A CABLE SYSTEM OF PLOUGHING.

Page 18

Page 19

If you've noticed an error in this article please click here to report it so we can fix it.

A Description of an Outfit Built by a French Maker of World-wide Repute.

ONE OF THE DIFFICULTIES that has been experienced in connection with the use of single-plough tractors, that is to say, those that drive and do the ploughing on the self-contained one machine principle, is the impossibility of ploughing to certain depths, as only a few limited inches of soil can, as a rule, be furrowed unless the soil is of a very light or sandy nature.

In many countries the arable land is composed of heavy, sticky soil, and the farmer can only plough his fields on certain occasions when the weather is favourable ; he thus misses weeks before his land is prepared for the sowing of future crops. In consequence some of the light, or even heavy agrimotors are unable to be employed to the satisfaction of users at chosen periods, which is naturally most unsatisfactory during the rainy season, which, as a matter of fact, is the proper moment when many fields should be undergoing the process of ploughing. Of late years, in France, much use has been made of the cable system of ploughing which is claimed to be, by its exponents, the only form of ploughing which can be undertaken in any weather upon any class of soil.

It may be argued that the primary outlay of the twin tractor cable system which this form of ploughing involves is somewhat high, or relatively expensive, but farmers having large areas to cultivate, either in England or, for that matter, in the Overseas Dominions, would not hesitate to agree to advance the capital outlay providing they could be assured of the advantages of the system.

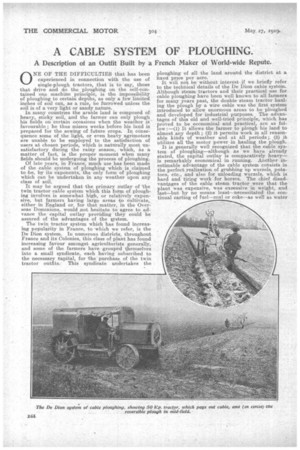

The twin tractor system which has found increasing popularity in France, to which we refer, is the De Dion system. In numerous districts, throughout France and its Colonies, this class of plant has found increasing favour amongst agriculturists generally, and some of the farmers have grouped themselves into a small syndicate, each having subscribed to the necessary capital, for 'the purchase of the twin tractor outfits. This syndicate undertakes the ploughing of all the land around the district at a fixed price per acre. It will not be without interest if we briefly refer to the technical details of the De Dion cable system. Although Steam tractors and their practical use for cable ploughing have been well known to all farmers for many years past, the double steam tractor hauling the plough by a wire cable was the first system introduced to allow enormous areas to be ploughed and developed for industrial purposes. The advantages of this old and well-tried principle, which has proved to be economical and practical, are as follow :—(l) It allows the farmer to plough his land to almost any depth ; (2) it permits work in all reasonable kinds of weather and at all periods; (3) it utilizes all the motor power in hauling the plough. It is generally well recognized that the cable system of ploughing—although as we have already stated, the capital outlay is comparatively heavy— is remarkably economical in running. Another inestimable advantage of the cable system consists in the perfect realization of grubbing up wurzels, potatoes, etc., arid also for unloading wurzels, which is hard and tiring work for horses. The chief disadvantages of the cable steam tractor :were that the plant was expensive, was excessive in weight, and last—but by no means least—necessitated the continual carting of fuel—coal or coke—as well as water o the dual position of the tractor.This latter in;onvenience is avoided in the modern plant by re )1acing the steam engine by a petrol-propelled unit. Two complete sets of this kind of plant are made )3, the De Dion Co., the first employing a 50 h.p. mit, and the second a 35 h.p. unit. Each complete et is composed of two tractors, each one of which s fitted with an engine which can be utilized either or driVing the tractor on the road or for 'working he windlase When upon the fields. A. to-a.y )lough, perfectly balanced, is also supplied. Each .ractor is built on a robust chassis, specially dedgned to receive the windlass, around which is vound the wire cable.

The engine of the 50 h.p. vehicle is four-cyliniered, of 125 ram. bore and 150 mm. stroke, and has speed of 1,000 to 1,200 r.p.m. The carburetter is if De Dion's own make, made under Zenith licence ;

petrol or benzole can be utilized as a uel. The De Dion well-known friction plate clutch is used, and the gearbox arovides two speeds forward and reirerse. Transmission is by transverse ghaft and reducing gear inside the wheel. The front wheels are 40 ins. liameter and the rear wheels 56 ins. Special V-shaped steel spuds, easily detachable, are fitted to the rear wheels Lo increase adhesion. When used for road purposes, the speed of the tractor L'ail be increased to 5 m.p.h. ; on the land, its speed can be reduced to 1 m.p.h., which, it will be readily agreed, allows of easy manipulation in the worst of fields. The tractor can be made to turn in a circumference of about eight yards. The working speed of the plough when drawn by the windlass is about an average of 2 m.p.h.' which allows a six-share plough to be fitted and to furrow to a depth of 10 ins, on ordinary soil ; with a three-share plough s depth of 14 ins, can be attained. For an average elf ort of 2.1 tons upon the wire cable, ploughing at a depth of between 7 ins. to 10 ins., with a six-share plough, the consumption of fuel, it is stated, would be three to four gallons of petrol per acre ploughed ; in this case about one acre of land would be ploughed per hour. For an effort of 31 tons, and ploughing to a depth of 14 ins. with three shares, the consumption per acre would be approximately from seven to ten gallons, whilst the average amount of ground ploughed would be about six acres for a 10-hour working day.

The weight of the 50 hp. tractor complete and ready for the road is about 6 tons.

The features of the 35 h.p. set are practically identical with those of the heavier plant, but the dimensions of the four-cylinder engine in this case

-.are -100 ram. 'boreby 1,1& min. stroke. Other engine details conform to those specified in •the N h.p. type. In this model only one speed is provided in each direction and the transmission to driving wheels is by chain. The front wheels are of 28 ins, diameter and the rear oaies 48 ins.' diameter. When employed for road haulage' this tractor can attaina speed of frow two to three Miles Per hour. When used on the ..field or upon bad soil, by simply changing the -chain pinion, the speed can be reduced to one .or. two miles per hour. The turning facilities are easy, as it can turn .round in a circumference of about eight yards. The ploughing speed through the cable from the windlass is on an average . of over two. miles per hour but nearly three miles per hour can be attained. The useful drawbar pull from the head of the plough is about an average of two tons. This allows upon ordinary soil ploughing with four

shares to a depth of 10 ins, over a width, in this case, of 4 ft., and with two shares to a depth of 14 ins, over a width of 2 ft. 8 ins.

For an average pulling effort of 2 tons upon the wire cable and when ploughing to a depth of from 7 ins. to 10 ins, with four shares, the consumption of petrol per acre is between three to fwe gallons. In the above ease and considering the speed and the width of ground upon each journey, the average surface ploughed would be about six acres for a 10-hour working day. For the same effort of 2 tons, as above, ploughing to a depth of 14 ins, with two shares, the consumption of petrol would be five to six gallons per acre.

The weight of the tractor ready for the road is about four tons.