For DRIVERS, MECHANICS & FOREMEN.

Page 21

If you've noticed an error in this article please click here to report it so we can fix it.

A PRIZE OF TEN SHILLINGS is awarded each week to the sender of the best letter which we publish an this page ; all others are paid for at the rate of a penny a /foto, with an allowance for photographs. Ali notes are edited before being published. Mention your employer's name, in confidence, as evidence of good faith, Address. D., M. and F., " The Commercial Motor," 7-35, Rosebery Avenue, London, E.G. 1.

Lamps Alight—

Light your lamps at 6.11 in London, 6.48 in Edinburgh, 6.13 in Newcastle, 6.20 in Liiverpool, 6.17 in Birmingham, 6.21 hi Bristol, and 7.5 in Dublin.

Making Knight Sleeve Valves.

The sender of the following communication has been awarded the tOs: prize this week.

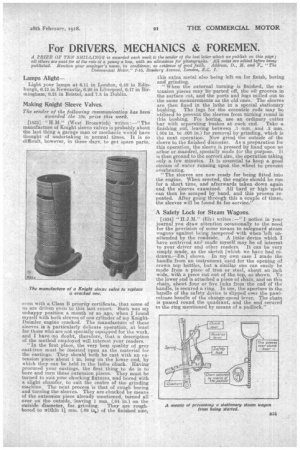

[1833] " H.M:" (West Bromwich) writes :—"The manufacture of Knight sleeve valves is probably about the last thing a garage man or mechanic would have thought of undertaking in normal times. It is so difficult, however, in these days, to get spare parts, even with a Class B priority certificate, that some of us are driven even to this last resort. Such was my unhappy position a month or so ago, when I found myself with both sleeves of one cYlincler of my KnightDaimler engine cracked. The manufacture of these sleeves is a particularly delicate operation, at least for those who are not specially equipped for the work,

• and I have:no doubt, therefore, that a description of the method employed will interest your readers. "In the first place, the very best quality of grey east-iron must be insisted upon as the .material for the castings. They should both be cast with an extension piece about 1 in. long on the lower end, by which they can be held in the lathe chuck. Having procured your castings, the first -thing to do is to bore and turn theseextension pieces. They must be turned to suit your chucking fixtures, and bored with a slight chamfer, to suit the centre of the grinding machine. The next process is that of rough boring and turning the sleeves. They are chucked by means of the extension piece already mentioned, turned all over on the outside, leaving 1 mm. (.04 in.) on the outside diameter, for grinding. They are rough bored to within l mm. (.06 ins) of the finished size,

this extra metal also being left on for finish, boring and grinding. "When the external turning is finished, the extension pieces may be -parted off, the oil grooves in the surface cut, and the ports and. lugs milled out to the same measurements as the old ones. The sleeves are then fixed in the lathe in a special stationary

bushing. The lugs for the eccentric rods may be utilized to prevent the sleeves from turning round in this bushing. For boring, use an ordinary cutter bar with separating bushes at each end. Take -a finishing cut, leaving between .1 nun. and .2 mm. (.004 in, to .008 in.) for removal by grinding, which is the next operation. Now grind the outside of the sleeve to the finished diameter. AS a preparation for this operation, the sleeve is pressed by hand upon an arbor or rilaaidrel, specially made for the purpose. It is then ground to the correct size, the operation taking only a feW minutes.. It is essential to keep a good stream of water running upon the wheel to prevent everheating.

"The sleeves are now ready for being fitted into the engine. When erected, the engine should be run for a short time, and afterwards taken down again and the sleeves examined. All hard or high spots can then be scraped by hand; and this process repeated. After going thrOugh this a couple of times, the sleeves will be found fit far service."

A Safety Lock for Steam Wagons.

[1834] "H.J.A.i." (Ely) writes :—" I notice in your journal you draw attention occasionally to the need for the provision of some means to safeguard steam wagons against being tampered with when left urn attended by the roadside. A little device which I have contrived and made myself may be of interest to your driver and other readers. It can be very simply made, as the sketch [which we have had redrawn.--En] shows. In my own ease I made the handle from an instrument used for the opening of crown top bottles, but a similar one can easily be made from apiece of iron or steel, about an inch wide, with a piece cut out of the top, as shown. To the lower end is attached a piece of ehain, and on this chain, about four or five links from .the end of the handle, is secured a ring. In use, the aperture in the. handle of the safety device is slipped over the pawlrelease handle of the change-speed lever. The chain is -passed round the quadrant, and the end secured. to the ring mentioned by means of-a padlock." .