is necessary to keep up running schedules despite traffic delays. Motorways, when they arrive, will further empha

size the need for high speed. .

The new Seddon Mark20 .underfloor-engine passenger chassis, which was announced in the February 14 issue of The Commercial Motor, is an excellent example of this trend. Although a relatively small power unit is employed—the Meadows 8.143litre oil engine—its high output gives the three properties already mentioned. Moreover, the average fuel

consumption rate is reasonable for a vehicle of this type, particularly as the one tested had cowered only eight miles before test figures were taken.

Such was the performance of the Meadows engine, running at a gross vehicle weight of over 12.1 tons, that

I consider that it would be suitable for use in normal double-decker

chassis, for this country and overseas, in addition to heavy-duty singledeckers and high speed coaches. Furthermore, its high power-to-weight ratio makes it applicable to heavy goods chassis, giving excellent performance without the usual bulkand weight penalties.

The new Seddon is the first to have been produced With a horizontal underfloor engine. In the past, Seddon passenger chassis have had underfloor, rear and forward engines, all vertical, and these models are still in production, so that the range of chassis types is wider than is offered by any other manufacturer in this country.

'Basically conventional in layout, the Mark 20 chassis is notable for its low frame height-2 ft. 94. in. •laden—and the use of a dual-circuit air-hydraulic braking system, this being a valuable safety feature. The chassis tested was a left-hand-drive version with a 17-ft. 10-in.-wheelbase, making it suitable for a 34-ft.-long bus body. Shorter models for the home market are to go into production later.

The Meadows engine, which has " square" bore and stroke dimensions to give a low maximum piston speed, has gross and net power outputs of 150 b.h.p. and 135 b.h.p. respectively, the governed engine speed being 2,400 r.p.m. A mechanical governor is fitted to the C.A.V. fuel-injection pump, and automatic advance-and-retard linkage is incorporated in the engine timing gears.

Twin paper-element fuel filters are fitted and a large oil-bath air cleaner, with twin centrifugal-type pre-cleaners, is mounted on the right-hand frame member, adjacent to the engine.

The water-cooled air compressor is belt-driven from the front of the crankshaft, and a jackshaft taken forward from the same point drives the frame-mounted dynamo, a further shaft forward of the dynamo driving the radiator fan through an easily adjustable V-belt. The cooling system is not pressurized, but the fan is closely cowled and an additional header tank is supplied for mounting on the frame.

Mounted as a unit with the engine is a Meadows 350 CS5 five-speed synchromesh gearbox, driven through a I6-in.-diameter clutch, which has hydraulic actuation. The gearbox can be supplied with a direct top gear and close intermediate ratios (low being 7.68 to 1), or an overdrive top gear—as tested. The engine-gearbox unit is mounted at three points, with a single rubber bush carrying the front of the unit and twin rubber bushes, housed in a tubular extension to the clutchcasing, at the rear.

A very short propeller shaft takes the drive to the Moss 10-ton spiralbevel rear axle. This axle has a ratio of 6.83 to 1, which, with the overdrivetop gearbox, gives the chassis a maximum road speed of over 55 m.p.h., or 42 m.p.h. if the direct-drive-top unit is fitted.

Semi-elliptic springs, 3-t-in, wide, are .employed at both axles. The front springs, which have 10 leaves, have 44-in, eye centres, whilst the 17-leaf rear springs have 60-in, eye centres. Telescopic dampers are fitted all round.

Air-hydraulic Brakes Clayton Dewandre-Girl ing airhydraulic brakes are used, there being separate air and hydraulic circuits to each axle. The brake pedal actuates the dual air valve through a rod linkage. Adequate frictional area is assured by the use of 151-in. by 41-in. front brakes and 151-in. by 7-in, rear brakes, giving a total facing area of 674 sq. in. The two air-hydraulic actu. ators are located in line on the inside of the right-hand frame longitudinal, close to the road spring..

The chassis frame is a bolted assembly with seven cross-members. The side members are of 17in, material with 21-in, flanges and a maximum depth of 81 in. These members are Rat-topped except for a slight kick-up over the rear axle, and the lower flanges are tapered .upward slightly at

their extreme ends. A spare-wheel carrier is fitted at the rear of the frame, and the wheel itself is mounted on a sliding cradle to make for easy removal.

A square-section 40-gaI. fuel tank is located behind the batteries, which in turn are behind the rear axle. This arrangement, combined with the rearward engine position, is to guard against overloading the front axle when crush-load bodies are fitted.

Maximum gross weight allowance is 12 tons 12 cwt. The recommended front and rear axle loadings are 4.6 tons and 8 tons respectively: 10.00-20in. (12-ply) tyres are fitted as standard.

As supplied for test the Mk. 20 chassis was fitted with a makeshift platform to.carry a load of -iron Jalocks and road springs. This body was mounted so as to give somewhere near the estimated weight distribution, and the total imposed load was 7 tons 181 cwt. This brought the gross running weight to slightly more than the recommended maximum.

For the first series of tests the chassis was driven to Buckstones Road, Shaw, a 11-mile climb with an average gradient of I in 12 and a maximum gradient of 1 in 61. The climb was made in an ambient temperature of. 47° F. and at the start the temperature of the coolant in the header tank was. 137° F: The top of the hill was reached in. the surprisingly short time of 71 minutes, the lowest gear employed_ being second, which was engaged for 51 minutes. A temperature rise of

31° F. was recorded, which is reasonable for a brand-new engine and shows an adequate cooling margin for normal overseas use.

After a fade test made down the hill at 20 m.p.h. in neutral, which showed excellent anti-fade properties, the chassis was returned to the 1-in-61 section, where it was stopped. Although the rear brake drums were still hot from the fade test the hand brake held the chassis on this slope.

A second-gear restart was, then attempted and, to my surprise, was successful, the engine pulling away smoothly without the clutch having to be slipped excessively: This was repeated several times and on each occasion slight hazing was noticed at the exhaust outlet.

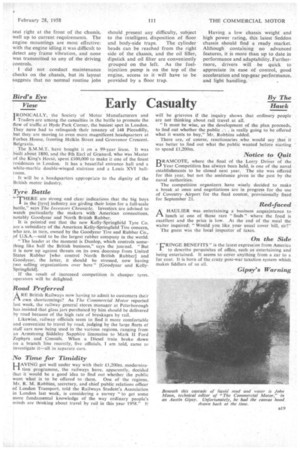

Fuel-consumption tests, for which a calibrated tank was employed, were conducted on a slightly undulatingout-and-return circuit along: The Broadway, Chadderton. On the first non-stop run excessive traffic was encountered and the course was cornpleted at an average speed of. only 21.8 m.p.h., the consumption rate being 10.7 m.p.g.

The run was then repeated under _clearer traffic conditions and the average speed was 27.6 m.p.h. The fuelB17 consumption rate was the same-10.7 m.p.g. During both runs the chassis was driven • at 30-35 m.p.h. wherever conditions allowed.

TwO further fuel tests were made to ascertain the Performance under varying conditions of stage-carriage working. These consisted of runs making two stops and six stops per rnile,.eaeh stop lasting for 15 seconds, during which time the engine was left running. The average speeds quoted do not include the times of these stops.

The results obtained compare favourably with those of British designs running at this weight and are better than average for equivalent Overseas chassis, particularly in view of the excellent acceleration rates recorded. As is usual with a chassis with a high power-weight ratio there is relative B18

closeness between the results when making no stops and six stops.

Had the chassis been running at the weight of a normal British coach (9-91 tons) a figure in the region of 15 m.p.g. would probably have resulted—even higher on a long run allowing virtually continuous use of overdrive.

. Acceleration times up to 40 m.p.h. would have been good for a vehicle running at a gross weight 4 tons less than that of the Seddon. The directdriVe (fourth-gear) figures were particularly good and revealed a constant rate of acceleration between 10 m.p.h. and 40 m.p.h., the engine pulling away smoothly from below 8 m.p.h. in this ratio.

I considered it prudent not to make full-pressure brake tests, as the load was not secured for this sort of work

and the brakes' felt very powerful. However, the retardation rates obtainable should be more than sufficient, and rarely should it be necessary to use full pressure. The use of a conventional type of brake pedal ensures fully progressive braking reaction and guards against the brake being applied too hard when running light.

It is an easy and exhilarating vehicle to driveThe effective Porsche-type synchromesh on the upper four forward ratios of the gearbox removes all the skill required to change gear. The pressure required to change gear. is by no means excessive, although naturally higher than is demanded of a constant-mesh unit.

Steering is light, and so are the brakes and clutch, whilst the suspension, so far as could be judged from a seat right at the front of the chassis, well up to current requirements. The engine mountings are most effective: with the engine idling it was difficult to detect any frame vibration, and none was transmitted to any of the driving controls.

I did not conduct maintenance checks on the chassis, but its layout suggests that no normal routine jobs should present any difficulty, subject to the intelligent disposition of floor

and body-side traps. The cylinder • heads can be reached from the right side of the chassis, and the oil filler, dipstick and oil filter are conveniently grouped on the left. As the fuelinjection pump is on the top of the engine, access to it • will have to be provided by a floor trap.

Having a low chassis weight and high power rating, this latest Seddon chassis should find a ready market. Although containing no advanced features, it is more than up to date in performance and adaptability. Furthermore, drivers will be quick to appreciate its ease of control, good acceleration and top-gear performance, and light handling.