New Retracting Semi-trailer Turntable Attachment

Page 35

If you've noticed an error in this article please click here to report it so we can fix it.

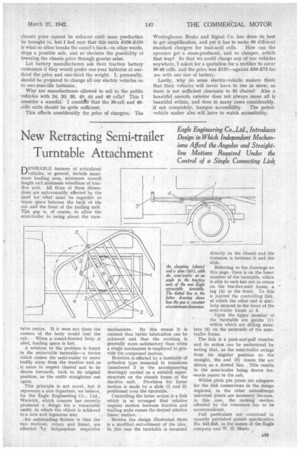

DESIRABLE features of articulated vehicles, in general, include maximum loading area, minimum overall length and minimum wheelbase of tractive unit. All three of these dimensions are unfavourably affected by the need for what must be regarded as waste space between the back of the Cab and the front of the trailing unit. This gap is, of course, to allow the semi-trailer to swing about the turn

table centre. If it were not there the corners of the body would foul the cab. When a round-fronted body is uSed, loading space is lost.

A solution to the problem is found in the retractable turntable—a device which causes the seini-trailer to move bodily away from the tractive unit as it turns in respect thereof and to be drawn forwards, back to its original position, as the outfit straightens out again.

This principle is not novel, but it represents a new departure, we believe, for the Eagle Engineering Co., Ltd., Warwick, which 'concern has recently produced a design for a retractable outfit, in which the object is achieved in-a new and ingenious way.

-An outstanding feature is that the two motions, rotary and linear, are afforded 'by independent respective

mechanisms. By this means it is claimed that better lubrication can be achieved and that the working is generally more satisfactory than when a single mechanism is employed to provide the compound motion.

Rotation is effected by a turntable of orthodox type mounted in trunnions (numbered 3 in the accompanying drawings) carried on a suitable superstructure on the chassis frame of the tractive unit. Provision for linear motion is made by a slide (I. and 2) positioned over the turntable..

Controlling the latter action is a link which is so arranged that relative angular motion between tractive and trailing units causes the desired relative linear motion.

Besides the design illustrated there. is a modified embodiment of the idea. In this case the turntable is mounted directly on the chassis and the trunnion is between it and the slide.

Referring to the drawings on this page, there is on the lower member of the turntable, which is able to rock but not to rotate on the tractive-unit frame, a lug (4) at the front. To this is jointed the controlling link, of which the other end is similarly secured to the front of the semi-trailer frame at 5. Upon the upper member of the turntable are guides (I) within which are sliding members (2) on the underside of the semitrailer frame.

The link is a push-and-pull member and its action can be understood by noting that, as the semi-trailer swings from its angular position to. the straight, the end (5) traces the arc shown as a dotted line. This results in the semi-trailer being drawn for'wards nearer to the cab.

Whilst plain pin joints are adequate for the link connections in the design depicted, in the other embodiment universal joints are necessary because, in this case, the rocking motion afforded by the trunnions has to be

accommodated.

Full particulars are contained in recently published patent specification No. 542,845, in the names of the Eagle company and W. H. Meats.