CROSSLEY ,NGINE

Page 55

Page 54

Page 56

If you've noticed an error in this article please click here to report it so we can fix it.

THE name Crossley has for 60 years been identified with oil and gas engines, during which time over 100,000 power units have been sold and distributed all over the world. It is obvious, therefore, that when the Crossley engineers set about the task of producing an engine for road-transport work they had a fund of most valuable experience to act as the foundation stone to their efforts.

Furthermore, the company's activities in the passenger-vehicle field have unquestionably given the designing staff much useful data regarding operators' requirements from the point of view of general service conditions and the maintenance of fleets of vehicles over long and strenuous periods of working.

There are several points of special interest in the conception of this new Crossley project. For example, the layout of the unit has been planned so that crankshaft-speed and torque figures are comparable with those of the normal Crossley petrol engine; the result Is, of course, that it is possible to interchange engines without making any structural alteration to chassis details. The gearbox and rear-axle ratios remain unchanged, whilst the brake hook-up remains exactly the same as in the petrol chassis, for a vacuum pump Is installed on the auxiliary line of the new power unit to create the necessary suction for a Dewandre servo motor.

After riding in a Crossley oil-enginecl 50-seater bus, which is in general service on the streets of MancheSc32 ter, we were able to confirm the makers' claim that the handling of the vehicle is quite normal and that specially trained drivers are unnecessary. Apart from a slight compression knocking when under maximum loads the engine is silent in operation and behaves with the smoothness of a high-grade petrol unit.

An official of Manchester Corporation's transport department states that extraordinary fuel-consumption figures have been obtained. The first vehicle to be put Into commission—the 50-seater bus already mentioned —has now completed over 3,500 miles on one of the most arduous routes in the city, where it has been found possible for the driver to keep time with other petrol vehicles on the route and without the passengers being able to detect the difference in the type of engine employed.

A rate of. consumption of practically 10 m.p.g. has been achieved, despite the fact that only service mileage has been counted. The vehicle has, in addition, been used for a variety of other purposes, such as the instruction of drivers, experimental work, etc. A figure of between 12 m.p.g. and 14 would, therefore, seem to be not too optimistic a claim.

We will now turn to a consideration of details of construction, The accompanying illustrations show that the general lines of the unit are clean and that all parts are robust and fully up to the duties tha1 they have to perform. Internally the crankcase, crank shaft, camshaft andconnecting rods are splendid exam pies of modern engineering, for scientific design heo enabled strength to be coupled with lightness. Eacl main bearing of the crankshaft is supported in a deei web running right across the ease, and, as the cylindei block is a single casting of comparatively deep section the whole unit is remarkably rigid.

An interesting point concerns the manner in whicl the crankpins are bored out for lightness ; the holes art eccentric to the pins, in order to maintain the necessari strength near the webs.

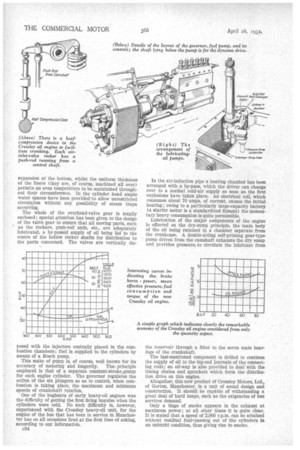

With a total piston-swept volume of 8,354 c.c., tht bore of the cylinders works out at 108 mm. and tilt piston stroke at 152.4 mm. At 1,800 r.p.m. over 85 b.h.p is developed, and the fuel consumption is at the rate o .485 lb. per b.h.p.-hour ; the Minimum consumptim figure of ,42 lb. per b.h.p.-hour occurs around 1,001 r.p.m,, which almost coincides with the point of maxi mum torque. The appended curves show graphical!, the whole characteristics of the unit.

The normal compression pressure is 430 lb. per sq. ir and the firing pressure is 800 lb. per sq. in., so that th peak temperatures are fairly high ; for this reaso special precautions have been taken to avoid clistorticy of the cylinders and cylinder heads.

The former components are "wet" liners with allow ance made for radial expansion at the top and axis c33 expansion at the bottom, whilst the uniform thickness of the liners (they are, of course, machined all over) permits an even temperature to be maintained throughout their circumference. In the cylinder head ample water spaces have been providecleto allow unrestricted circuletion without any possibility of steam traps occurring.

The whole of the overhead-valve gear is totally enclosed; special attention has been given to the design of the valve gear to ensure that all moving parts, such % as the rockers, push-rod ends, etc., are adequately lubricated, a by-passed supply of oil being led to the centre of the hollow rocker shafts for distribution to the parts concerned. The valves are vertically dis posed with the injectors centrally placed in the combustion chambers; fuel is supplied to the cylinders by means of a Bosch pump.

This make of pump is, of course, well known for its accuracy of metering and longevity. The principle employed is that of a separate constant-stroke omen for each engine cylinder. The governor regulates the action of the six plungers so as to control, when combustion is taking place, the maximum and minimum speeds of crankshaft rotation.

One of the bugbears of early heavy-oil engines was the difficulty of getting the first firing impulse when the cylinders were cold. No such difficulty is, however, experienced with the Crossley heavy-oil unit, for the engine of the bus that has been in service in Manchester has on all occasions fired at the first time of asking, according to our information.

C34 In the air-induction pipe a heating chamber has been arranged with a by-pass, which the driver can change over to a normal cold-air supply so soon as the first explosions have taken place. An electrical coil, which consumes about 70 amps. of current, causes the initial heating; owing to a particularly large-capacity battery (a starter motor is a standardized fitment) the momentary heavy consumption is quite permissible.

Lubrication of the major components of the engine is effected on the dry-sump principle, the main body of the oil being retained in a chamber separate from the crankcase. A double-acting self-priming gear-type pump driven from the camshaft exhausts the dry sump and provides pressure to circulate the lubricant from the reservoir through a filter to the seven main bearings of the crankshaft.

The last-mentioned component is drilled to continue the supply of oil to the big-end journals of the connecting rods; an oil-way is also provided to deal with the timing chains and sprockets which form the distribution drive on this engine.

Altogether, this new product of Crossley Motors, Ltd., of Gorton, Manchester, is a unit of sound design and construction. It should be capable of withstanding a great deal of hard usage, such as the exigencies of bus services demand.

Only a tinge of smoke appears in the exhaust at maximum power ; at all other times it is quite clear. It is stated that a speed of 2,000 r.p.m. can be attained without residnal fuelepassing out of the cylinders in an unburnt condition, thus giving rise to smoke.