Silencers for Internal Combustion Engines.

Page 13

If you've noticed an error in this article please click here to report it so we can fix it.

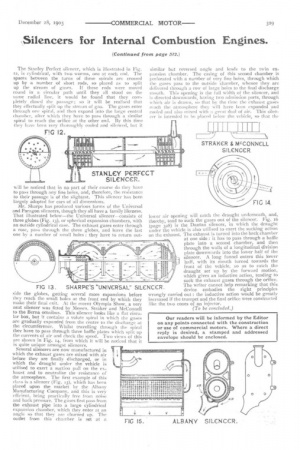

The Stinky Perfect silencer, which is illustrated in Fig. 12, is cylindrical, with two worms, one at each end. The spaces between the turns of these spirals arc crossed up by a number of short rods, so placed as to split up the stream of gases. If these rods were moved round in a circular path until they all stood on the same radial line, it would be found that they completely closed the passage; so it will be realised that they effectually split up the stream of gas. The gases enter through one spiral, and then expand into the large central chamber, after which they have to pass through a similar spiral to reach the orifice at the other end. By this time they have been very thoroughly cooled and silenced, but it will be noticed that in no part of their course do they have to pass through any fine holes, and, therefore, the resistance to their passage is of the slightest. This silencer has been largely adopted for cars of all dimensions.

Mr. Sharpe has produced various forms of the Universal and Paragon silencers, though they all have a family likeness. That illustrated below—the Universal silencer—consists ot three globes (Fig. 13), or spherical expansion chambers, with an outside cylindrical case. The exhaust gases enter through a rose, pass through the three globes, and leave the last one by a number of small holes : they have to return out side the globes, getting several more expansions before they reach the small holes at the front end by which they make their final exit. At the recent Olympia Show, a very neat silencer was fitted by Messrs. Straker and McConnell to the Berna omnibus. This silencer looks like a lint circu lar box, but it contains a volute spiral in which the gases are gradually expanded front the centre to the discharge at the circumference. Whilst travelling through the spiral they have to pass through three baffle plates which split up the currents of air and check the speed. Two views of this are shown in Fig. Li., front which it will be noticed that it is quite unique amongst silencers.

Several silencers are now manufactured in which the exhaust gases are mixed with air before they are finally discharged, or in which the draught under the vehicle is utilised to exert a suction pull on the eNhaust and to neutralise the resistance of the atmosphere. The first example of this class is a silencer (Fig. 15), which has been placed upon the market by the Alhany Manufacturing Company, and this is very cflivient, being practically free front noise and back pressure. The gases first pass from the exhaust pipe into a large cylindrical expansion chamber, which they enter at an angle so that they are churned up. The outlet from this chamber is set at a

similar but reversed angle and leads to the twin expansion chamber. The casing of this second chamber is perforated with a number of very tine holes, through which the gases pass to the outside chamber, whence they are delivered through a row of large holes to the final discharge mouth. 'this opening is the full width of the silencer, and is directed downwards, having two admission ports, through which air is drawn, so that by the time the exhaust gases reach the atmosphere they will have been expanded and cooled and also mixed with :t great deal of air. This silencer is intended to be placed below the vehicle, so that the lower air opening will catch the draughi underneath, and, thereby, Lend to suck the gases out of the silencer. Fig. lb (page 328) is the Dantan silencer, in which the draught under the vehicle is also utilised to exert the sucking action on the exhaust. The exhaust is turned into the back chamber at one side it has to pass through a baffle plate into a second chamber, and then through the walls of a longitudinal division plate downwards into the lower half of the silencer. A long funnel enters this lower half, with its mouth turned towards the front of the vehicle, so as to catch the draught set up by the forward motion, which gives an inductive action, tending to suck the exhaust gases through the orifice. The writer cannot help remarking that this device embodies the right principles wrongly carried out : the inductive action would be greatly increased if the trumpet and the final orifice were constructed like the two cones of an injector.

NCCR