TOUGH BUT JUICY

Page 48

Page 49

Page 50

Page 51

If you've noticed an error in this article please click here to report it so we can fix it.

With com•onents from Britain, America, France, Germany and Japan Foden's new S104 tractive unit is toug , powe u •ut wit poor ue consumption

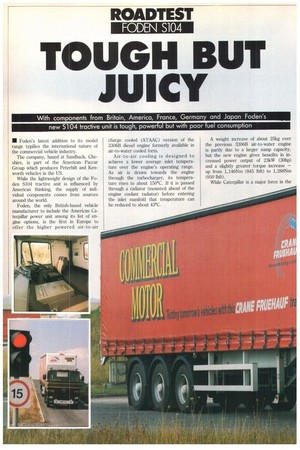

• Foden's latest addition to its model range typifies the international nature of the commercial vehicle industry.

The company, based at Sandbach, Cheshire, is part of the American Paccar Group which produces Peterbilt and Kenworth vehicles in the US.

While the lightweight design of the Foden S104 tractive unit is influenced by American thinking, the supply of individual components comes from sources around the world.

Foden, the only British-based vehicle manufacturer to include the American Caterpillar power unit among its list of engine options, is the first in Europe to offer the higher powered air-to-air charge cooled (ATAAC) version of the 3306B diesel engine formerly available in air-to-water cooled form.

Air-to-air cooling is designed to achieve a lower average inlet temperature over the engine's operating range. As air is drawn towards the engine through the turbocharger, its temperature rises to about 150°C. If it is passed through a radiator (mounted ahead of the engine coolant radiator) before entering the inlet manifold that temperature can be reduced to about 43°C. A weight increase of about 25kg over the previous 3306B air-to-water engine is partly due to a larger sump capacity, but the new engine gives benefits in increased power output of 23kW (30hp) and a slightly greater torque increase — up from 1,146Nm (845 lbft) to 1,288Nm (950 lbft).

While Caterpillar is a major force in the American heavy vehicle market, its success in Europe has been largely confined to plant equipment. This may explain why it is the latest engine manufacturer to introduce air-to-air cooling which is now widely accepted on the European scene as a means of improving all aspects of performance.

• TRANSMISSION

Eaton's Twin Splitter gearbox is now well established with more than 1,000 units in use since full production began at the French St Nazaire plant in April. Its concept is a development of the company's successful twin countershaft design with over two million units sold. The 12speed gearbox incorporates a four-position H-pattern gate with three split gears in each of the positions operated by a switching mechanism.

It is possible, and often practical — if not always desirable — to make both clean split changes and full gear lever movements without assistance from the clutch.

Spicer propeller shafts and needlebearing universal joints made at Wolverhampton continue the drive line. Rockwell's S160E single reduction hypoid axle is produced in Italy while the front forged axle is manufactured by GICN.

The air brake equipment is also produced by Rockwell but supplied from Germany as is the ZF steering box. Monolex wheels, supplied by George Fischer, have their origins in Switzerland and the Bridgestone tyres, a recent addition to the Foden option list, are Japanese. • While the chassis owes its origins to the US, the high tensile steel main longitudinal members are imported from Germany as Foden claims British Steel is unable to meet its specification.

Steel/aluminium air and fuel tanks are manufactured locally at Sandbach while the GRP/tubularframed cab, now accepted even by the military, is produced inhouse.

Installation of the Caterpillar engine appears to be similar to that of the air-towater cooled unit, except that air trunking is prominently mounted, running from the turbocharger on one side of the block forward to the front-mounted radiator and back to the inlet manifold on the nearside. Charge cooling is not dependent on the engine fan, which operates only as engine temperature dictates.

The cab tilts hydraulically through 750 to give excellent access to the engine compartment, but the lift pump is small and needs a great•deal of pumping to raise the cab fully. On lowering, the cab may need directing into the guides before it will lock clown but there is no need to align the fixed gearlever, thails to its cable linkage to the gearbox.

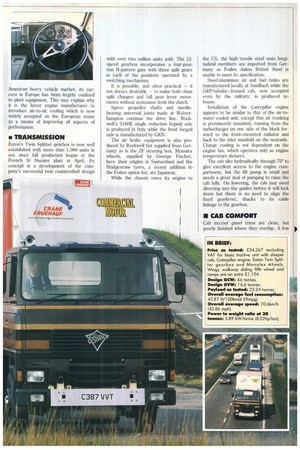

II CAB COMFORT

Cab interior panel trims are clean, but poorly finished where they overlap. A low first step and grab handles placed either side of the door make the climb to the driver's seat easy. A single bunk across the rear of the cab restricts rearward seat adjustment, but the high contoured back and firm squab offer ample support.

Tachograph and rev counter are prominently displayed among an array of gauges and warning lamps monitoring air pressure, fuel, oil pressure, engine temperature and battery charge rate.

A new, padded steering wheel gives a soft and warm feel for cold, early morning starts while the park brake lever, gear stick and foot controls are conveniently placed and of a practical size. An oddment tray located on top of the engine cowl doubles as a document box.

A switch for the diff-lock is mounted on top of the fascia alongside a warning lamp so that there is no reason to drive for miles with it engaged.

• PERFORMANCE

Another switch located nearer to the screen allowed us to drive at about the maximum legal limit with and without the Econocruise speed limiter in use. While operation is smooth, the device can only restrict the vehicle's speed when the engine is pulling. On overrun the vehicle is as free as ever to gather momentum on downhill gradients. The device had been set to come into operation at 100km/h (62mph), but the indicated speed was shown to be about 3% fast. In effect this restricted our maximum speed to less than the permitted 97km/h (60mph).

On both road and track the engine revved freely to give a lively performance, resulting in good hill climb times but also in relatively high fuel consumption.

Whenever practical in the higher gears, engine speed was kept to the most economical sector of the rev band — given as 1,400 to 1,600 — when working at its hardest. A road speed of 80km/h (50mph) in top gear relates to 1,400rpm, and at 97km/h (60mph) 1,650rpm. In practice the engine operates only a small percentage of the time at full load. At reduced work levels we have no way of knowing how the specific fuel consumption curve changes.

• FUEL ECONOMY

Overall a fuel consumption of 42.871it/100km (6.59mpg) must be described as poor for a unit which is being acclaimed as more efficient. Of the American engine suppliers, only Ctuiunins seem to have come to terms with European requirements for fuel economy.

Eaton's Twin Splitter gearbox reduces the workload of the driver. Split switching in each of the four gate positions can be pre-selected shortly before the change is required. Longer pre-selection intervals are not advisable as this increases the possibility of an inadvertent relaxation of the throttle pedal which could result in an unplanned change of gear.

Quick and clean as the gearchanging is, attempts to snatch an extra ratio on a hill climb, with or without the help of the clutch, often took longer than we were prepared to wait as the vehicle slowed.

Air suspension of the Isringhausen seats softened any road shocks transmitted up through the vehicle's suspension. Early in the test, while travelling over smooth A-road and motorway sections, it was some time before we realised that the seat had been set in a locked mode.

Over subsequent tough, narrow and bumpy hill sections the full damping movement proved a positive asset, considerably improving driver comfort.

• BRAKING

Under lull application the brakes pulled the vehicle up square and in-line but with a great deal of cab pitch. IFor well over half of the stopping distance from 65km/h (40mph) the drive axle alone locked, creating a potentially unstable condition and highlighting the inadequacy of the load sensing equipment.

As the brakes warmed on the long downhill descents, where the vehicle's speed needed constant checking, they soon began to smell strongly. Caterpillar has yet to develop an exhaust brake suitable for road-going vehicles.

• SUMMARY

As CM found in the past, the Caterpillar 3306B power unit did not excel in the fuel consumption stakes but it has a lively performance and a reputation for reliability.

Had an air-deflection kit been fitted, the results may have been slightly better. The omission of an exhaust brake inevitably puts greater demand on the service brakes.

Foden's composite cab construction can no longer be doubted. From the outside the styling is fussy but it is generally well fitted out and is quiet to drive.

Braking stability was not a problem on the road but this might be the time for Foden to add an anti-lock braking system to its extensive range of options.

0 by Bill Brock