Special Steels for Motor Vehicles.

Page 8

If you've noticed an error in this article please click here to report it so we can fix it.

There is one most important subject, in. connection with the motor-vehicle industry, which, we think, has not received the attention it deserves, and it is, therefore, with every satisfaction that one sees, on all sides, signs of a greater and growing i interest in the question of shock-resisting steels for use n the construction of motor vehicles. It has been asked how, and why, is it that the Sheffield steel manufacturers are better able, at the present date, to cater for the needs of this industry than was the case a few years ago? We think that this could not, very well, have been otherwise. It must be understood that the development of the motor vehicle has revolutionised, at least in one branch, the steel trade_ It is only, comparatively, very recently, that the value of the special qualities of such alloys as nickel, chrome, and vanadium in combination with iron have been fully realised; and there is no doubt, that the rapid strides which have been made in the knowledge of these special steels is, directly, due to the urgent need of materials possessing exceptional strength, and toughness, for use in the construction of motor vehicles. Present-day knowledge of these materials is the result of almost countless tests and experiments, made at great expense, in the steel works, within the last four OT five years. In fact, owing to the high price of the alloys mentioned, and the somewhat elaborate and expensive nature of the necessary testing machines, the cost of making series after series of experiments has been so great, that the actual manufacture of the new steels has had to be left, almost entirely, in the hands of several of the leading steel melters.

If the motor engineer has had, in the oast, a legitimate complaint to make of his inability to get the steels he wanted, we do not think this is the case nowadays. One hears in Sheffield, on the other hand, that, only three or four years ago, and, perhaps, even more recently on the whole, the motor engineer--there were, of course, notable exceptions—did not take any great interest in the efforts of the steel maker to supply him with a better type of material; he—we repeat there were exceptions—viewed these efforts, in fact, with, shall we say, indifference, professing a perfect confidence in the old type of mild steel. This lack of encouragement to the steel maker, we believe, had, for a time, and to some extent, the effect of retarding, in this country, the investigations which were, on the Continent, being carried on with the greatest enthusiasm. There was, however, no doubt, from the first, that steels of the highest tensile strengths and toughness, would, ultimately, be in demand, as the earliest experiments, which were, chiefly, in nickel steels, proved that the old types of steel, however satisfactory these might be for parts of machinery where a little more weight was of no consequence, could be greatly improved upon, and must, necessarily, be adopted for purposes when the maximum strength, combined with the minimum weight, was essential.

The following two tests will show, at a glance, the great superiority of a 3 per cent, nickel steel over an ordinary, mild, Siemens-Martin (acid), steel bar, the greatest difference being in the elastic limit, a most important feature.

These tests are very ordinary, and must not be taken as showing any exceptional results ; they are, merely, stated for comparative purposes.

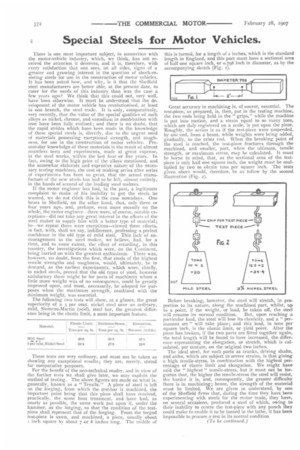

For the benefit of the non-technical reader, and in view of the further tests we shall give later, we may explain the method of testing. The above figures are made on what is, generally, known as a " Tensile." A piece of steel is left on the forging, from which the test-bar is machined, the important point being that this piece shall have received, practically, the same heat treatment, and have had, as nearly as possible, the same work put upon it, under the hammer, as the forging, so that the condition of the testpiece shall represent that of the forging. From the forged test-piece is sawn, and machined, a piece, usually about i inch square by about 7 or 8 inches king. The middle of this is turned, for a length a 2 inches, which is the standard length in England, and this part must have a sectional area of half one square inch, or 0.798 inch in diameter, as by the accompanying sketch (Fig. t).

Great accuracy in machining is, of course, essential, The test-piece, as prepared, is, then, put in the testing machine, the two ends being held in the " grips," while the machine is put into motion, and a strain equal to so many tons, which are duly registered on a scale, is put upon the piece_ Roughly, the action is as if the test-piece were suspended, by one end, from a beam, while weights were being added, gradually, to the other end. When the breaking point of the steel is reached, the test-piece fractures through the machined, and smaller, part, when the ultimate, tensile strength, or maximum stress, may be calculated. It must he borne in mind, that, as the sectional area of the testpiece is only half one square inch, the weight must be multiplied by two to obtain tons per square inch. The tests given above would, therefore, be as follow by the second illustration (Fig. 2).

Before breaking, however, the steel will stretch, in proportion to its nature, along the machined part, whilst, up to a point, if the weight, or load, be taken off, the steel will resume its normal condition. But, upon reaching a particular load, the steel will lose its elasticity, and a " permanent set" will take place; and this load, in tons per square inch, is the elastic limit, or yield point. After the piece has broken, if the two parts are fitted together again, the total length will be found to have increased, the difference representing the elongation, or stretch, which is calculated, per eentum, on the original two inches. The ideal steel, for such parts as cranks, driving shafts, and axles, which are subject to severe strains, is that giving a high tensile-stress, in combination with the highest percentage of elastic limit and elongation. We might have said the " highest " tensile-stress, but it must not be forgotten that, the higher the tensile-stress the steel will resist, the harder it is, and, consequently, the greater difficulty there is in machining; hence, the strength of the material must be limited. We are given to understand, by one of the Sheffield firms that, during the time they have been experimenting with steels for the motor trade, they have, on several occasions, produced a steel of which, owing to their inability to centre the test-piece with any punch they could make to enable it to be turned in the lathe, it has been impossible to procure a test in its normal condition