HINTS ON MAINTENANCE.

Page 28

Page 29

If you've noticed an error in this article please click here to report it so we can fix it.

How to Get the Best Out of a. Vehicle, to Secure Reliability and to Avoid Trouble.

351.—Preventing the Deposition of Carbon in Pistons.

One of the troubles experienced with some engines is that the lubricating oil` splashes into the pistons and, coming fnto contact with the interior of the heated head, is turned into carbon, and either then or later _drops down into the crankcase and reduces the lubricating properties of the oil, besides having an abrasive action on the bearings.

Successful experiments have been conducted with a light steel plate sprung into a shallow groove cut round the piston just above the small end, the plate being held in position by means of -a spring ring. This plate arrests the oil splashes, and as this portion of the piston does not get nearly so hot as the top, very little, if any, carbon is likely to be formed.

Care should be taken not to weaken the piston when the groove is being cut. If the plate IS properly made, the groove will only need to be very shallow. It must, of course, be remembered that Messrs. Hepworth and Grandage, of Bedford, make a piston of this type under the name of the Gwynne.

352.—Reassembling the Austin Clutch.

When reassembling an. Austin clutch, difficulty is sometimes experienced in replacing the nut on to the crankshaft behind the clutch withdrawal spring. By placing the tension spring, ball race and nut into the housing and temporarily employing two bolts for coupling up with the clutch cone, the nut can be screwed on to the crankshaft in a few moments. Before removing the tension spring housing in order to ascertain if the nut is screwed up far enough, it will be necessary to place two old bolts of the neces sary length between the clutch cone and the flywheel, otherwise the tension spring will drive in the clutch cone, and a difficulty will be found in again reassembling the housing.

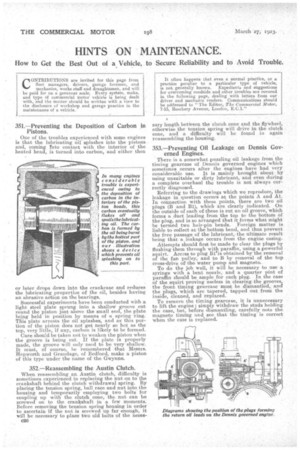

353.—Preventing Oil Leakage on Dennis Governed Engines.

There is a somewhat puzzling oil leakage from the timing gearcase of Dennis governed engines which sometimes occurs after the engines have had very considerable use. It is mainly brought about by using unsuitable or dirty lubricant, and even during. a complete overhaul the trouble is not always correctly diagnosed.

Referring to the drawings which we reproduce, the leakage in question occurs at the points A and Al. In connection with these points, there are two oil plugs (B and B1), which are clearly indicated. On the outside of each of these is cut an oil groove, which forms a duct leading from the top to the bottom of the plug, and is so arranged that it forms what might be termed two hair-pin bends. Foreign matter is liable to collect at the bottom bend, and thus prevent the free passage of the lubricant,. the ultimate result being that a leakage occurs from the engine casing.

Attempts should first be made to clear the plugs by flushing them through with paraffin, using a powerful squirt. Access to plug Bl'is obtained by the removal of the fan pulley, and to B by removal of the top cross-drive of the water pump and magneto.

To do the job well, it will be necessary to use a syringe with a bent nozzle, and a quarter pint of paraffin should be ample for each plug. In the case of the squirt proving useless in clearing the grooves, the front timing gearcase must. be dismantled, and the plugs, which are tapered, tapped out from the inside, cleaned, and replaced.

To remoyb the timing gearcase, it is unnecessary to lift the engine ; simply withdraw the studs holding the case, but, before dismantling, carefully note the magneto timing and see that the timing is correct when the case is replaced. The nut holding the ran pulley has a left-hand thread.. There is also a special machined washer behind the nut, Which tightens up on tea, distance tube, also with a machiniid face. it is-essential, when replacing the pulley, securely to tighten this nut, er a .Serious oil leakage; will occur, as, normally, the machined face acts as an oil seal.

When replacing the aluminium covers of the top, oross-drive, an extremely thin paper joint, smeareti with a little shellac varnish, should be fitted.