For DRIVERS, MECHANICS & FOREMEN.

Page 21

If you've noticed an error in this article please click here to report it so we can fix it.

A PRIZE 01? TEN SHILLINGS is awarded each week to the sender of the hest letter Which we publish on 'this -page; all others are paid for at the rate of a penny a lane, with an allowaxce for photographs. All notes are edited before being published. Mention yonr employer's name, in confidence, as evidence of good faith, Address, V., M. and F., " The Commercial Motor," 7-2,5 Bosebery Avenue, London, B.C. 1.

Lamps Alight — Light your lamps at 6.15 in London, 6.55 in Edinburgh, 6.19 in Newcastle, 6.25 in Liverpool, 6.21 in Birmingham, 6.25 in Bristol, and 7,11 in Dublin.

Troubles Met when Converting a Touring Car.

[1781] " E.D." (Immingham) writes : —" I am now engaged 0.H.M.S.' in charge of a 500 h,p. motor boat, but before joining up was the proprietor of a

repair shop. It occurs to me that one or two of my experiences may be of interest to your readers. The first that comes to my mind is really a series of events in connection with a touring-car chassis which was converted for use as a light van. For a few weeks after conversion all went well.

"Troubles first occurred with the back axle. The sun-wheels, which were keyed on to the driving shafts, gave out by ,splifting from the corners of the keyway to the roots of the teeth.

After fitting a few renewals, I thought I would have a shot at redesigning the part, and came to the conclusion that to make the gearwheel solid with the shaft offered the only permanent remetly. It was, of course, an easy matter to acquire a piece of bar equal in diameter to the gear, and to turn it down so that itbecame the same diameter as the shaft for all of its length but the width of the gear. How to cut the teeth of the wheel, 'however, was a more difficult proposition. All the machinery I had in the shop was an old lathe and a small vertical drilL

"However, I looked out a pieceof cast-steel in. thick, and used it as a jig with which to mark off the roots of the teeth, A hole was then drilled at the root of each tooth space, and the share of the tooth roughly conformed to by the aid of a hack-saw. I then How made a special shaping tool, which I mounted in the slide-rest. The shaft was then placed between centres and the teeLh shaped by moving the rest, together with its tool, along by hand. Afterwards the cogs were polished, hardened, then polished again and the job was complete and good.

-My troubles were farfrom being ended, however.

Shortly after I had completed this repair, the satellite pinions began to fail in precisely the same way. These, as the sketch shows, were hollow and revolved on a spindle. Following on the method adopted in the case of the larger wheels, I made the spindles in one piece with the wheels (refer again to sketch), and the repair proved to be just as successful."

Safety First on a Steam-wagon Steering Gear.

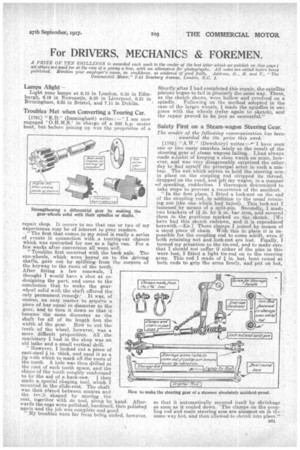

The sender of the following communication has been . awarded the 10s. prize this week: [1782] " A.W." (Dewsbury) writes I have seen one or two nasty smashes lately as the result of the steering gear of steam wagons failing. Lhad always. made athabit of keeping a close watch on mine, however, and was very disagreeably surprised the other • day, to find myself the principal actor in such a mishap. The nut which serves to hold the steering arm in place on the coupling rod stripped its thread, dropped on the road, and left my wagon, in a manner KA speaking, rudderless. I thereupon determined to • take steps to prevent a recurrence of the accident. "In the first place, I fitted a lock-nut on the end of the coupling -rod, in addition to the usual retaining nut (the one which had failed). This lock-nut I , fastened by means of a split-pin. SecondlY, I made , two brackets of in. by fr in. bar iron. and secured , them in the positions marked on the sketch. [We have had this sketch redrawn, and it is reproduced herewith.--ED.] These clamps I joined by means of a stout piece of chain. With this in place it is impossible for the coupling rod to come adrift, even if both retaining nut and lock-nut are lost. Finally, I turned my attention tn. the tie-rod, and to make sure.. that I should not suffer, if either of the pins in this were lost, Ifitted a light tie-rod on to the steering arms. This rod I made of in. bar, bent round at both ends to grip the arms firmly, and put on hot, so that it automatically secured itself by shrinkage as soon as it cooled down. The clamps on the coupling rod and main steering arm are alsooput on in the same way hot, and then alloWed to shrink into place."