A COMBINED PETROL AND STEAM ENGINE

Page 14

Page 15

If you've noticed an error in this article please click here to report it so we can fix it.

Description of the Still Engine in which the Otherwise Wasted Heat from the Engine is Largely Recovered.

IN THE ISSUE of The C ommercial Motor for March 27th we dealt with the question of waste of power, reminding our readers that every fuel has a definite calorific value. and that in any engine the relationship between the output of work in a

certain time on the one hand and the calorific value of the fuel consumed on the other hand gives a numerical quantity known as the thermal efficiency of the engine.

This article was preparatory to the imminent disclosure of the principles of the Still thermal cycle, with which Captain Frank E. D. Acland, M.Inst.C.E., dealt fully in a paper which he read before the .Royal Society of Arts yesterday (Monday), taking as a title for his paper "A New Prime Mover of High Efficiency and British Origin." During the last four and a half years publication of any of the work in connection with the Still engine has been considered inadvisable,

There are two methods of producing power by the combustion of oil—either in boilers or within the main cylinders of internal-combustion engines. Steam has offered many advantages, for the steam engine exerts powerful starting efforts, operates at any speed from start to its designed maximum, can develop more than its rated power at reduced speed, and can carry severe overloads for long periods, but this is accomplished with a loss of 80 per cent, at least of the heat energy contained in the fuel supplied to it, this less being irrecoverable.

The internal-combustion engine shows a far higher heat efficiency, hut it cannot start itself without some external source of power, cannot develop its full power except at full speed, is a poor performer at low speeds, and can only operate on moderate overloads for short periods. There is a loss of over 60 per cent. —nearly 70 per cent.—.in the internal-combustion engine. _ The recovery and efficient use of the waste has been the work of many years of patient research by n36

Mr. William J. Still and others associated with him, the basis of his work being the combining in one engine of the superior thermal cycle at the high temperatures and pressure of the internal-combustion engine with the low thermal cycle of steam obtained from the rejected heat from the internal-combustion cycle. He has aimed % at maintaining the temperature of the cooling water at that of steam at useful pressure in order to improve the efficiency of the engine and usefully to increase the weight of steam.

The Still engine is an engine capable of using in its main working cylinder any form of liquid or gaseous fuel

hitherto employed.recoverable heat which passes trough the surfaces of the internal-combustion cylinder, as well as into the exhaust gases, is employed for the evaporation of steam, which steam is expanded in the combustion cylinder itself on one side of the main piston, whilst the combustion stroke acts on the other side. A very subtle point arises in that the primary object is jot to use the waste heat for raising steam, but first to use it inimproving the thermal conditions of the working cylinder—in other words, the engine ,works at a higher general temperature because the water, instead of being taken into the jacket after passing through a radiator at something under boiling point, as is common practice, actually-enters the jacket at nearly 3500 F., passing into the boiler as

steam and water, where a pressure of 120 lb. to the square inch is provided, to act on the lower side of the piston in the steam cycle. The jacket and cooling water therefore form part of the circulating system of a steam generator, the cooling water entering and leaving the jacket at a constant temperature regulated by the pressure of the steam, the cooling being effected by converting the water into steam without raising its temperature. Excluding radiation loss, which is kept low by lagging, all the heat which passes through the walls is thus usefully recovered in the water as steam.

The temperature of the cylinder wall is uniform over the whole of its exterior 60 surface, and the heat lost to the cooling water at each stage of the cycle—compression, combustion and expa.nsion—is diminished. During compression, 50 owing to the walls being at steam temperature, the incoming charge picks up heat instead of losing it during the

i greater part of the stroke, which s an advantage of the greatest value to the

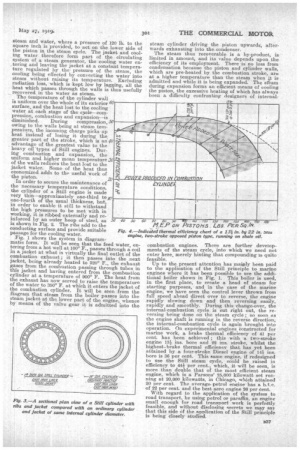

heavy oil -types of Still engines. During combustion and expansion, the uniform and higher mean temperature .30 of the walls reduces the heat lost to the jacket water. Some of the heat thus economized adds to the useful work of the piston. 20 In order to secure the maintenance of the necessary temperature conditions, the cylinder of a Still engine is made very thin—approximately one-third to lo one-fourth of the usual thickness' but, in order to enable it still to withstand the high pressures to be met with in working, it is ribbed externally and reinforced by an outer hoop of steel, as is shown in Fig. 2. The ribs add to the conducting surface and provide suitable passage for the cooling water.

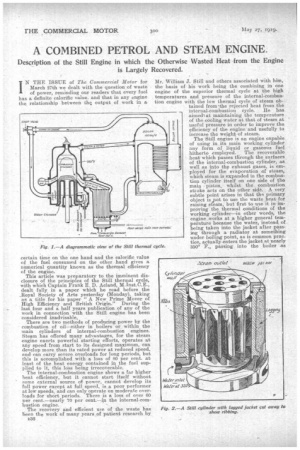

Fig. 1 shows the system in diagrammatic form. It will be seen that the feed water, entering from a hot well at 100° F., passes through a coil in a, jacket at what is virtually the final outlet of the combustion exhaust ; it then passes into the next jacket, being already heated to 320° F., the exhaust gases from the combustion passing through tubes in this jacket and having entered from the combustion cylinder at a, temperature of 900° F. The heat from the exhaust has now served to raise the temperature of the water to 350° F. at which it enters the jacket of the combustion cylinder. It will be seen from the sliagram that steam from the boiler passes into the steam jacket at the lower part of the engine, whence by means of the valve gear it is admitted into the steam cylinder driving the piston upwards, afterwards exhausting into the condenser. The steam thus recoverable is a by-product, is limited in amount, and its value depends upon the efficiency of its employment. There is no loss from condensation because the piston and cylinder walls, which are preheated by the combustion stroke, are at a higher temperature than the steam when izt is admitted and while it is being expanded. The steam during expansion forms an efficient means of cooling the piston, the excessive heating of which has always been. a difficulty confronting designers of internal combustion engines. There are further developments of the steam cycle, into which we need not enter here, merely hinting that compounding is quite feasible.

Up to the present attention has mainly been paid to the application of the Still principle to marine engines where it has been possible to use the additional boiler shown in Fig, 1. This boiler is used, in the first place, to create a head of steam for starting purposes, and in the case of the marine engine, we have seen the control lever thrown from full speed ahead direct over to reverse, the engine rapidly slowing down and then reversing easily, rapidly and smoothly. During this change-over, the internal-combustion cycle is cut right out, the reversing being done on the steam cycle ; so soon as the engine shaft is running in the reverse direction, the internal-combustion cycle is again brought into operation. On experimental engines constructed for marine work, a. brake thermal efficiency of 41 per cent, has been achieved' this with .a two-stroke engine 131 ins, bore and 22 ins, stroke, whilst the bighest.brake thermal efficiency that has yet been attained by a four-stroke Diesel engine of 14 ins. bore is 36 per cent. This same engine, if redesigned to use the Still steam cycle, could be raised in efficiency to 443per cent., which, it will be seen, is more than double that of the most efficient steam engine, which is a Parsons' 25,000 kilowatt set running at 20,000 kilowatts, hi Chicago, Which attained 20 per cent. The averagepetrol engine has a b.t.e. of 22 per cent. and the best aero engine 26 per cent.

With regard to the application of the system to road transport, by using petrol or paraffin, an engine small enough for road transport work is perfeetly feasible, and without disclosing secrets we may say that this side of the application of the Still principle is being closely studied.