HAUL Ell'S CHOICE

Page 32

Page 34

Page 35

Page 36

Page 37

If you've noticed an error in this article please click here to report it so we can fix it.

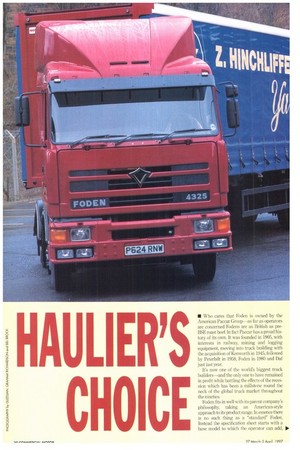

• Who cares that Foden is owned by the American Paccar Group—as far as operators are concerned Fodens are as British as preBSE roast beef. In fact Paccar has a proud history of its own. It was founded in 1905, with interests in railway, mining and logging equipment, moving into truck building with the acquisition of Kenworth in 1945, followed by Peterbilt in 1958, Foden in 1980 and Daf just last year.

It's now one of the world's biggest truck builders—and the only one to have remained in profit while battling the effects of the recession which has been a millstone round the neck of the global truck market throughout the nineties.

Foden fits in well with its parent company's philosophy, taking an American-style approach to its product range. In essence there is no such thing as a "standard" Foden. Instead the specification sheet starts with a base model to which the operator can add, choosing from the widest range of options of any European manufacturer. All Foden trucks are built to order.

• EVOLUTION

Perhaps because of its American parentage, the only three-axle tractor Foden would consider building until 1988 was a 6x4. Then, under pressure from its customers, it introduced a tag-axle model, followed the next year with a twin-steer.

When the 4000 Series tractor appeared at the beginning of 1987, three engine manufacturers provided it with an incredibly large choice of power Options.

Because of Caterpillar's success in earthmoving equipment the 10-litre 300hp and 14.6-litre 350hp Cat engines found favour in the construction sector. Cummins offered its 10-litre L10 325 and long-serving 14-litre E320 and E350, followed by the 500hp option. In 1991 Perkins joined in with the 300Tx, 325Tx and 375Tx; the 350hp version joined Foden's spec list in 1992.

This, and the fact that Caterpillar didn't choose to conform to Euro-1 emission legislation, may explain why Cummins upratecl its L10 to 350hp with electronic engine management: Foden adopted it in 1994 and followed it up with the Cummins 11-litre Euro-2 M1 1 engine the following year. Caterpillar's Euro-2 range of engines was put back on the list too.

Was there ever such a choice of transmissions? Fuller's nine and 13-speed gearboxes compete alongside Eaton's 12-speed constant

mesh Twin Splitter and more recently 16speed synchromesh units. For suspension, take your choice from rubber, steel and air.

The standard 4000-Series GRP day and sleeper Hi-line cab is complemented by an even taller top sleeper; the list even extends to a narrow 3000 Series version. The 4000 Series cab was face-lifted in 1995; the even bigger XL version was added to the range last year.

• OPERATORS

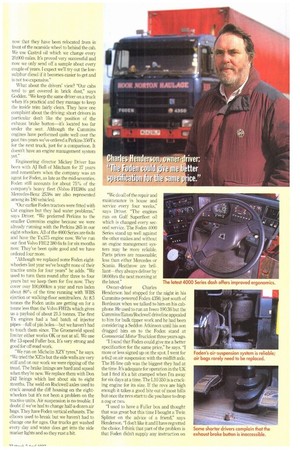

Fleet engineer Alan Godden looks after a fleet of eight-wheelers and drawbar combinations for Thomas Transport, which operates a brick and block transport operation throughout the Home Counties from Northiam, Kent. Ten years ago he and two partners formed a management consortium to buy out the company from the Wolsey Group; today they run 20 trucks including ten four-wheelers which form the company's truck-hire division.

"We have four Fodens altogether and the rest are ERFs," he says. "Why do we run them? They're light; they don't rust and they're a little bit English. Two of the Fodens are M-reg tandem-drive-axled drawbar units running at 38 tonnes with the Cummins L10 350 Celect engines. Drawbars are more economical to operate; they're better for our type of work than artics. They give us a 24-tonne payload with a bit of leeway and, with closeaxled trailers, we find they give us easier access on to construction sites.

"We specified the narrow 3000 Series cab to give us a little more swing clearance," he adds, "but they are still wide enough to take a 6ft bunk. In most other respects the trucks are identical to the 4000 Series. We cover about 80,000km a year with a small percentage of

back loads. Fuel consumption is about 7mpg. That doesn't sound so good but the engine provides the hydraulic power for the crane to unload. When a truck leaves the yard in the morning the engine runs all day, apart from rest breaks.

"In the early days the synchro rings would break up inside the gearbox but, since 1989, we have had very little problem with the Twin Splitter," says Godden. "Just recently we realised that one of the Celect engines was giving less power than the other. The cause was tracked down to a crack in the intercooler casing. It's been changed and seems to be better. Overall the engines' electronics appear to be quite reliable but they can be upset by small faults—a chafed wire feed to the oil pressure switch was sufficient to cut the engine dead a couple of times. I wonder what they will be like after a few more years but I won't worry if we can carry out 90% of the maintenance and they don't incur too much downtime. We tend to keep our trucks for 10 to 12 years and then break them for parts.

"Tyres do very well if they don't get damaged on site," he reports. "We ask for Michelins and got 170,000km from the front drive axle. On the steer axle we find that XZEls last 50% longer than XZAs and there isn't much difference in the price. Commercial Tyres of Ashford recycle our own casings and return them as remoulds.

"Brakes are a heavy toll," he says. "They are efficient but we aren't happy with the mileage. The auto adjusters are too sensitive. Air suspension is noticeably less damaging to the load: we've not had to do anything to the airbags in four years apart from replacing a self-levelling valve. Air filters stay cleaner now that they have been relocated from in front of the nearside wheel to behind the cab. We use Castrol oil which we change every 20,000 miles. It's proved very successful and now we only send off a sample about every couple of years. I expect we'll try out the lowsulphur diesel if it becomes easier to get and is not too expensive."

What about the drivers' view? "Our cabs tend to get covered in brick dust," says Godden. "We keep the same driver on a truck when it's practical and they manage to keep the inside trim fairly clean. They have one complaint about the driving: short drivers in particular don't like the position of the exhaust brake button—it's located too far under the seat. Although the Cummins engines have performed quite well over the past two years we've ordered a Perkins 350Tx for the next truck, just for a comparison, It doesn't have an engine management system yet."

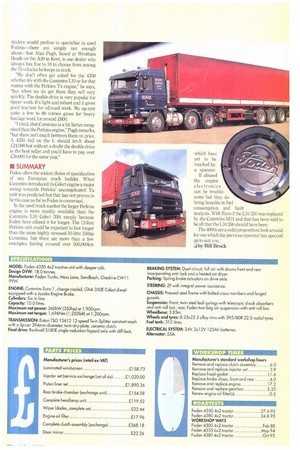

Engineering director Mickey Driver has been with AJ Bull of Mitcham for 27 years and remembers when the company was an agent for Foden, as late as the mid-seventies. Foden still accounts for about 75% of the company's heavy fleet (Volvo FH380s and Mercedes-Benz 2538s are also represented among its 180 vehicles).

"Our earlier Fe(len tractors were fitted with Cat engines but they had water problems," says Driver. "We preferred Perkins to the smaller Cummins engine because we were already running with the Perkins 265 in our eight-wheelers. All of the 4000 Series are 6x4s and have the Tx375 engine now. We've run our first Volvo FH12 380 6x4s for six months now. They've been quite good and we have ordered four more, "Although we replaced some Foden eightwheelers last year we've bought none of their tractive units for four years" he adds. "We used to turn them round after three to four years but we keep them for five now. They cover over 100,000km a year and run laden about 80% of the time running with WBS ejection or walking-floor semitrailers. At 8.5 tonnes the Foden units are getting on for a tonne less than the Volvo FH12s which gives us a payload of about 21.5 tonnes. The first Tx engines had a bad batch of injector pipes—full of pin holes—but we haven't had to touch them since. The Groeneveld speed limiter either works OK or not at all. We use the 13-speed Fuller box. It's very strong and good for off-road work.

"We run on Michelin XZY tyres," he says. "We tried the XZls but the side walls are very stiff and on our work we were ripping off the tread. The brake linings are hard and squeal when they're new. We replace them with Don 242 linings which last about six to eight months. The weld on Rockwell axles used to crack around the diff housing on the eightwheelers but it's not been a problem on the tractive units. Air suspension is no trouble. I doubt if we've had to change half -a-dozen air bags. They have Foden vertical exhausts. The elbows used to break but we haven't had to change one for ages. Our trucks get washed every day and water does get into the side marker lights and so they rust a bit. "We do all of the repair and maintenance in house and service every four weeks," says Driver. "The engines run on Gulf Superfleet oil which is changed every sec ond service. The Foden 4000 Series stand up well against the other makes and without an engine management system may be more reliable.

Parts prices are reasonable; less than either Mercedes or Scania. Heathrow are bril liant—they always deliver by 08:00hrs the next morning at the latest."

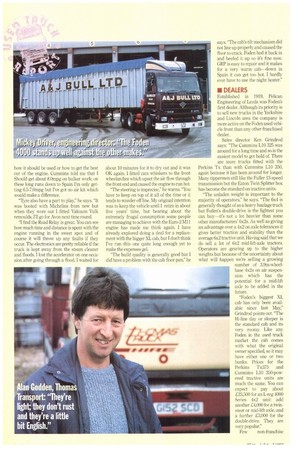

Owner-driver Charles Henderson had stopped for the night in his Cummins-powered Foden 4350, just south of Bordeaux when we talked to him on his cabphone. He used to run an Iveco 190.36 but the Cummins/Eaton/Rockwell driveline appealed to him for bulk tipper work and he had been considering a Seddon Atkinson until his son dragged him on to the Foden stand at Commercial Motor Tr uckfest three years ago.

"I found that Foden could give me a better specification for the same price," he says, "I more or less signed up on the spot. I went for a 6x2 on air suspension with the midlift axle. The Hi-line cab was the biggest they had at the time. It's adequate for operation in the UK but I find it's a bit cramped when I'm away for six days at a time. The L10 350 is a cracking engine for its size. If the revs are high enough it takes a good bite out of most hills but once the revs start to die you have to drop a cog or two.

"I used to have a Fuller box and thought that was great but this time I bought a Twin Splitter on the advice of a friend," says Henderson. "!don't like it and I have regretted the choice. I think that part of the problem is that Foden didn't supply any instruction on how it should be used or how to get the best out of the engine. Cummins told me that I Should get about 8.0mpg on bulker work; on these long runs down to Spain I'm only getting 6.5-7.0mpg but I've got no air kit which would make a difference.

"Tyre also have a part to play," he says. "It was booted with Michelins from new but when they wore out I fitted Vakuum Vulk remoulds. I'll go for Avon next time round.

"1 find the Road Relay is great You can see how much time and distance is spent with the engine running in the sweet spot and of course it will throw up any faults if they occur. The electronics are pretty reliable if the truck is kept away from the steam cleaner and floods. I lost the accelerator on one occasion after going through a flood. I waited for about 10 minutes for it to dry out and it was OK again. I fitted cats whiskers to the front wheelarches which upset the air flow through the front end and caused the engine to run hot.

"The steering is imprecise," he warns. "You have to keep on top of it all of the time or it tends to wander off line. My original intention was to keep the vehicle until I retire in about five years' time, but hearing about the extremely frugal consumption some people are managing to achieve with the Euro-2 Mll engine has made me think again. I have already explored doing a deal for a replacement with the bigger XL cab, but I don't think I've run this one quite long enough yet to make the expenses gel.

"The build quality is generally good but I did have a problem with the cab floor pan," he says. "The cab's tilt mechanism did not line up properly and mused the floor to crack. Foden had it back in and beefed it up so it's fine now, GRP is easy to repair and it makes for a very warm cab—down in Spain it can get too hot. I hardly ever have to use the night heater."

• DEALERS

Established in 1919, Pelican Engineering of Leeds was Foden's first dealer. Although its priority is to sell new trucks in the Yorkshire and Lincoln area the company is more active on the Foden used vehicle front than any other franchised dealer.

Sales director Ken Grindrod says: "The Cummins L10 325 was around for a long time and so is the easiest model to get hold of. There are more trucks fitted with the Perkins Tx than with Cummins L10 350, again because it has been around for longer. Many tippermen still like the Fuller 13-speed transmission but the Eaton Twin Splitter box has become the standard on tractive units.

"The unladen weight is important to the majority of operators," he says. "The 6x4 is generally thought of as a heavy haulage truck but Foden's double-drive is the lightest you can buy—it's not a lot heavier than some other manufacturers' 6x2s. As well as giving an advantage over a 4x2 on axle tolerances it gives better traction and stability than the average 6x2 tractive unit. Having said that we do sell a lot of 6x2 mid-lift-axle tractors. Operators are gearing up to the higher weights but because of the uncertainty about what will happen we're selling a growing number of 3.9m-wheelbase 4x2s on air suspension which has the potential for a mid-lift axle to be added in the future.

"Foden's biggest XL cab has only been available since last May," Grindrod points out. "The Hi-line day or sleeper is the standard cab and its very roomy. Like any Foden in the used truck market the cab comes with what the original owner specified, so it may have either one or two bunks. Prices for the Perkins Tx375 and Cummins L10 350-powered tractive units are much the same. You can expect to pay about .E23,500 for an L-reg 4000 Series 4x2 unit: add another .C4,000 for a twinsteer or mid-lift axle, and a further .f3,000 for the double-drive. They are very popular."

Few non-franchise dealers would profess to specialise in used Fodens—there are simply not enough about—but Alan Pugh, based at Wrotham I leath on the A20 in Kent, is one dealer who always has five to 10 to choose from among the 75 vehicles he keeps in stock.

"We don't often get asked for the 4350 whether it's with the Cummins L10 or for that matter with the Perkins Tx engine," he says, "but when we do get them they sell very quickly. The double-drive is very popular for tipper work. It's light and robust and it gives good traction for off-road work. We up-rate quite a few to 80 tonnes gross for heavy haulage work for around .£600.

"I think that Cummins is a bit better recognised than the Perkins engine," Pugh remarks, "but there isn't much between them on price. A 4350 4x2 on the L should fetch about £24,000 but without a doubt the double-drive is the best seller and you'd have to pay over 1:30,000 for the same year."

• SUMMARY

Foden offers the widest choice of specification of any European truck builder. When Cummins introduced its Celect engine a major swing towards Perkins' uncomplicated Tx unit was predicted but that has not proven to be the case as far as Foden is concerned.

In the used truck market the larger Perkins engine is more readily available than the Cummins L10 Celect 350; simply because Foden have offered it for longer. The 12-litre Perkins unit could be expected to last longer than the more highly stressed 10-litre 350hp Cummins, but there are more than a few examples having covered over 500,000km which have yet to be touched by a spanner.

If abused the engine electronics can be troublesome but they do bring benefits in fuel consumption and fault analysis. With Euro-2 the L10 350 was replaced by the Cummins Mll and that has been said to be all that the L10 350 should have been.

The 4000s are a solid proposition; look around for one which the previous operator has specced up to suit you.

=I by Bill Brock