Where to Buy your Supplies. t 4 You_Can Get It:At "

Page 21

Page 22

If you've noticed an error in this article please click here to report it so we can fix it.

Th.e G.K. Co., Ltd." (Coventry).—In reply to your query as to retreading your cab tires, you should get into touch with Almagam, Ltd., Almagam Harpenden.

No Throttle in the Induction Pipe.

A carburetter of interesting construction, from the works of Lukin, Ltd., The Ride Newcomcn Street, Borough, London, S.E., was explained to us by the inventor a few days ago. The feature of the carburetter is the absence of a throttle valve in the induction pipe. In place of this ordinary method of control, one finds an inter-related and inverse movement of the air-inlet above the jet, and of the air-inlet between the jet and the inlet valves of the engine. When the air-inlet above the jet is reduced in area, that between the jet and the inlet valves of the en_gine increases in area, and vice versa. Thus, for example, when it is desired to keep the pulling power of the engine down to a minimum, or to run it light— the equivalent of an ordinary throttle-down position in the average carburetter—there is, by reason of the constriction of the air-inlet between the jet and the engine, a relatively-high vacuum in the induction" pipet and practically only atmospheric pressure above the jet. This compares with the more-usual case of a relatively-high vacuum on the engine side of the throttle-valve, and conditions which more or less tend to favour condensation of petrol between the jet and the throttle valve.

Whilst this carburetter is not yet ready and marketed for engines of greater power than 8 h.p., the inventor and makers are engaged upon the construction and testing of larger sizes, for 15-20 h.p. and also

for 24-30 h.p. engines. We hope, at some early future date, to be in a position to give consumption -figures in gross ton-miles. For the present, we can only recommend Makers of parcelcars and the lightest types of vans to consider the claims of the Lukin patent single-control carburetter, which is described as"constructed on the ortho-metric system." A New Lynton Wheel.

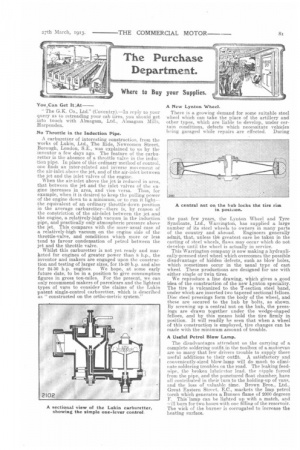

There is a growing demand for some suitable steel wheel which can take the place of the artillery and other types, which are liable to develop, under certain conditions, defects which neoessitate vehicles being garaged while repairs are effected. During the past few years, the Lynton Wheel and Tyre Syndicate, Ltd., Warrington, has supplied a, large number of its steel wheels to owners in many parts of the country and abroad. Engineers generally admit, that, unless tl* greatest care be taken in the casting of steel wheels, flaws may occur which do not develop until the wheel is actually in service. This Warrington company is now making a hydraulically-pressed steel wheel which overcomes the possible disadvantage of hidden -defects, such as blow holes, which sometimes occur in the usual type of cast wheel. These productions are designed for use with either single or twin tires.

We reproduce a line drawing, which gives a good idea, of the construction of the new Lynton speciality. The tire is vulcanized to the T-section steel band, under which are inserted two tapered sectional felloes. Disc steel pressings form the body of the wheel, and these are secured to the hub by bolts, as shown. By screwing up a central nut on the hub, the pressings are drawn together under the wedge-shaped fellows, and by this means bold the tire firmly in position. It will readily be seen that when a wheel of this construction is employed, tire changes can be made with the minimum amount of trouble.

A Useful Petrol Blow Lamp.

The disadvantages attendant on the carrying of a complete soldering outfit in the toolbox of a motorvan are so many that few drivers trouble to supply these useful additions to their outfit. A satisfactory and conveniently-sized blow-lamp will do much to eliminate soldering troubles on the road. The leaking feednipe, the broken lubricitor lead. the nipple forced from the pipe, and the punctured float. hamber, have all contributed in their turn to the holding-up of vans, and the loss of valuable time. Brown Bros., Ltd.. Great Eastern Street, E.C., markets the Imp petrol torch which generates a Bunsen flame of 2000 degrees F. This-lamp can be lighted up with a match, and will burn for two hours with one filling of the reservoir. The wick of the burner is corrugated to increase the heating surface.

A Compact Breast Drill.

The problem of drilling an odd corner hole, on work that has left the marlines, is continually occurring in the workshop. It is a wise practice to provide on the fitting bench a reliable and well-constructed breast drill which will do accurate work iii a speedy

manner. The -United Machine Tool Works, 133, Upper Thames Street, E.C. send us a photograph of their " Rapid " high-speed drill of this type. As will be seen from the illustration reproduced herewith, the tool is cleanly designed, and has several good features. Considerable pressure can be applied by the user of the drill when it is in use, and the construction of the various parts is such that it should, with ordinary care, last for many years. The gears are machine cut, and the drive is either high or low speed as the operator requires. The illustration shows this arrangement clearly. The balance has been carefully thought out, and a true three-jaw chuck is provided.

Suitable Bearing Metals.

For many years Willa.ns and Robinson, Ltd., has held a deservedly high reputation amongst engineers for its high-speed electric-light engines. Granted that an engine, pump, or other main factor in a power scheme may be of novel or clever design, its advantage in this respect may easily be neutralized by the incorporation of unsuitable details. A great part of the success of this company's manufactures is undoubtedly due to the original design of the more important parts. This originality has, however, been well-backed-up by the adoption of suitable metals and other component parts and detail fittings, all of which have done their share in maintaining reliable, consistent and economical running.

We have in mind more particularly, when making this statement, the treatment known as the Eatonia process, which is applied to many of the manufactures in special metals produced by this concern tor employment on commercial chassis. The process effects a great improvement in the homogeneity, antifrictional qualities, durability, density and tensile strength of the metals treated. It can be advantageously employed on white and yellow bearing metals, special alloys, valve-spindles, gear-wheels, steering-worms, etc.

So satisfactory has the treatment proved to be in practice, that it allows of castings being used—for instance, on shafts carrying integral collars, feathers, etc.—where previously, owing to the employment of non-corrosive metals and alloys, forgings were essential.This is possible owing to the increased homogeneity and greater tensile strength, together with the elimination of hard or soft spots, which the Eatonia process gives. It will readily be understood then, that much cheaper metals than are general can be used, while at the same time, the lesser-priced products are of much greater strength than the more expensive materials when so treated. The process can be applied without difficulty to bearing-metals which have been run into shells or connecting rods.

We are enabled to reproduce illustrations of microphotographs which show clearly the difference between a sample of phosphor-bronze in its untreated or natural commercial state, and an Eatonia-treated specimen of the same metal. The illustration on the right is of bronze magnified 150 diameters. It shows clearly the coarseness of the metal, which has a tensile strength of 13 tons per sq. in_ The adjoining view shows similar material after Eatonia treatment. The tensile strength of this specimen is 21 tons per sq. in. Willans and Robinson, Ltd., is prepared to grant licences for the use of the process in the works of other manufacturers, and many well-known steam and petrol wagon makers have availed themselves of the opportunity. Amongst these, we are informed, are Alley and McLellan, Lid.; Albion Motor Car Co., Ltd. ; J. Sankey and Sons, Ltd. ; J. I. Thornycroft and Co., Ltd., and many other concerns known to our readers. The company will be pleased to answer any queries regarding this process.