Nom Drivers &Mechanics

Page 19

If you've noticed an error in this article please click here to report it so we can fix it.

We pay for contributions on this page at the rate of one penny a line of ten words published, with an allowance for photographs. Communications of special merit will be paid for at a higher rate.

Light Up Your Lamps At

8.59 on Thursday ; 9.0 on Friday ; 9.1 on Saturday; 9.3 on Monday ; 9.4 on Tuesday ; 9.5 on Wednesday.

A Home-made Drilling Machine.

[1631] "A.L." (Burnley) writes :—"There must be many wayside garages, like my own, devoid of all machinery, where the presence of some such tool as that which I am about to describe would be a boon. I have frequently found it necessary to drill holes in steel or other hard material, in some cases upwards of in. thick. If there are many of these to do, and the only tool available is the usual breast-drill, the work becomes very tedious.

"I have on previous occasions seen descriptions of methods in which the breast-drill has been embodied, supplemented by mechanical means of applying the necessary pressure between drill and work, and also of feeding the drill along. These all fail after a short period of use, owing to the fact that a much greater thrust is put on the bearings of the machine than they are designed to bear. "In the sketch I enclose-[which we have had redrawn.—Eul—I describe a machine, made by myself, wherein I have utilized the joiner's brace type of tool, strengthened in order to withstand the smusual endwise pressure. _The bottom portion of_the stand, as well as the cross-bar, are of oak. The base is covered on the top by a plate of sheet steel, drilled at intervals for the reception of stop-pegs.

." Beyond this I think the sketch, with explanatory notes thereon, explains itself. The brace is made from in. diameter bar iron, with a hardened steel tip driven in to its upper end. The lower end is prepared for a drill chuck, or, alternatively, for diamond-pointed hand-made drills. The first adjustment for height is made by moving the cross-bar up or down. The feed is applied by means of the handwheel shown."

Brackets of Sheet-metal.

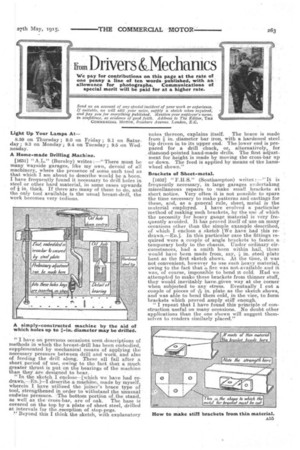

[1632] "F.H.S." (Southampton) writes :—" It is frequently necessary, in large garages undertaking miscellaneous repairs to make small brackets at short notice. Very often it is not possible to spare the time necessary to make patterns and castings for these, and, as a general rule, sheet, metal is the material employed. I have evolved a particular method of snaking such brackets, by the use af which the neceosity for heavy gauge material is very frequently avoided. It has proved itself of use on many occasions other than the simple example described, of which I enclose a .sketch [We have had this redrawn.—End. In this particular case the fittings required were a couple of angle brackets to fasten a temporary body to the chassis. Under ordinary circumstances, had a smith been within hail, these would have been made from, say, in. steel plate bent as the first sketch shows. At the time, it was not convenient, however to use such heavy material, owing to the fact that a fire was not,. available and it was, of course, impassible to bend it cold. Had we attempted to make these brackets from thinner stuff, they would inevitably have given way at the corner when subjected to any stress. Eventually I cut a .couple of pieces of ir in. plate as the sketch shows, and was able to bend them cold, in the vice, to form brackets which proved amply stiff enough.

"I repeat that I have found this principle of construction useful on many occasions. No doubt other applications than the one shown will suggest themselves to readers similarly placed."