ENSURING ACCURACY IN MANUFACTURE.

Page 22

If you've noticed an error in this article please click here to report it so we can fix it.

Some of the Reasons Why the Saurer Chassis is Winning a World-wide Reputation.

TILE famous Swiss company, Adolphe Saurer, have been renowned for many years for the high quality of their productions, which have culminated in the Seaver chas,sis. The engineering experience of the company dates back some 70 years, from the time when Franz Sauter started his own factory in Switzerland with a staff of two workmen. At that time, of course, petrol motor vehicles were not thought of, and the works specialized in making parts of embroidering machines.

The founder of the firm died in 1882, and Adolphe and his brother became the chiefs with a staff increased to 500.

The company having reached the period of automobile construction, the first commercial vehicle, witha singlecylindered horizontal engine with opposed pistons was delivered to Kock, of Paris, in 199L In 1903 the first 5 ton machine with a fouracylindered engine was produced, but it proved too expensive, and a lighter 21 ton type was made, this being followed later by others of 2, 3, 31 and 4 ton capacity, whilst a 30 cwt. model was changed over in course of manufacture from chain drive to carclan drive. A number of buses with specially low chassis were delivered in 1904 for service on the London streets, and at the Paris Exhibition in the same year the Saurer was much faVonred because of its unique features, including an air-pressure power starter, the now famous engine brake, and a special carburetter.

Saucer vehicles possess many unique features, including a dinec't bevel drive which eliminates the need for a double reduction gear, dished wheels which give greater tyre mileage, a bail bearing crankshaft, and carefully balanced camshaft.

One of the. most important points is the patent engine brake, to which we have already alluded. This is operated by the throttle lever, which-moves the camshaft longitudinally, bringing special cams into operation, and thus making the pistons coshiell against) air.

Anotheraspecial feature is the auto matic retarding of the -spark when the starting handle is engaged.

Now we must refer to actual points in the manufacture. Throughout the chassis the most careful attention is paid to the provision of materials of the highest

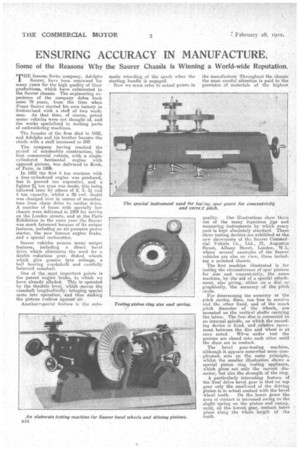

quality. Our illustrations show .thiee

out of the many ingenious jigs and measuring inatruments by which every part is kept absolutely standard. These three testing devices are exhibited at the. new showrooms of tha Saurer Commercial. Vehicle Cu., Lid., 21, Augustus Street, Albany Street, London, W.1, where several examples of the &surer vehicles, are also on view, these including a polished chassis.

The first machine illustrated 'is fer testing the circumference of spur pinioas for size and concentricity, the same machine by the aid of a special attachment, also giving, either on a dial or graphically, -the accuracy of the pitch circle.

For determining the accuracy ot the .pitch eireles, discs, one free to revolve and the ether fixed, and of the exact pitch diameter of the wheels, are mounted on the vertical shafts carrying the latter. The free disc is connected to an internal spindle, on which the recording device is fixed, and relative movement. between the disc and wheel is at

once noted. under test the pillions are closed into each other until the discs are in contact.

Theiaevel gear-testing machine, although it appears somewhat more complicated, acts on the same principle, whilst the smaller illustration shows a special piston ring testing appliance, which gives not only the correct diameter, but also the strength of the ring.

A particularly, interesting feature of the final drive bevel gear is that on top gear only the small-end of the driving pinion is in actual contact with .the bevel wheel teeth. On tha lower gears the area of contact is increased owing to the. alight 'spring on the pinion and casing, until., on the lowest gear, contact takes place along the whole length of the teeth.