Kom Drivers &Mechanics

Page 22

Page 23

If you've noticed an error in this article please click here to report it so we can fix it.

TEN SHILLINGS WEEKLY is paid for the best communication received, and one penny a line of ten words for anything else published, with an allowance for photographs.

Light Up Your Lamps At

4.56 or Thursday ; 4.55 on Friday ; 4.54 on Saturday ; 4.52 on Monday ; 4.52 on Tuesday ; 4.52 on Wednesday.

Chassis Alignment.

The sender of the following communication has been awarded the 108. prize this week.

[1389] "R.T." (Bedford :Hill) writes :—" It frequently happens that on reassembling after an overhaul, a chassis will run with a certain amount of harshness which is not traceable to any particular section of the engine or transmission. In the majority of such cases I have found, on further examination, that this fault is due to frame distortion and bad alignment of engine, gearbox or back axle. "Difficulty is often experienced in lining up a stripped frame, as its rigidity is largely derived from the engine and gearbox units when these are fitted up. It. will be realized that an accurate lining up of the component parts through the whole of the transmission is very necessary, otherwise undue wear at the joints and bearings is likely to be set up. "There are, no doubt, many of my fellow drivermechanics who have been placed in the same position as myself in this respect, and as I have given the matter a considerable amount of thought and attention, I enclose a sketch [We have had this redrawn.— En.] and send a description of the method I adopt in lining up ; its publication may be of use. "The chassis is supported on trestles at each end, and a point marked at the centre of the front and rear cross members. At these points two rods should be attached in a true vertical position, as shown in the top sketch, and between them, lengthwise of the chassis, are secured twise lengths gf string quite taut, one above and one below the frame. These, it will be E4

understood, give the centre line of the chassis. The engine is then placed approximately in position and by means of a plumb-line placed in contact with the two lengths of string before referred to, the correct position of the engine is soon found by plumbing the centre of the flywheel, and the front end of the crankshaft. It may be necessary, in order to get the engine quite true, to draw the bolt-holes before finally tightening down.

"The gearbox may now be treated in the same manner and the process continued through to the rear axle, packing up the brackets where necessary. it is surprising to find how many chassis can be improved and turned out quite in line by adopting this plan. If the bolt holes have been drawn to any considerable extent it is advisable, of course, to fit dowel pegs.

" If the bolts fit loosely there is considerable wear likely to be set up on universal joints, transmission gear, ball races, etc., and the accompanying harshness is a source of expense to owner and annoyance to driver."

A Various-sized Plug Gauge.

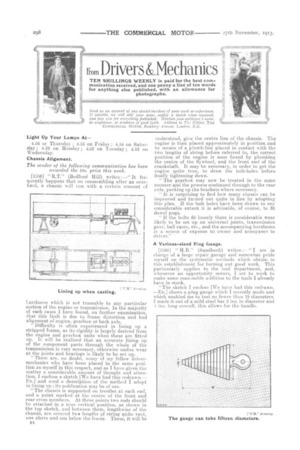

[1390] " H.B." (Sandbaeb) writes :--" I am in charge of a large repair garage and somewhat pride myself on the systematic methods which obtain in this establishment for turning out good work. This particularly applies to the tool department, and, whenever an opportunity occurs, I set to work to make some reasonable addition to the tools I already have in stock.

"The sketch I enclose [-We have had this redrawn. —En.] shows a plug gauge which I recently made and which enabled me to test no fewer than 15 diameters.

made it out of a mild steel bar 2 ins. in diameter and 4 ins, long overall, this allows for the handle. " The smallest bore which the gauge will take is .4 in, diameter and the largest 2 ins., these, as well as the intermediate sizes, being, of course, carefully turned and finished to the micrometer.

Ruch a tool, I consider, will prove useful to mechanics who are called upon to do any particular work of a small nature, and its use will tend to keep parts at least something like standard."

Chasing Up Damaged Threads on a Back Axle.

[1391] " R.G.D." (Huddersfield) writes :—" Last week I had a rear-axle repair to effect, and I think the method which I adopted to get over a little difficulty in the matter will interest your readers. The

trouble lay with the threads of the axle-tube, which were very badly damaged. The locking set-screw it appeared had not been sufficiently unscrewed when the nuts were detached at sonic time or other, and it was quite inadvisable to replace the retaining nuts under such conditions.

"I set about to effect chasing up the thread and send you a sketch of how this was managed [We have had this redrawn.—ED.]. I threaded a ring the same number of threads per inch as that of the axle, and cut this in halves. I milled faces to enable me to drill four holes to take in. diameter bolts on either side of the split ring. The device was then case. hardened.

"Unscrewing the four bolts, I placed the two halves of the ring on the forward end of the undamaged thread of the axle, screwed the four A in. bolts in place, and turned the nut, which gave me a lead towards the damaged end of the thread. By this means the threads on the ends of the axle were chased up in a very satisfactory way. The ina,king of new retaining nuts was, of course, not a very big job."

A Tip for Garage Lighting.

[1392] "W.B." (Richmond) writes :—" For a considerable while I experienced a deal of trouble in my garage owing to the breaking of the filaments of the electric hand-lamps. There are sonic half-a-dozen lamps in frequent use, and the flex is run from bayonet holders located on the pillars which support the roof of the garage.

Although the lamps have protections fitted to the bulbs, I found that, owing to their being placed carelessly on the benches and being subjected to further vibration by fitters hammering, the filaments broke, although the bulbs themselves were left undamaged.

" The following tip will exeilain how easily I completely cured this trouble. First of all I strung a couple of wires lengthways of the garage and suspended them. as nearly as possible over that portion of the floor where the cars are lined up for overhauling. The leads to the hand-lamps were then

held up against the wire by means of small insulated rings, and it was then possible to run each lamp along the wires from one end of the garage to the other as required. In addition, I attached a length of fairly strong round indiarubber, which, as a matter of fact, is ordinary rubber tubing about in. diameter, to the end of each lamp lead. The other ends of the rubber I. attached to each respective lamp-holder.

"This arrangement was particularly useful, as when a man had finished with the light, he simply released his grip and the rubber tubing caused the lamp to be suspended well out of the way of the machines and the benches."

When Making Brass-wire Rings.

[1393] " J.G.P." (Luton) writes :—" I have gained many a good tip from your 'D. and M.' pages, and now send you one of my own which may be of use to other mechanics who read those pages. I had a. large number of rings to make from -A in. round brass wire. The inside diameter of the rings was to be 11 in. The job was tackled in the following manner :— " Obtaining a piece of steel tube of lei in. outside diameter, 6 ins. long, I wound around this thil brass wis..c from which the rings were to be made. I then cut the spiral winding and, of course, had a good number of rings formed at one time. Then a difficulty presented itself in that the gap between the ends of the rings was in. or more. As I wanted them to fit closely together, the first lot I cut were scrapped. I got over the diffieulty as follows :— " More wire was obtained, and this I re-wound round the tube, and before saw-cutting the windings, I heated both wire and tube in the forge fire, and quenched them quickly in cold water. I then again performed the saw-cutting operation as previously, and was pleased to find every ring came off the tube with the ends butting closely together, and still the 11 in. inside diameter was maintained."

"More Than Satisfied with the Investment."

[1391] " HI." (liamsgate) writes :—" I enclose a photograph [We reproduce this.—En.] of a smartlooking char-h-bancs in the form of a 32 h.p. Albion machine. My employer, Mr. Griggs, of -Dampton Farm, Ramsgate, who is the owner, decided this year to go in seriously for passenger transport by motor, considering that it was time to supersede his horsedrawn brakes.

"He first purchased two new Albions, and soon afterwards increasing business caused him to acquire an additional two machines, his second choice being Straker-Squire make.

"We have done exceptionally well this season in the. matter of char-h-bancs work, and Mr. Griggs tells me he is more than satisfied with the results of his investment.

" Three of the machines are used on pleasure trips around Ramsgate and district, whilst. one is in public service at Margate."